Detection device for high-temperature cable processing and processing technology thereof

A detection device and cable technology, applied in the direction of measuring devices, cable/conductor manufacturing, conductor/cable insulation, etc., can solve the problems of normal use of cables, insufficient raw materials, low efficiency of manual measurement, etc., to ensure the quality of processing and production , Improve the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-7 The application is described in further detail.

[0044] The embodiment of the present application discloses a detection device for high temperature cable processing.

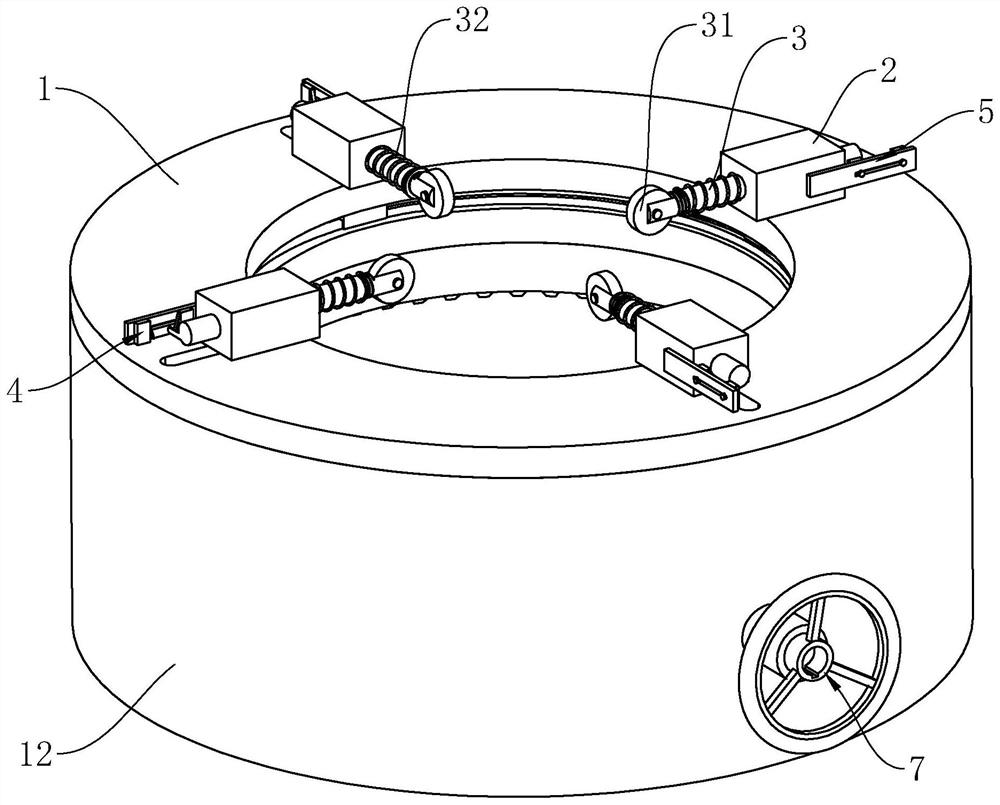

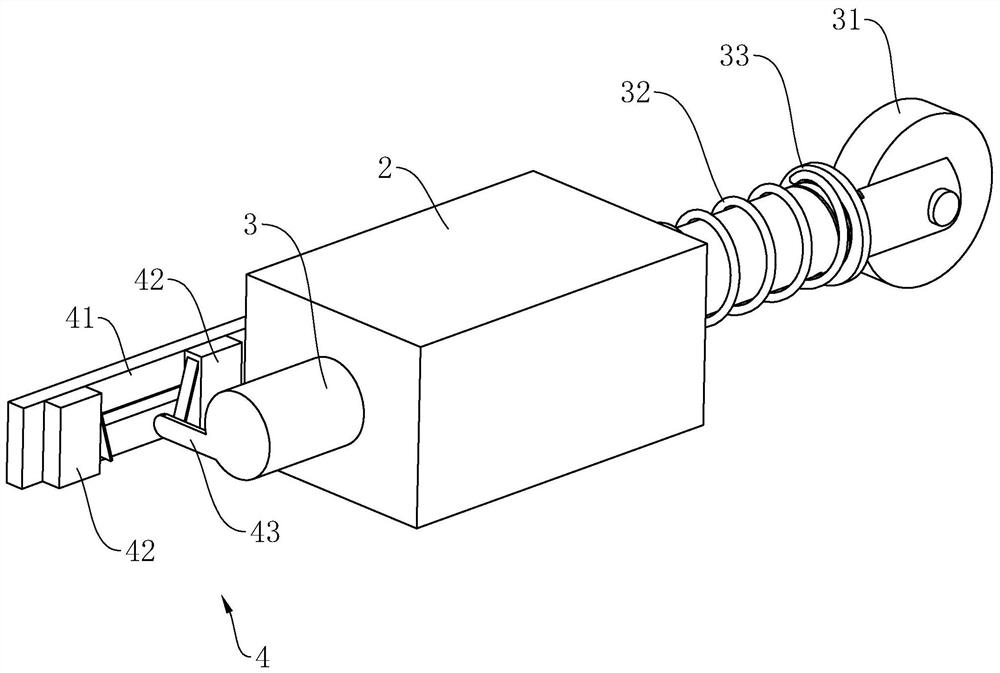

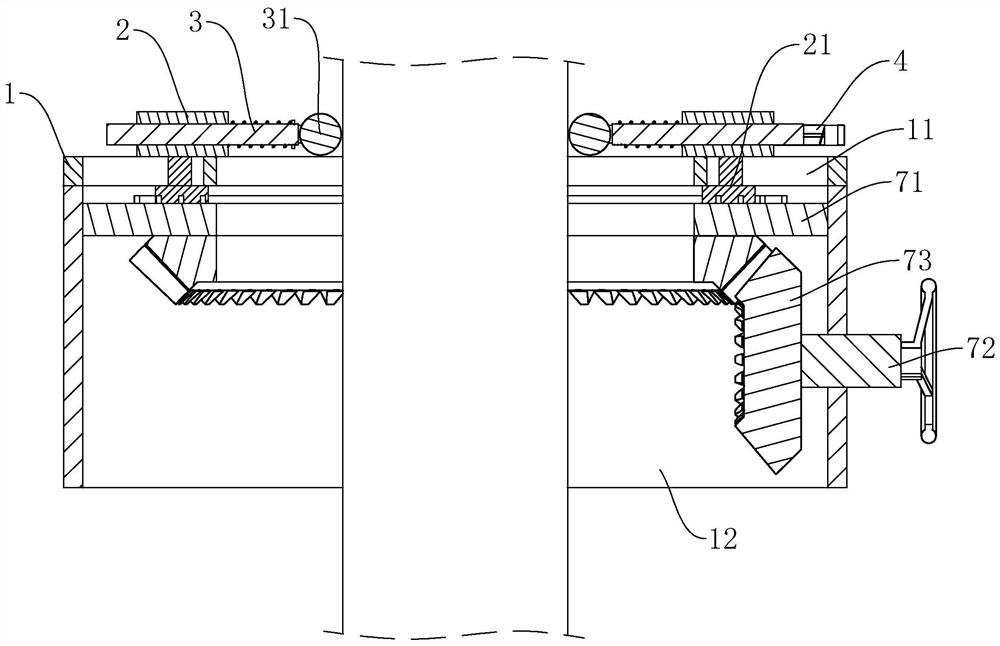

[0045] refer to figure 1 and figure 2 , the detection device includes a mounting ring 1 and a plurality of mounting blocks 2, the axis of the mounting ring 1 is vertically arranged, the inner diameter of the mounting ring 1 is greater than the diameter of the cable to be detected, each mounting block 2 is provided with a detection rod 3, an elastic member And the displacement detection mechanism 4, the cross section of the detection rod 3 is circular, and the detection rod 3 is also arranged along the radial direction of the installation ring 1, the detection rod 3 runs through the installation block 2 and is slidably connected with it, so that the detection rod 3 can be installed Slide on the block 2 along the radial direction of the mounting ring 1. The elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com