A vortex chamber inlet structure of a swirling flood discharge tunnel for improving water flow

A technology of flood discharge tunnels and vortex chambers, which is applied in water conservancy projects, hydroelectric power generation, hydropower stations, etc., can solve the problems of insufficient energy dissipation in the downstream, large rise height of vortex chamber water flow, etc., to reduce water surface climbing and improve water flow state, the effect of reducing the height difference of the water surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

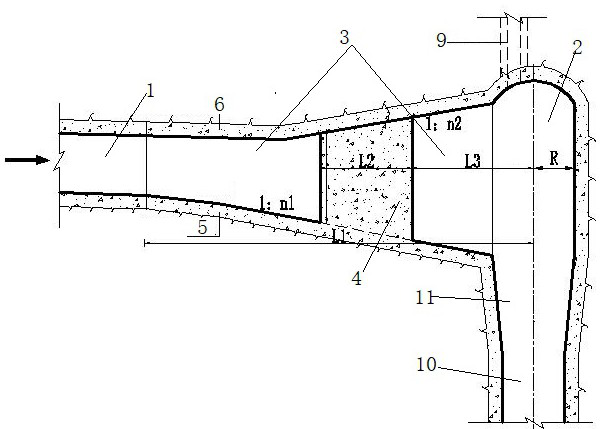

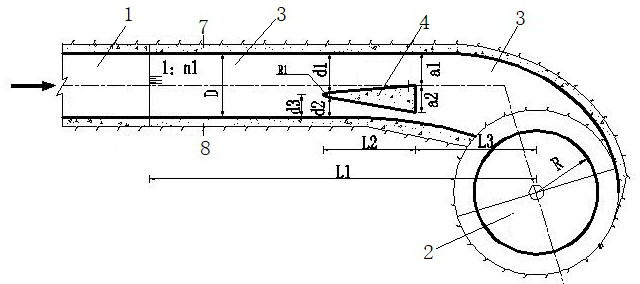

[0021] In order to overcome the problems that the existing water flow is complicated, the water flow in the vortex chamber has a large rising height, and the downstream energy dissipation is insufficient, the present invention provides such as Figure 1-2 As shown in the vortex chamber inlet structure of the swirl flood discharge tunnel for improving the water flow state, the invention reduces the height of the vortex chamber, ensures the safe operation of the flood discharge tunnel with high head and large flow, and is convenient for construction.

[0022] A vortex chamber inlet structure of a swirling flood discharge tunnel for improving water flow state, comprising a water diversion tunnel 1 and a vortex chamber 2, a transition section 3 and a water dividing wall 4, and the transition section 3 is from the diversion tunnel 1 to the vortex chamber. 2, the water dividing wall 4 is arranged on the transition section 3.

[0023] In the present invention, the transition section ...

Embodiment 2

[0026] Based on Embodiment 1, in this embodiment, preferably, the transition section 3 is composed of a bottom plate 5 , a side wall 7 , a side wall 2 8 and a top arch 6 . The second wall 8 is vertically arranged between the bottom plate 5 and the top arch 6, the bottom plate 5 is inclined, the side wall 7 is arranged on the side away from the vortex chamber 2, and the side wall 2 8 is arranged near the vortex chamber 2. side wall, the height of which is transitioned from the side wall of the diversion tunnel 1 to the wall height of the vortex chamber 2; The arc segments are connected with the side wall of the vortex chamber 2 . The section of the transition section 3 is horseshoe-shaped.

[0027] Preferably, the position of the bottom plate 5 in the water diversion tunnel 1 is higher than the position in the vortex chamber 2 .

[0028] Preferably, the slope ratio of the bottom plate 5 is 1:n1, n1 is 1~10, the distance between the starting point of the slope and the center l...

Embodiment 3

[0037] On the basis of Embodiment 1 or 2, in this embodiment, preferably, the thickness of the side wall 17 is 50cm; the width D of the bottom plate 5 is 700cm, the slope ratio of the bottom plate 5 is 1:5.7, and the slope ratio of the slope section of the top arch 6 is 1:3.5, the radius R of the vortex chamber 2 is 675cm, the distance a1 between the backwater surface and the side wall 7 of the transition section 3 is 350cm, the width a2 of the backwater surface is 300cm, the arc radius R1 of the waterfront surface is 150cm, and the sidewalls 1 and 7 of the waterfront surface are The distance between the first wall 7 is d1 is 430cm, the distance d2 between the side wall 2 and the side wall 2 8 is 220cm, the distance between the central axis of the upstream surface and the side wall 2 8 is d3 is 230 cm, the bottom plate 5 The distance between the slope point and the center line of the vortex chamber 2 is L1 is 4220cm, the length L2 of the water dividing wall 4 along the water fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com