Fabricated external wall panel hoisting device for building construction

A kind of building construction and assembly technology, which is applied in the direction of construction, building structure, and building material processing, etc., to achieve the effect of easy and fast construction and convenient and stable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

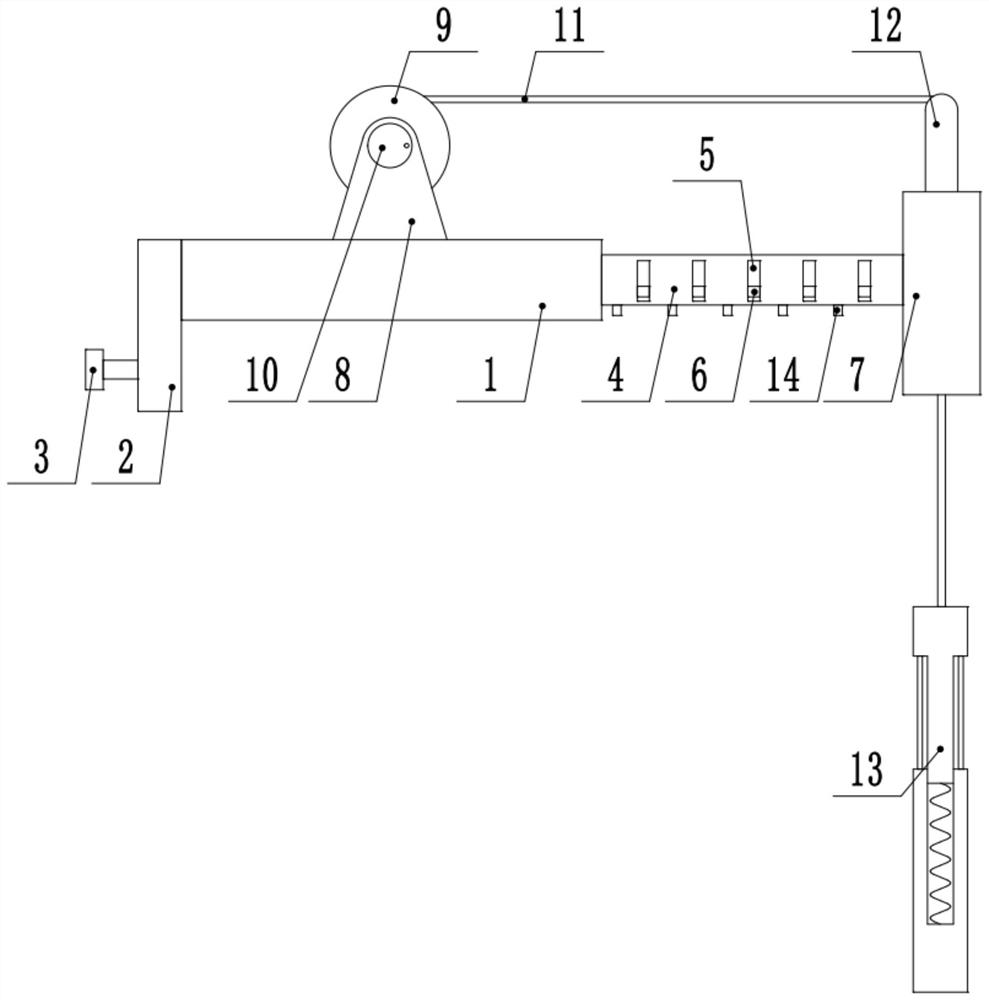

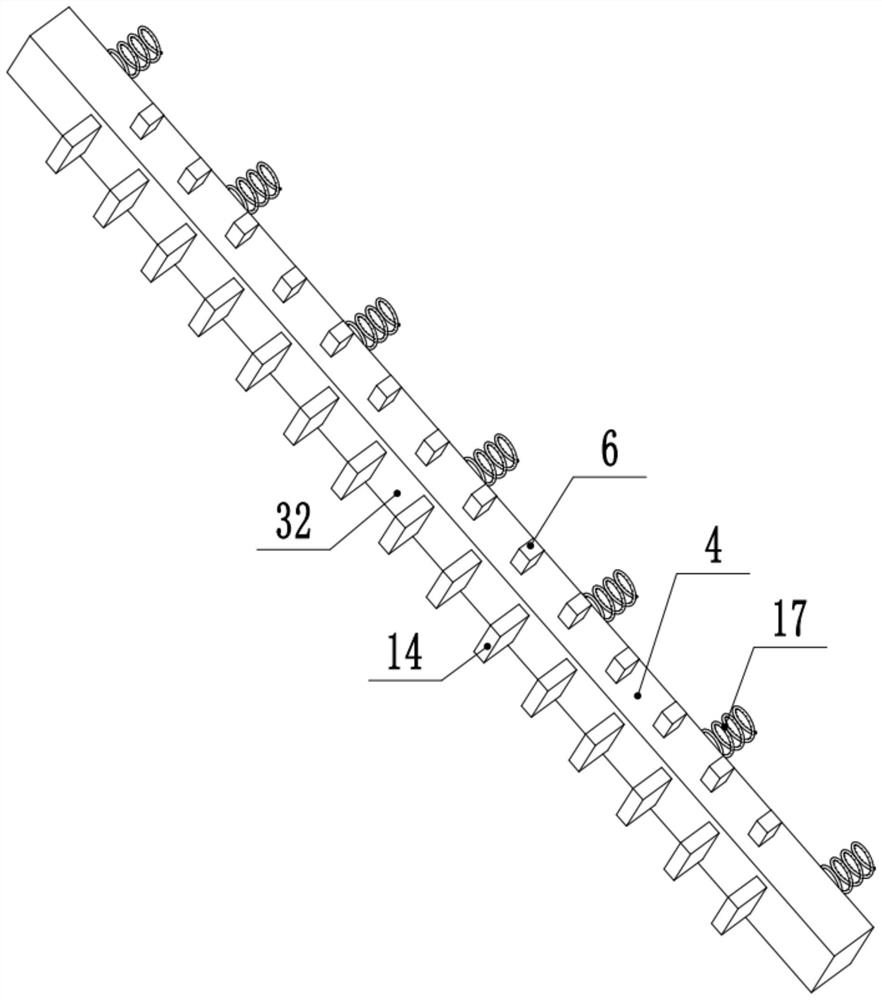

[0028] see Figure 1-6 , an exterior wall panel hoisting device for prefabricated building construction, comprising a top base 1, one end of the top base 1 is provided with an end plate 2, the end plate 2 is fixedly connected with the top base 1, and a compression bolt 3 is installed on the end plate 2 , the compression bolt 3 is threadedly connected with the end plate 2, the top seat 1 is provided with a telescopic assembly, one end of the telescopic assembly extends to the outside of the top seat 1 and connects to the end block 7, the top seat 1 is provided with a retractable mechanism, and the retractable mechanism Connect the stay cord 11, and the end of the stay cord 11 away from the retractable mechanism is connected to the exterior wall panel fixing device 13; wherein, the telescopic assembly includes a telescopic rod 4, and a positioning mechanism is arranged in the telescopic rod 4; Inside the adjusting rod 32, the adjusting rod 32 is provided with a positioning adjus...

Embodiment 2

[0030] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, the difference is:

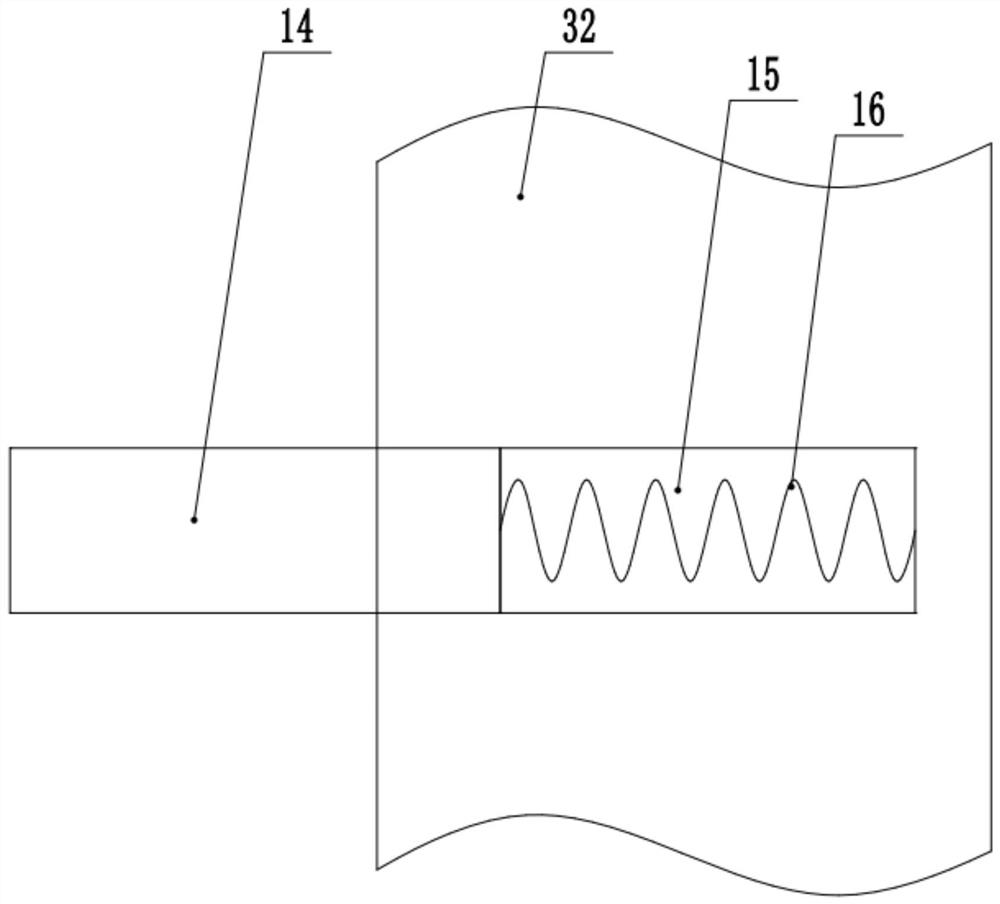

[0031] In one embodiment, the telescopic rod 4 is provided with an adjustment cavity, the adjustment rod 32 is located inside the adjustment cavity, and the positioning adjustment assembly includes a telescopic stopper 14 and a second spring 17 arranged on both sides of the adjustment rod 32, The two ends of the second spring 17 are respectively fixedly connected with the adjustment rod 32 and the telescopic rod 4. The inside of the adjustment rod 32 is provided with an inner groove 15 corresponding to the telescopic stopper 14, and the first spring 16 is fixedly connected in the inner groove 15. A spring 16 is fixedly connected with the telescopic block 14 . The side of the telescopic rod 4 is provided with a retaining groove corresponding to the telescopic stopper 14, and the outside of the adjusting rod 32 is fixedly connected with a plurality of push blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com