Integrated ball valve element plug valve and assembling method

A technology for plug valves and ball valves, applied in the field of integrated ball valve core plug valves and assembly, which can solve the problems of scattered parts, complex structure, unfavorable site management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

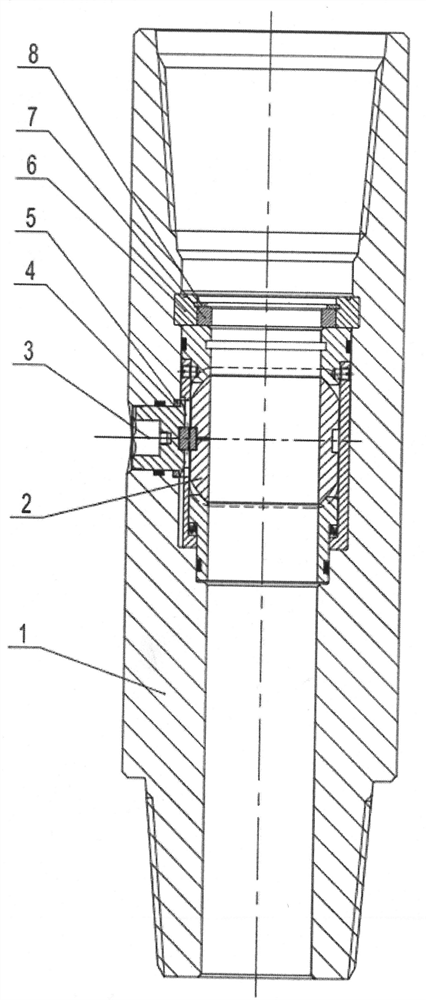

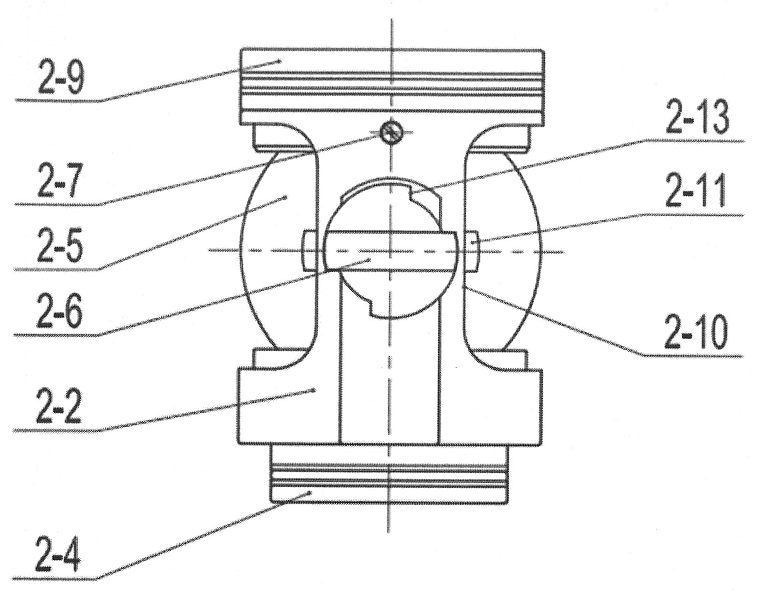

[0033] Please refer to figure 1 This embodiment provides an integrated balloon plug valve and assembly method comprising a 1-valve body, a 3-operation key, 3-operation key, and 1-valve body fitting, 1-valve body 5-sealed gasket set between steps, 1-integrated ball valve, 6-set, 7-support sleeve, and 8-hole, 2-integrated ball valve core; 2-integrated ball valve core - Mounting tube, 2-3-wave spring, 2-4-, 2-5-ball, 2-6-convex bond and 2-9-upper club composition; 2-2-mounting tube down part The surface of the stepped holes and 2-4-lower outer circumstances are formed with 2-3-wave spring, 2-2-mounting tubes, 2-6-convex keys and 2-5- The core, the upper inner hole of the 2-2-mounting tube is set on the lower outer step of 2-9- upper club, and the screw is fixedly connected by the 2-7-cylindrical end slot; 1-valve body inner wall Setting 4-Seal 1 between the 3-Operation Key; 1-Valve body and 2-4-, 2-1-sealing rings 2 and 2-8, respectively, and 2-9-upper spherical seats. - Sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com