Remote fog gun machine automatic control method for waste steel storage

A warehousing and remote technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of fog cannon machine inconvenient high-altitude dust reduction, etc., to improve the quality and effect of dust reduction, increase or decrease spray time, flexible and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

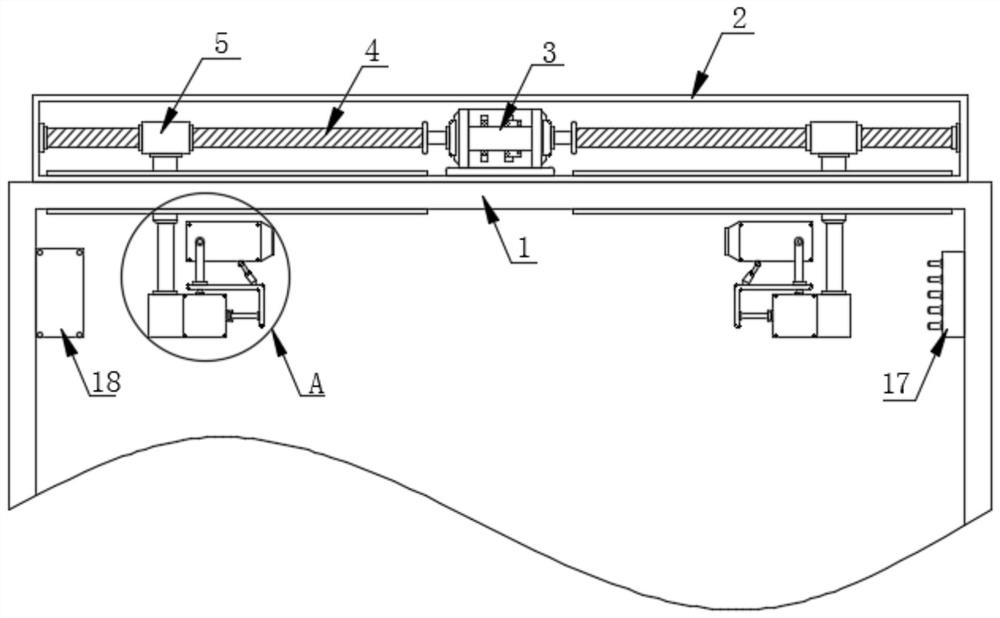

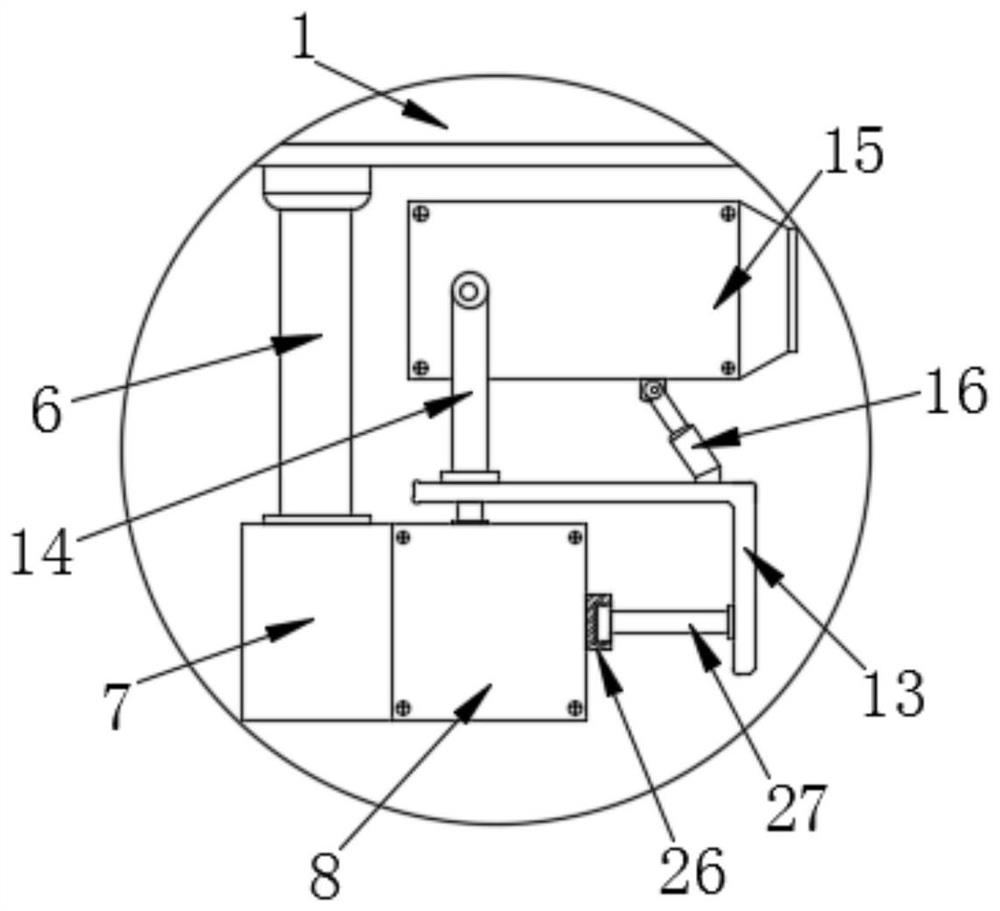

[0040] Such as Figure 1-Figure 6 As shown, a remote fog cannon automatic control method for scrap steel storage in this embodiment adopts a remote fog cannon system for scrap steel storage. Specifically, the fog cannon system includes a storage room 1 and a drive box 2; the drive box 2 Set on the top of the storage room 1, the drive box 2 is provided with a horizontal displacement adjustment assembly, the bottom of the horizontal displacement adjustment assembly is connected with the first electric telescopic rod 6, and the bottom of the first electric telescopic rod 6 is provided with a moving box 8; the moving box 8 A front and rear displacement adjustment assembly is arranged inside, and the end of the front and rear displacement adjustment assembly is connected with the gun fog machine 15, one end of the gun fog machine 15 is hinged with the end of the front and rear displacement adjustment assembly, and the other end is connected with the second electric telescopic rod 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com