Rubber antioxidant product grading device and grading method

A rubber anti-aging agent and grading device technology, which is applied in chemical instruments and methods, solid separation, grids, etc., can solve the problems of low screening efficiency, slow moving speed, slow screening speed, etc., to improve screening and grading efficiency, improve Screening efficiency and the effect of increasing product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

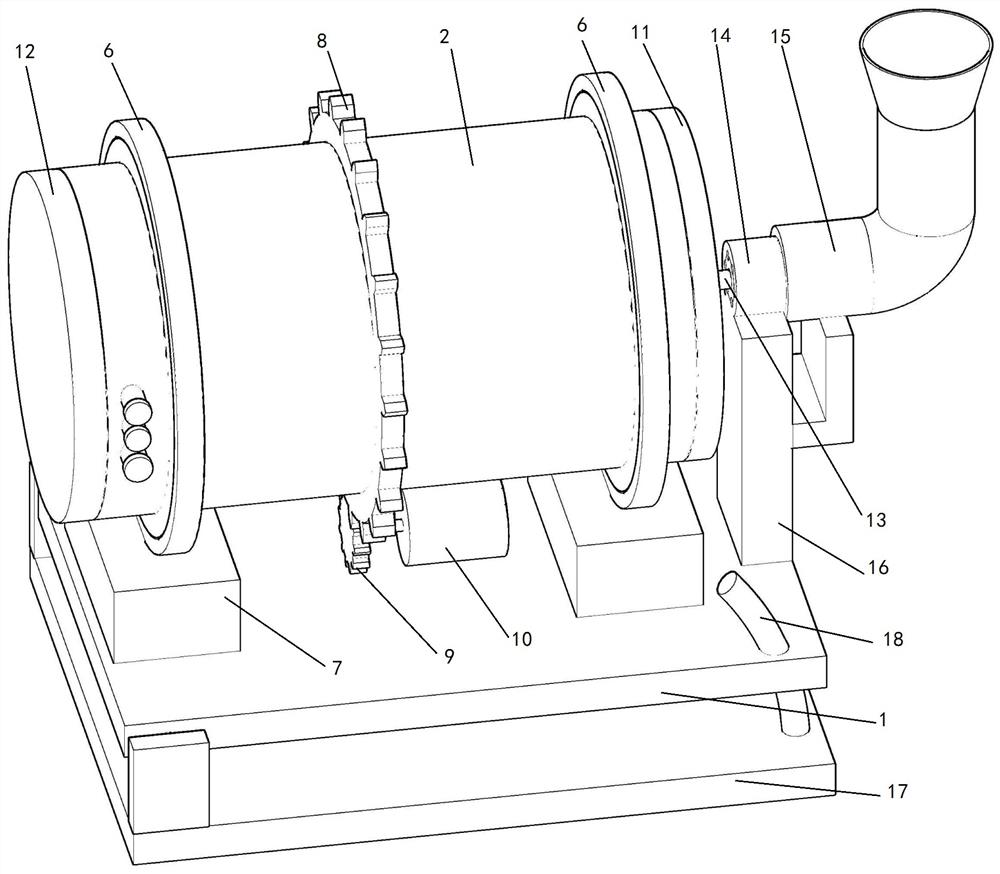

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

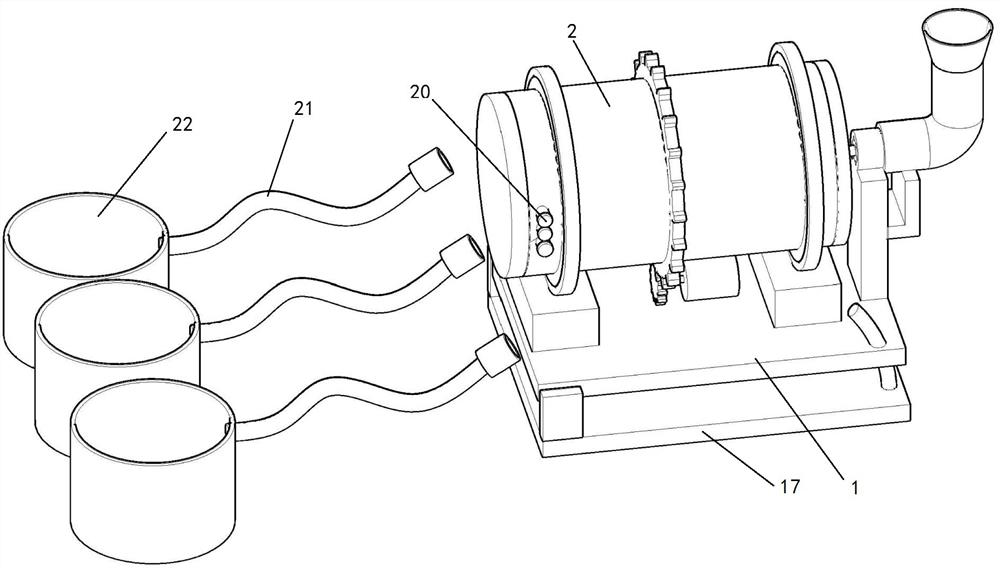

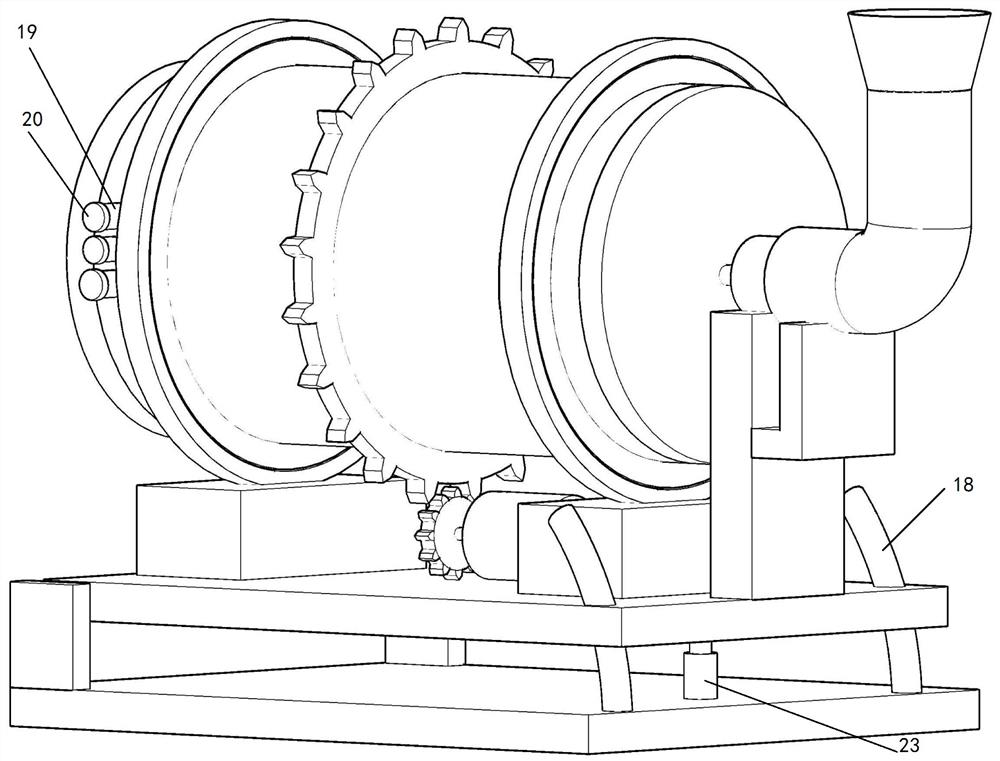

[0025] Such as Figures 1 to 5 As shown, a rubber anti-aging agent product grading device includes a tiltable platform 1, and a rotatable drum 2 is arranged on the tiltable platform 1, and multiple layers of cuboids nested together are sequentially arranged in the drum 2. Sieve 3.

[0026] Preferably, the drum 2 and the plurality of cuboid screens 3 are fixedly connected to each other through a bracket 4 . The drum 2 and the rectangular parallelepiped sieve 3, and the plurality of rectangular parallelepiped sieves 3 are connected to each other as a whole through the bracket 4, and can rotate synchronously.

[0027] Preferably, the front and rear ends of the rectangular parallelepiped sieve 3 are open, and the four sides are evenly provided with a plurality of mesh holes 5, and the mesh holes 5 of the rectangular parallelepiped mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com