Method for accurately evaluating comprehensive installation error of two flange plate hole systems

An installation error and flange technology, which is applied in the field of accurate evaluation of the comprehensive installation error of two flange hole systems, can solve the problems of high cost, difficult disassembly and assembly, and increased cost, and achieves low cost and high measurement flexibility. , effects with low hardware and math requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention, and the solutions of the present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

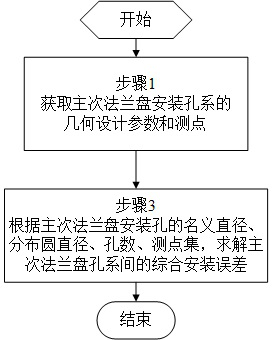

[0038] The precise evaluation method of the comprehensive installation error of the two flange hole systems consists of the following steps (unit: mm, radian):

[0039] Step 1. Obtain geometric design parameters and measurement points.

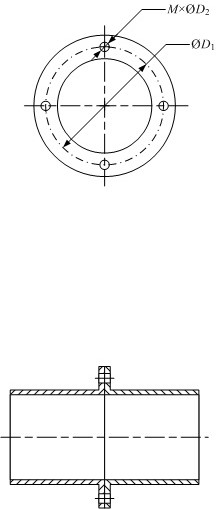

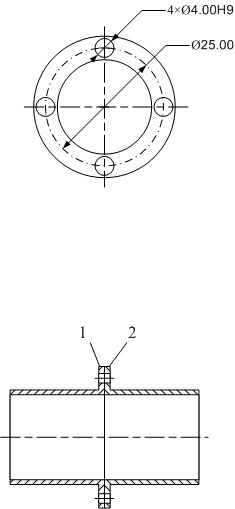

[0040] There is a main flange and a secondary flange on the two parts to be installed; the flanges are all thin plates, and there are mounting holes with the same geometric design on the flanges; each mounting hole consists of 4 mounting holes. The mounting holes are perpendicular to the mounting surface of the flange, and are evenly distributed on a circle with a nominal diameter of 25 in the mounting surface, and the nominal size of the mounting holes is 4.

[0041] Place the mounting surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com