A flexible joint and flexible nozzle for wide temperature use

A flexible joint and flexible nozzle technology, which is applied in the directions of jet propulsion, machine/engine, rocket engine, etc., can solve the problem that the structural rigidity and force transmission function of the flexible joint cannot be satisfied, and the use requirements of solid rocket motors can no longer be met. It can not well meet the problems of shear stress and bending moment, so as to achieve the effect of not easy crack propagation damage, improving work stability and reducing negative quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present application will be clearly and completely described below in conjunction with specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present application, rather than all the embodiments. Based on the embodiments of the present application, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present application.

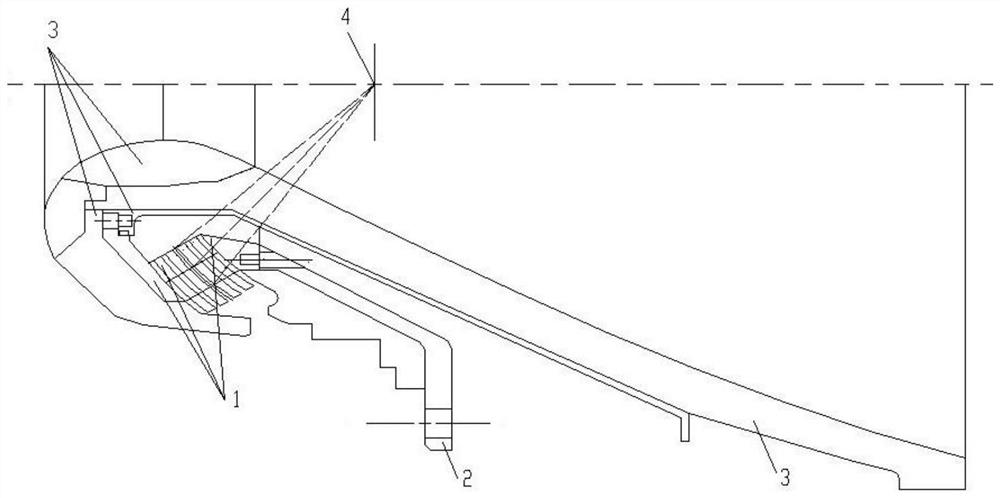

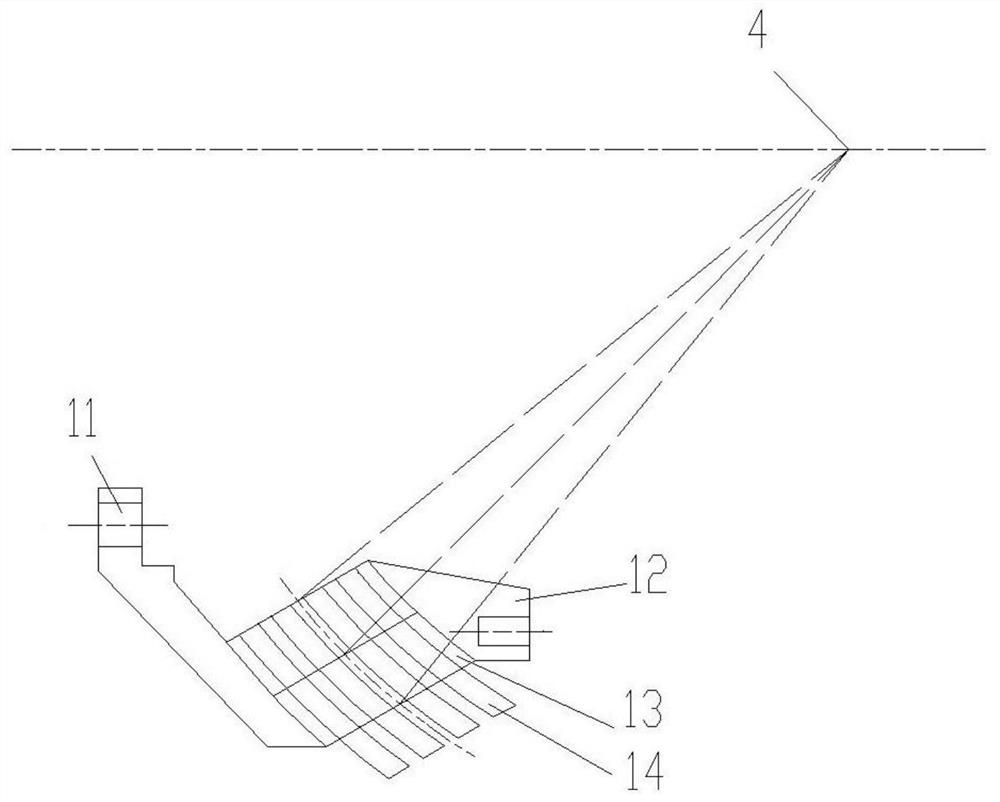

[0031] Such as figure 1 As shown, the application discloses an embodiment of a flexible joint for wide temperature use, including a front flange 12, a rear flange 11, a multi-layer elastic member 13 and a multi-layer reinforcement 14, the front flange 12 and the rear flange 11 They are connected by multi-layer elastic parts 13 and multi-layer reinforcement parts 14 .

[0032]The elastic part 13 is made of a special addition-type liquid silicone rubber material with excellent low-temperature pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com