Three-planet-row hybrid power driving device

A driving device and hybrid power technology, applied in the field of new energy vehicles, can solve the problems of high control difficulty, lack of success in hybrid hybrid power system, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

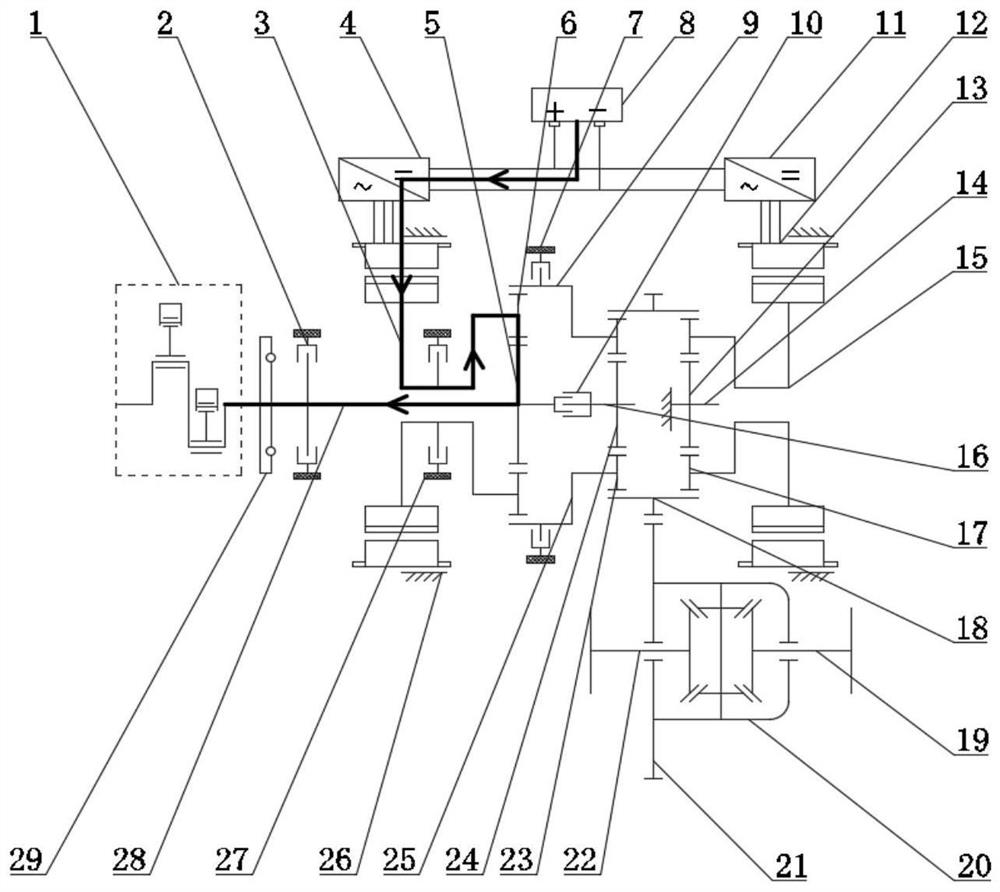

[0068] Engine quick start mode:

[0069] Such as figure 2 As shown, the clutch 10 is in the disengaged state, the third brake 7 is in the braking state, and the first brake 2 and the second brake 27 are not braking. The first motor 26 obtains electric energy from the power battery 8 to generate power and transmits the power to the first planetary carrier 3, and the first planetary carrier 3 transmits the power to the first sun gear 5 through the first planetary gear 6, and the first sun gear 5 will The power is transmitted to the engine 1 through the torsional shock absorber 29 to the optimum starting speed, so as to realize the fast starting mode of the engine.

Embodiment 2

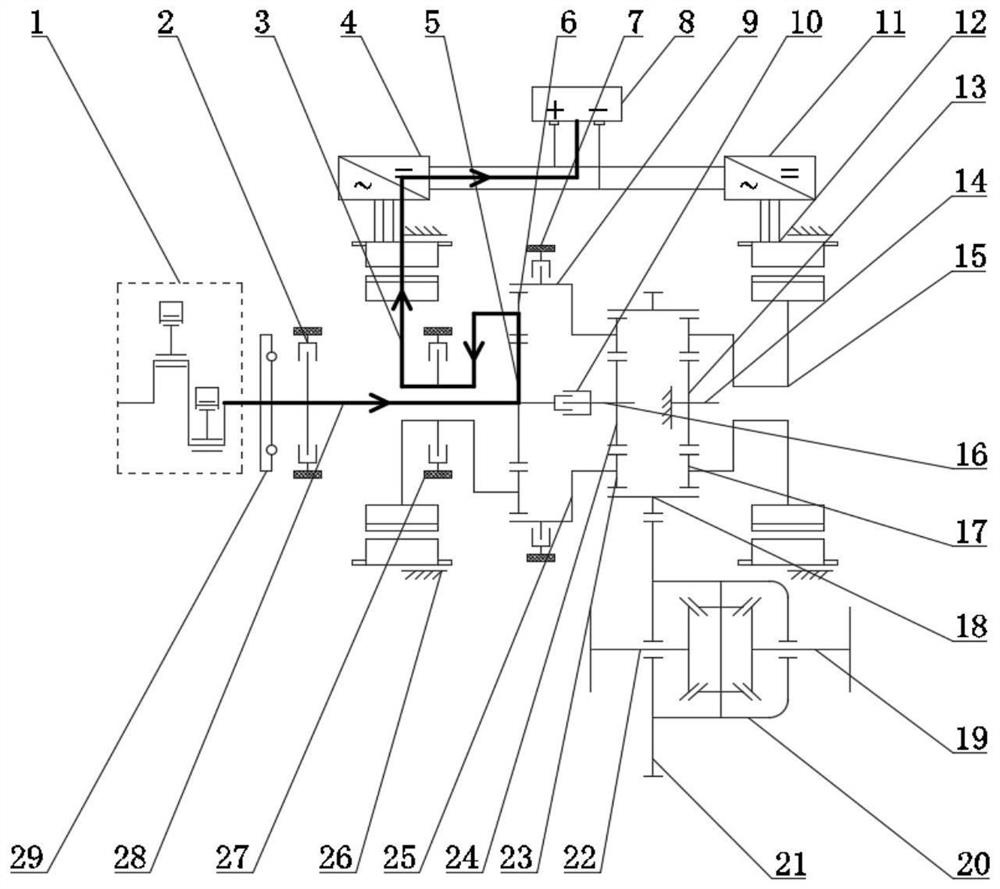

[0071] Parking power generation mode:

[0072] Such as image 3 As shown, the clutch 10 is in the disengaged state, the third brake 7 is in the braking state, and the first brake 2 and the second brake 27 are not braking. The engine 1 transmits the power to the first sun gear 5 through the first sun gear shaft 28 through the torsional shock absorber 29, and the first sun gear 5 transmits the power to the first planet carrier 3 through the first planetary gear 6, and the first planet carrier 3 The power is transmitted to the first electric motor 26, and the first electric motor 26 converts the power into electric energy and stores it in the power battery 8 to realize the parking power generation mode.

Embodiment 3

[0074] Level 1 pure electric drive mode:

[0075] Such as Figure 4 As shown, when the whole vehicle is in a medium-speed and medium-power driving condition, the clutch 10 is in a disengaged state, the first brake 2, the second brake 27, and the third brake 7 do not brake, and the engine 1 and the first motor 26 are turned off. state. The second motor 12 obtains electric energy from the power battery 8 to generate power and transmits the power to the third planetary carrier 15, and the third planetary carrier 15 transmits the power to the second ring gear 18 through the third planetary gear 17, and the second ring gear 18 will The power is transmitted to the differential gear 21, and the differential gear 21 transmits the power to the left half-shaft 22 and the right half-shaft 19 through the differential gear assembly 20, realizing the first-level pure electric drive mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com