Ball bearing

A ball bearing and steel ball technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of increased friction, increased friction of steel balls, and cumbersome manual operation, and achieves increased strength and increased storage capacity. oily effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

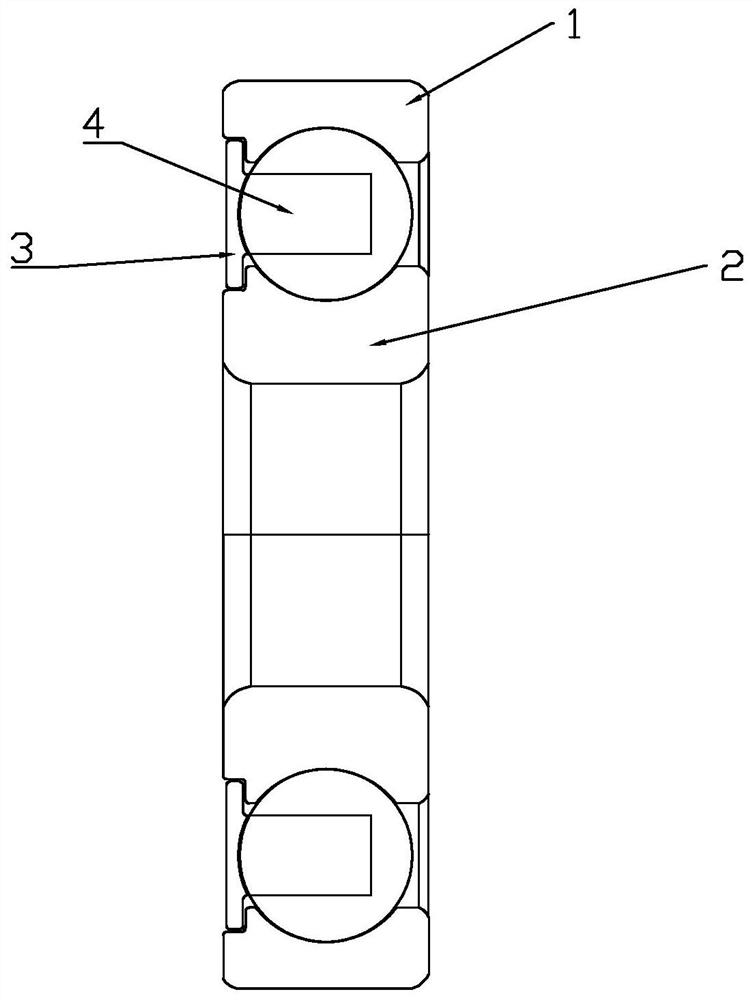

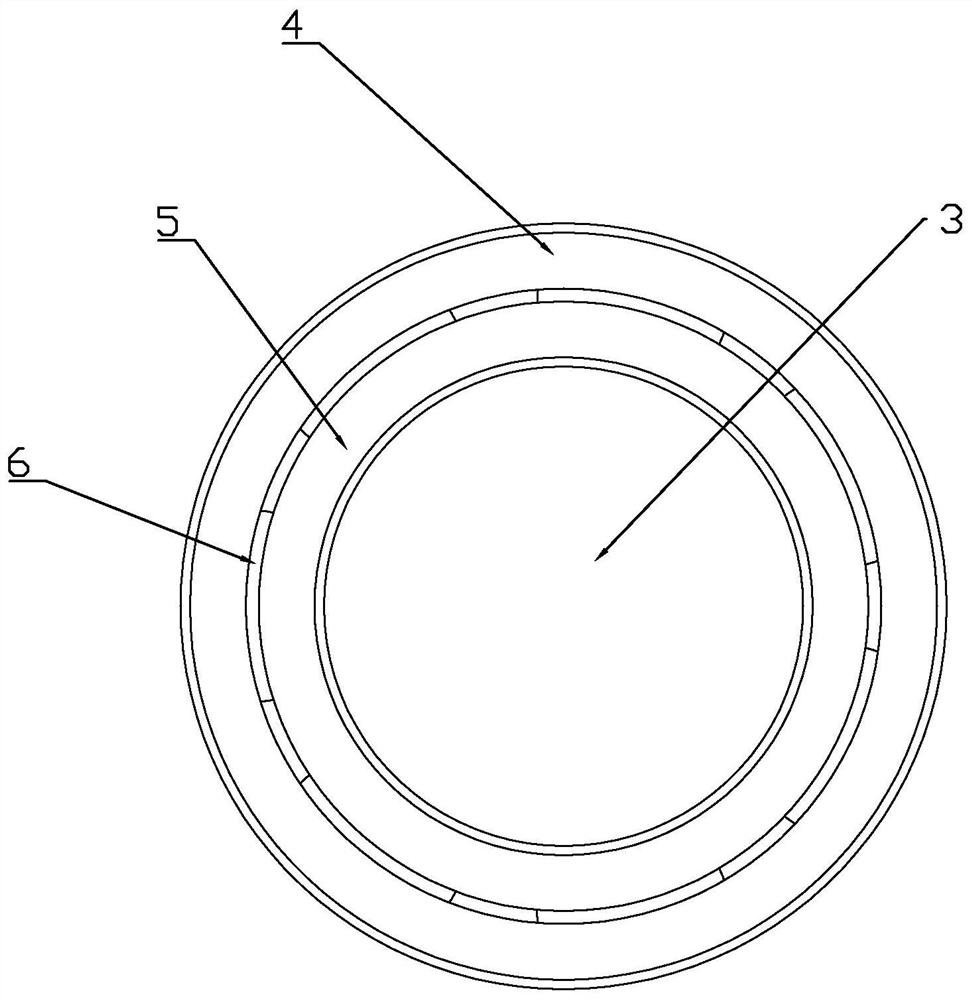

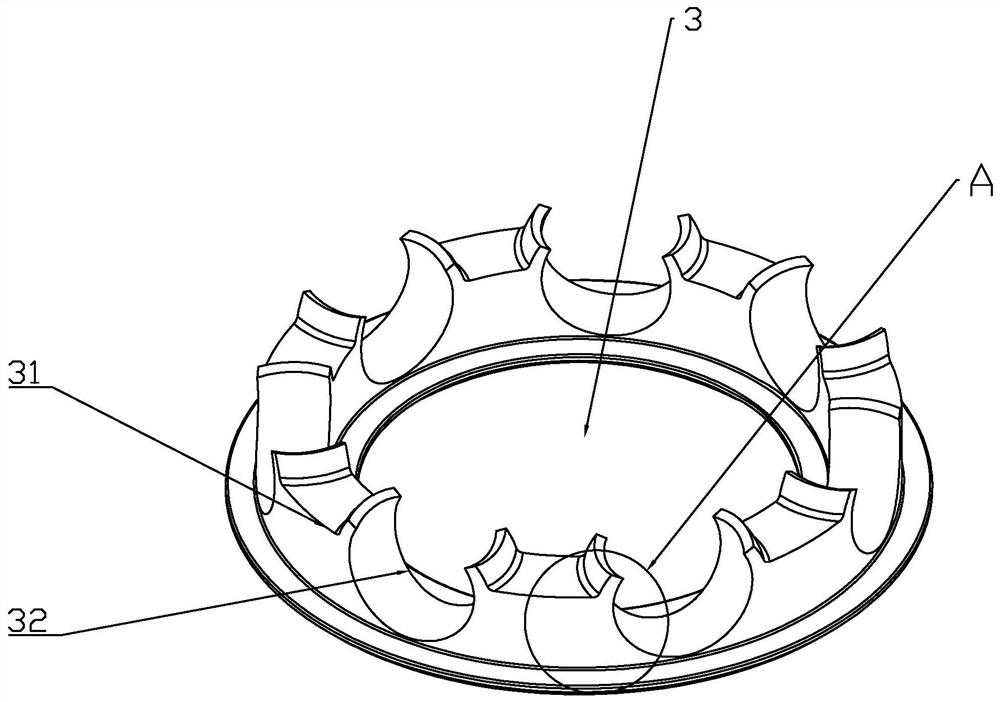

[0018] Depend on Figure 1 to Figure 5 It can be seen that the present invention discloses that the present invention provides a ball bearing, including an outer ring 1 and an inner ring 2, and a flow blocking cage 3 and a row of steel balls 4 are arranged between the inner ring 2 and the outer ring 1, The flow-blocking cage 3 includes a cage body 31 and several pockets 32 evenly opened on the cage body 31, the steel balls 4 are installed in the pockets 32, and the inner diameter and outer diameter of the cage body 31 are Diameters are respectively provided with a first retaining ring 4 and a second retaining ring 5, an oil collection groove 6 for collecting oil is formed between the first retaining ring 4 and the second retaining ring 5, and the inside of the pocket hole 32 is also provided An oil storage assembly 7 for further storing lubricating oil. The beneficial effect of such setting is: adopting the above scheme, setting the first retaining ring 4 and the second retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com