A pulse tube refrigerator with co-phase modulation of inertia tube and small hole valve

A pulse tube refrigerator, inertial tube technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve problems such as limitations, and achieve the effects of increased adjustability, high refrigeration efficiency, and good operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

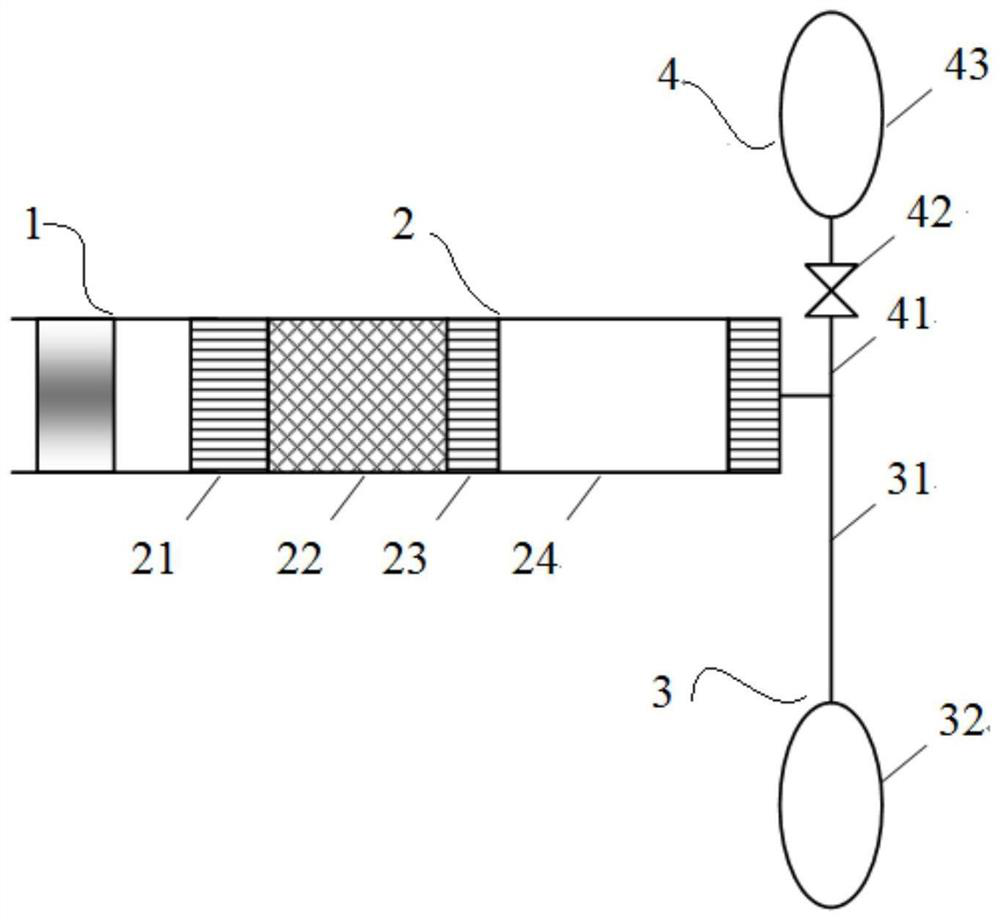

[0040] like figure 1 As shown, this embodiment is a pulse tube refrigerator with a composite phase modulation mechanism in which the inertial tube and the small hole valve are jointly phase-modulated. The pulse tube refrigerator includes a compressor 1 , a pulse tube unit 2 , an inertia tube phase modulator 3 and a small orifice valve phase modulator 4 .

[0041] The pulse tube unit 2 includes a radiator 21, a regenerator 22, a cooling heat exchanger 23, and a pulse tube 24. The end of the pulse tube is respectively connected to the inertial tube phaser 3 and the small hole valve phaser 4, wherein the inertial tube The phaser 3 includes an inertial tube 31 and a gas reservoir 32 at the end of the inertial tube, and the small hole valve phaser 4 includes a connecting pipe 41, a small hole valve 42, and a gas reservoir 43 at the end of the small hole valve, and the end of the small hole valve 42 is connected to the small hole valve. The terminal gas reservoir 43 is connected to...

Embodiment 2

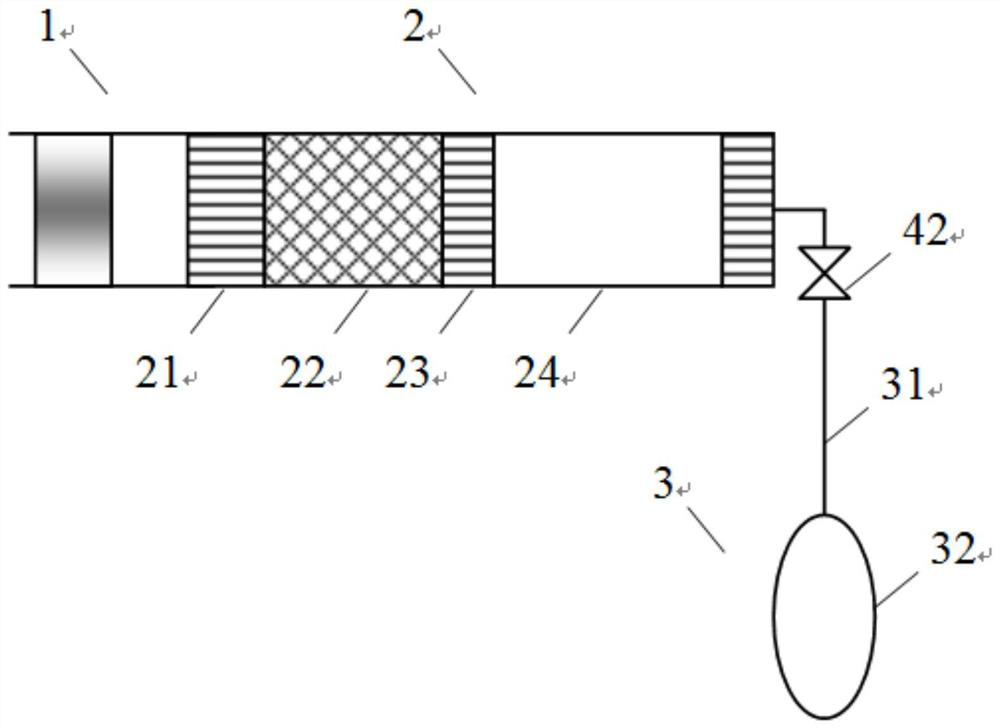

[0044] like figure 2 As shown, in this embodiment, the gas reservoir 43 at the end of the small hole valve in the first embodiment is eliminated, and the gas reservoir 32 at the end of the inertial tube is used as the gas reservoir for the inertial tube 31 and the small hole valve 42 at the same time. The compactness of the structure of the refrigerator is further improved. The rest are the same as in Example 1.

Embodiment 3

[0046] like image 3 As shown, in this embodiment, the small hole valve 42 in Embodiment 1 is placed on the inertial tube 31 , and the inertial tube 31 shares a gas reservoir 32 at the end of the inertial tube. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com