A kind of tea cake pressing machine and tea cake production process

A pressing machine and tea cake technology, applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve the problems of low tea cake processing efficiency and complicated process, so as to reduce the operation of dumping tea leaves, improve efficiency, reduce The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

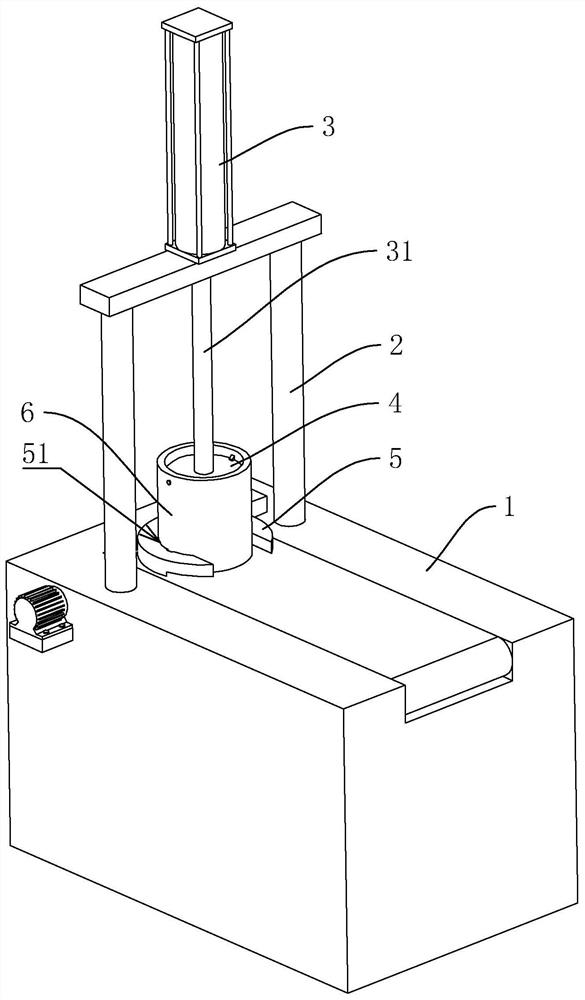

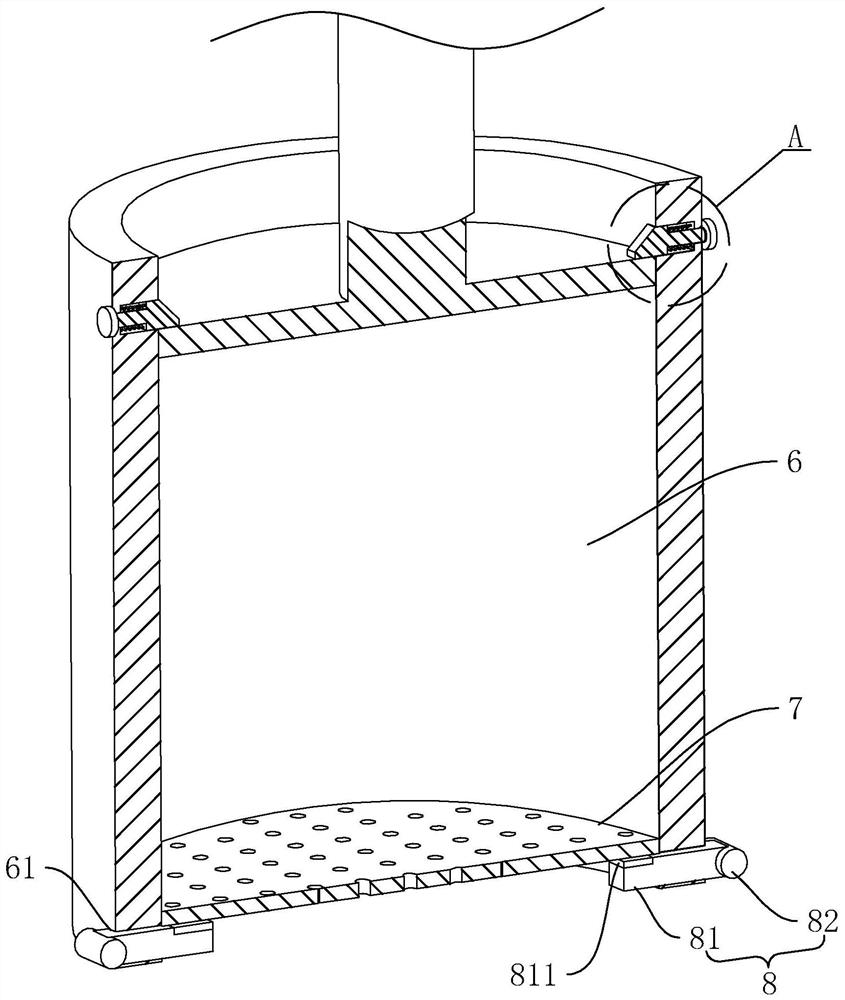

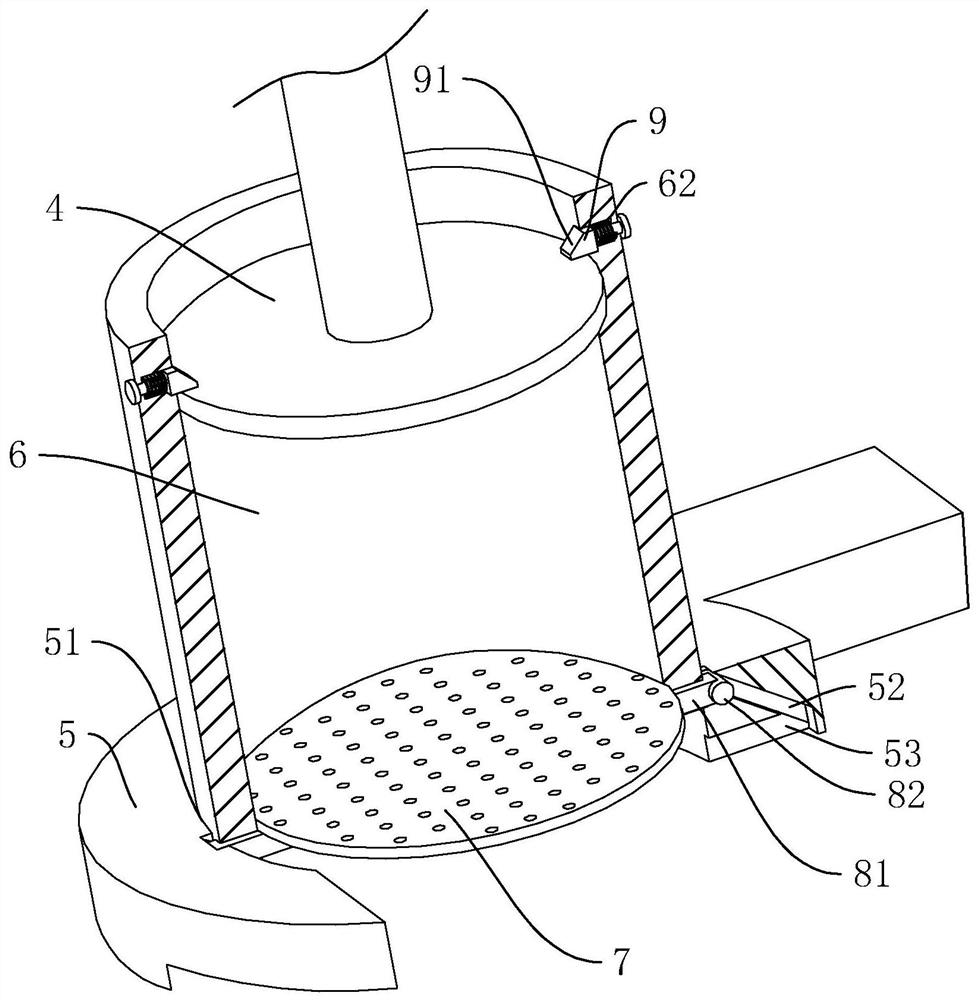

[0040] The embodiment of the present application discloses a tea cake pressing machine and a tea cake production process. refer to figure 1 , The tea cake press machine includes a workbench 1, and the workbench 1 extends upward and is welded with a support frame 2, and the support frame 2 is fixed with a bolt to drive the cylinder 3. The piston rod 31 is in a state of moving toward or away from the worktable 1 . The end of the piston rod 31 facing the workbench 1 is welded with an upper mold 4, and the position coaxial with the upper mold 4 on the workbench 1 is welded with a mounting seat 5, and a steam barrel 6 is plugged inside the mount 5, and the steam barrel 6 is used for Place the tea leaves.

[0041] refer to figure 1 and figure 2 , before carrying out the pressing operation of the tea cake, it is necessary to place the dried loose tea inside the steamer 6, and soften ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com