Bearing testing machine

A testing machine and bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of complex process and high cost of large-scale equipment, and achieve the effect of improving performance, ingenious and simple design, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

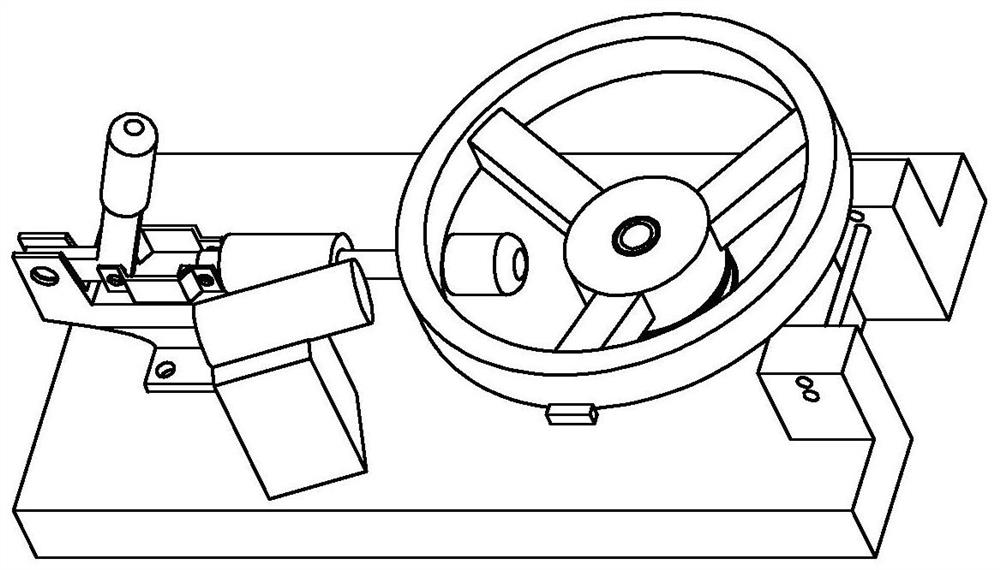

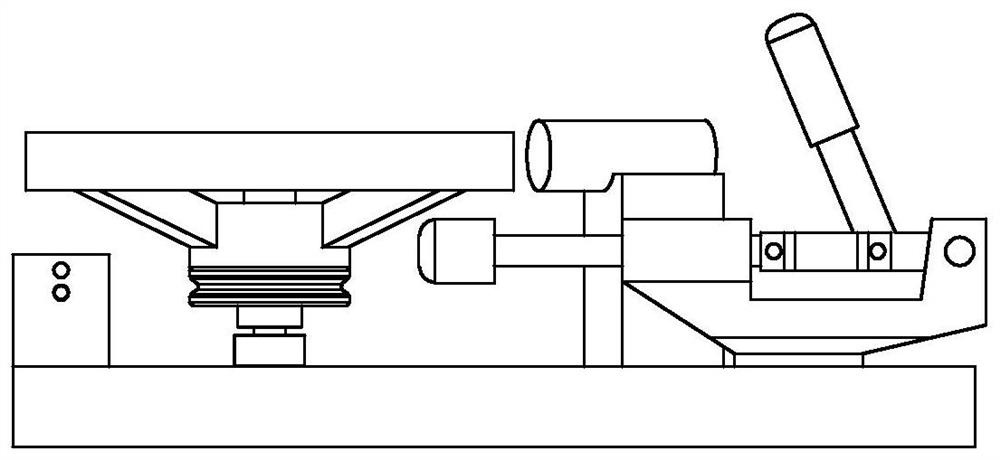

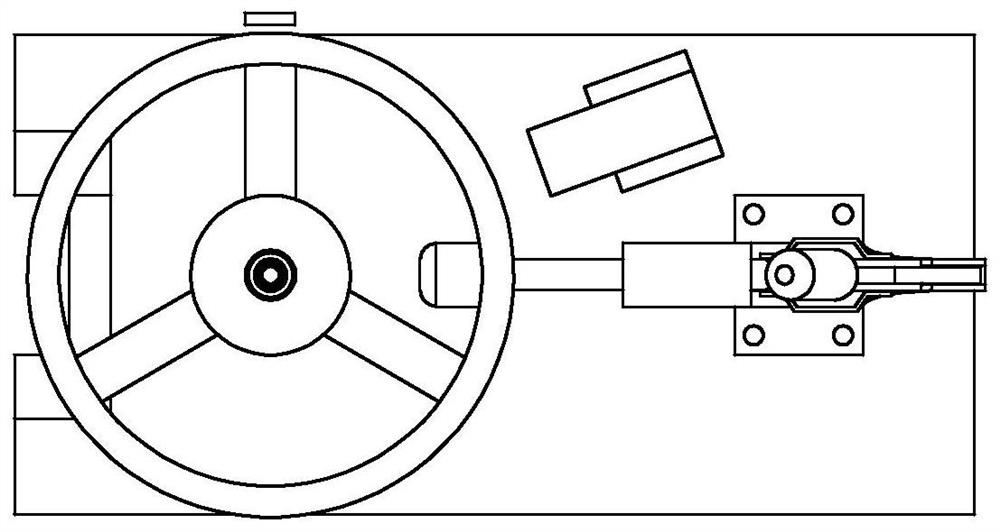

[0013] Such as figure 1 , 2 , The bearing testing machine shown in 3 and 4 includes a worktable 1, a rotating shaft 6 is arranged on the surface of the working table 1, a retaining ring is arranged in the middle of the rotating shaft 6, a rotating body 5 is set on the retaining ring, and a rotating body 5 is arranged on the rotating body 5. Bearing 4 is arranged, and bearing 4 is fixed by rotating disk 2, and rotating disk 2 outer wall is provided with magnet 3, and rotating disk 2 outside is provided with counter 8, and counter 8 is fixed on the mount 7, and counter 8 is connected with display.

[0014] The surface of the workbench 1 is provided with a pull rod seat 9, and the pull rod seat 9 includes a movable rod, the head of the movable rod protrudes, and the protrusion contacts the bearing 4.

[0015] The outer side of the workbench 1 is provided with vertical fixing seats, hollowed out between the fixing seats, and a fixing bar is arranged in the middle of the fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com