Pugionium cornutum drink and preparation method thereof

A technology of sand mustard and beverages, which is applied in food extraction, food ingredients, food ultrasonic treatment, etc., can solve the problems of poor taste of extracts, achieve the effects of increasing added value, simple preparation process, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of water mustard extract:

[0027] Wash the mustard with room temperature water first, then dry, crush, and pass through a 70-mesh sieve; weigh the mustard and water according to the solid-liquid ratio of 1g:60mL, add it to a container, and place it in an ultrasonic oscillator for 30 minutes; The container was placed in a constant temperature water bath at 90°C and heated in a water bath for 50 minutes; after the heating was completed, it was filtered under reduced pressure while it was hot to obtain an aqueous extract of mustard.

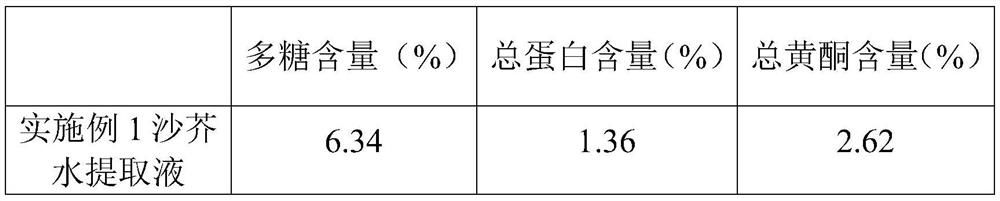

[0028] Measure the content of polysaccharides, total protein and total flavonoids in the obtained mustard water extract solution of embodiment 1 respectively according to the following method:

[0029] Determination method of polysaccharide content: (1) Prepare anhydrous glucose reference substance solution with a concentration of 0.1228mg / mL, measure 0.2, 0.4, 0.6, 0.8, 1.0mL respectively, place in a stoppered test tube, dilute ...

Embodiment 2

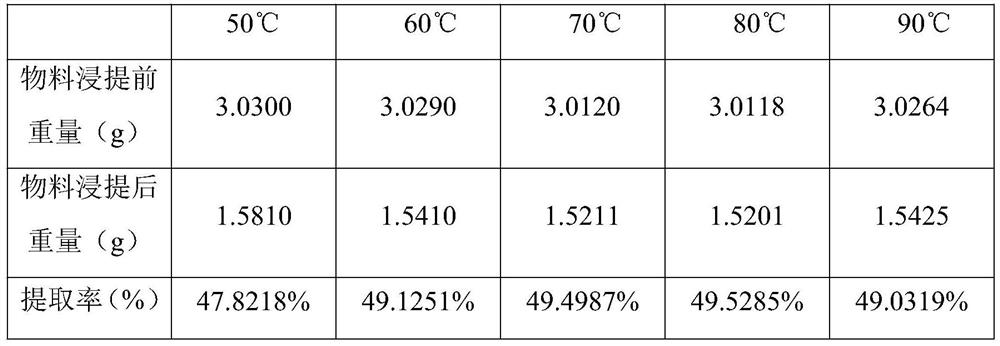

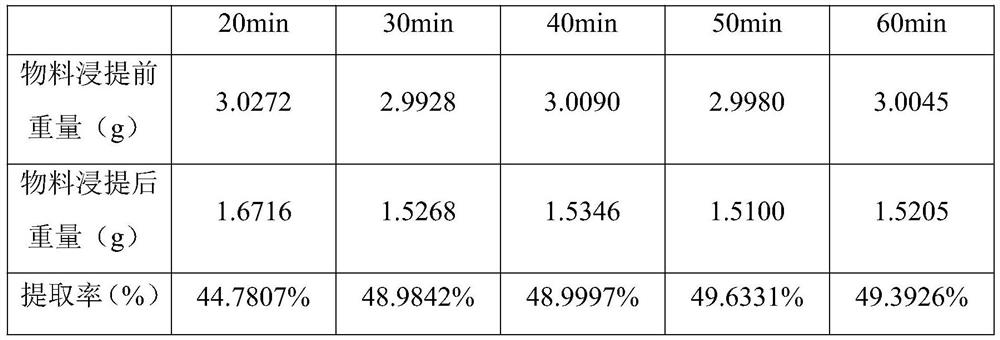

[0035] Determination of the extraction rate of different extraction process parameters of the mustard:

[0036] (1) Wash the mustard with room temperature water first, then dry, pulverize, and pass through a 70-mesh sieve; weigh 5 parts of mustard, each 3g of mustard, and put it into a 250mL triangular flask respectively, according to the ratio of material to liquid: 1g: Add purified water to 60mL, place in an ultrasonic oscillator and shake for 30min; place the shaken triangular flask in a constant temperature water bath (50, 60, 70, 80, 90°C) and heat for 60min. Immediately after the heating is completed, filter under reduced pressure while it is still hot, then place the obtained material and filter paper of known quality in a constant temperature drying oven at (103±2)°C for 1 hour, and dry until constant weight, then calculate the extraction rate; The rate calculation formula is: The results are shown in Table 2:

[0037] Table 2 Extraction rate at different extraction...

Embodiment 3

[0046] Screening of the best extraction process parameters of mustard:

[0047] Carry out L 9 (3 3 ) orthogonal test, the factor levels are shown in Table 5, and the results of the orthogonal test are shown in Table 6.

[0048] Table 5 Orthogonal test factor levels

[0049] Level A heating temperature (℃) B heating time (min) C Ratio of solid to liquid (g / mL) 1 70 40 1:60 2 80 50 1:70 3 90 60 1:80

[0050] Table 6 Orthogonal test results

[0051]

[0052]

[0053] It can be seen from Table 6 that the order of the influence on the extracting amount of the mustard is A>B>C, that is, heating temperature>heating time>solid-liquid ratio. The optimal condition for extracting and extracting A 3 B 2 C 1 , the heating temperature is 90°C, the heating time is 50min, and the ratio of solid to liquid is 1:60. Under these conditions, the effective substances in the mustard can be extracted as much as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com