Litchi sieving and grading machine and litchi sieving and grading method

A grading machine and lychee technology, applied in grading, chemical instruments and methods, solid separation, etc., can solve problems such as inability to ensure consistent lychee sizes, unsuitable lychee grading, mixed lychee sizes, etc., to improve screening and grading efficiency, screening and grading The effect of high precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

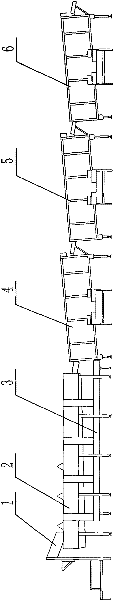

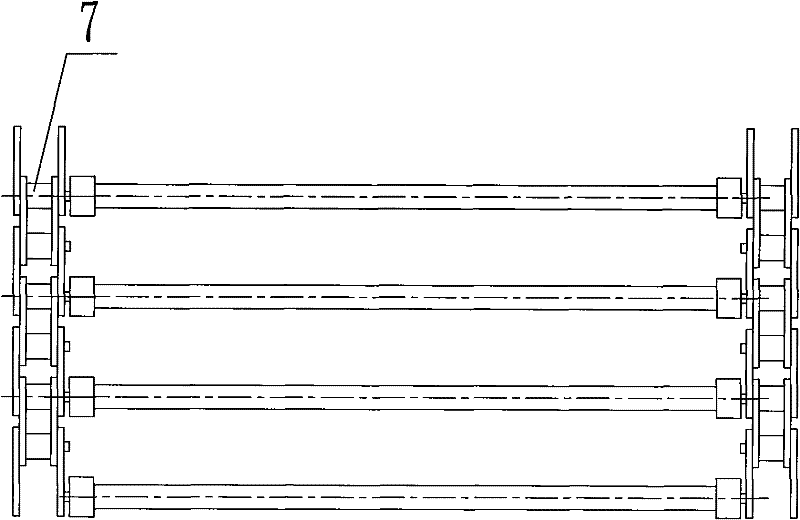

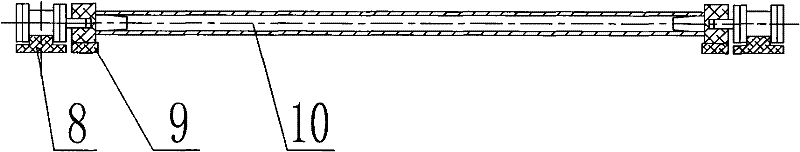

[0016] The litchi screening and grading machine is composed of a mesh belt conveying section and a size grading section, and the mesh belt conveying section is connected with the size grading section. The mesh belt conveying section is equipped with a fence-type fruit unloading trough 1, a mesh belt conveyor 2, and a defective fruit conveyor 3. The fence-type fruit unloading trough 1 is connected to the mesh belt conveyor 2, and the defective fruit conveyor 3 is set on the mesh belt conveyor. 2, the fence-type fruit unloading trough 1 is equipped with a grid for filtering small debris, the mesh belt conveyor 2 is equipped with a paving device and a spray cleaning device, and both sides of the mesh belt conveyor 2 are equipped with rotten fruit. Hole, rotten fruit delivery hole leads to defective fruit conveyor 3. The size grading section is equipped with 4, 5, and 6 sets of size grading machines, and can also be set up as two, four, or five sets of size grading machines, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com