Power cable withstand voltage test detection equipment

A technology of withstand voltage test and detection equipment, applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problem of inability to meet the needs of different types of cable detection, and achieve the effect of changing the radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

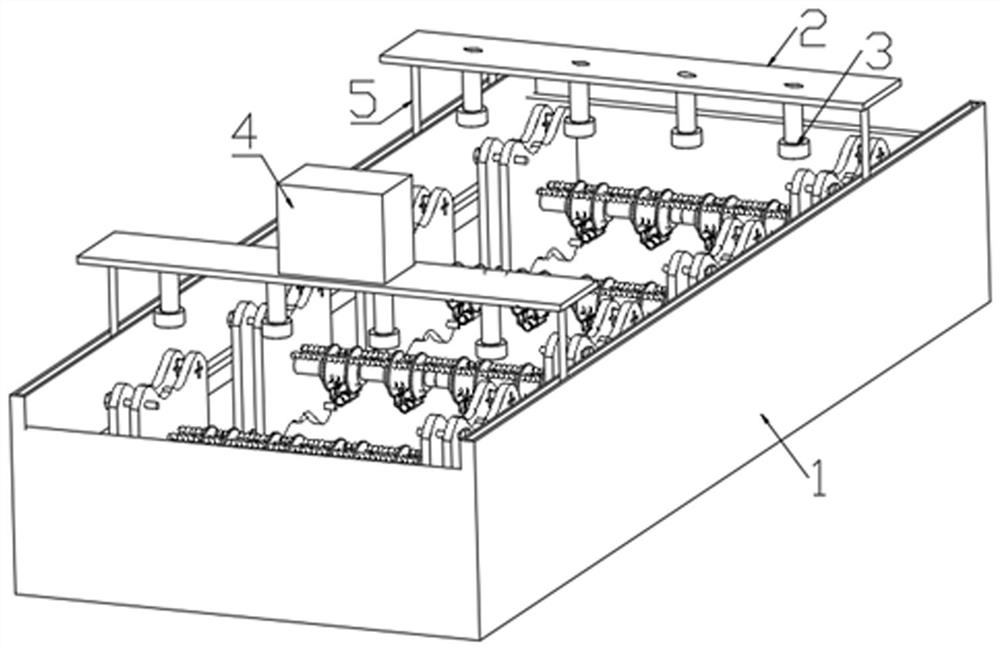

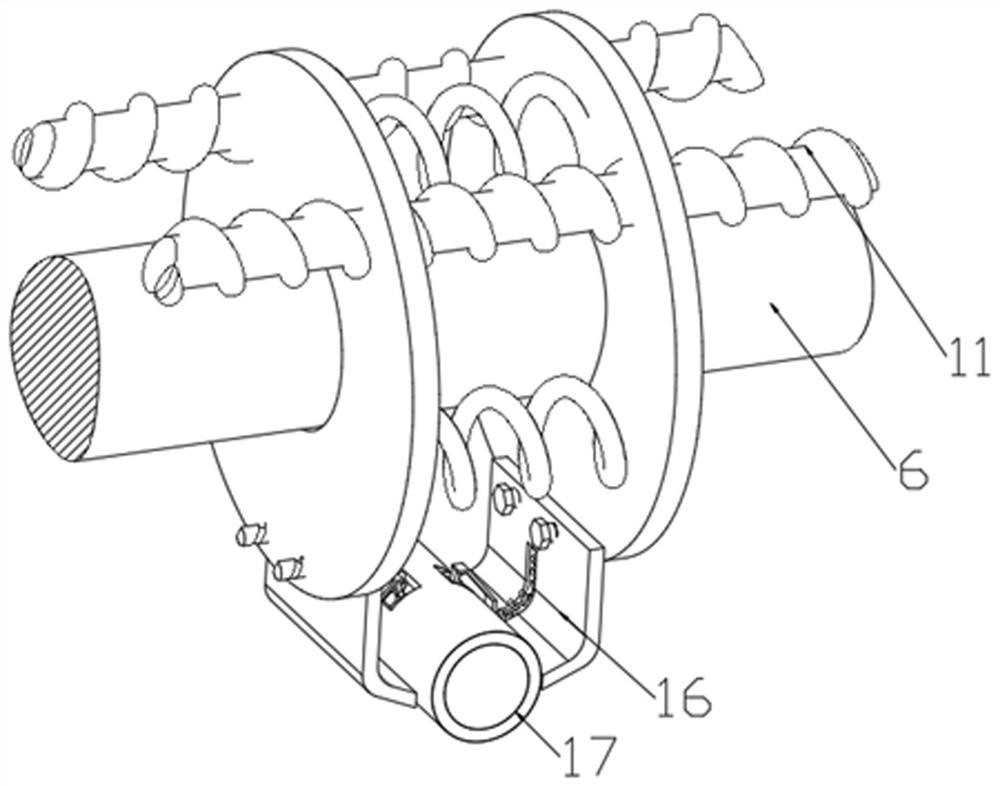

[0025] see Figure 1-4 , in an embodiment of the present invention, a power cable withstand voltage test and detection equipment mainly includes a heat preservation room 1 .

[0026] The heat preservation chamber 1 is provided with a constant temperature tank, and the upper side of the heat preservation chamber 1 is symmetrically provided with a plurality of sliding grooves and a plurality of sliding rods 5 that can be slidably connected with the sliding grooves, and the tops of every two sliding rods 5 are installed There is a top plate 2, and a plurality of through holes are opened on the top plate 2 on the front side, the bottom end of the through holes is connected with a wire barrel, and the other end of the wire barrel is connected with a plug-in wire for clamping the connection port of the test line Connector 3, the upper side of the top plate 2 on the rear side is equipped with a tester 4 for applying current to the test cable, and the output end of the tester 4 is als...

Embodiment 2

[0029] see Figure 1-4 , in an embodiment of the present invention, a power cable withstand voltage test and detection equipment mainly includes a heat preservation room 1 .

[0030] The heat preservation chamber 1 is provided with a constant temperature tank, and the upper side of the heat preservation chamber 1 is symmetrically provided with a plurality of sliding grooves and a plurality of sliding rods 5 that can be slidably connected with the sliding grooves, and the tops of every two sliding rods 5 are installed There is a top plate 2, and a plurality of through holes are opened on the top plate 2 on the front side, the bottom end of the through holes is connected with a wire barrel, and the other end of the wire barrel is connected with a plug-in wire for clamping the connection port of the test line Connector 3, the upper side of the top plate 2 on the rear side is equipped with a tester 4 for applying current to the test cable, and the output end of the tester 4 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com