A pressure sensitive detection circuit, chip, system and pressure sensitive detection method

A detection circuit and detection method technology, applied in the direction of electrical components, electronic switches, pulse technology, etc., to avoid false triggering, improve interactive flexibility, and avoid repeated or missed reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

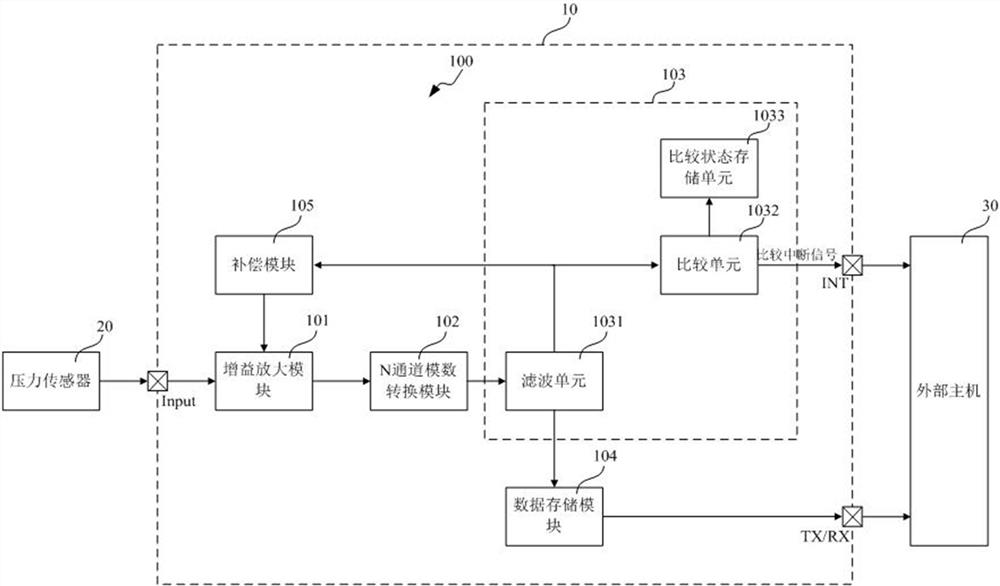

[0046] like figure 1 As shown, this embodiment provides a pressure-sensitive detection circuit, and the pressure-sensitive detection circuit 100 includes:

[0047] N gain amplification modules 101, configured to receive an analog electrical signal output by a corresponding pressure sensor, and perform gain amplification on the analog electrical signal;

[0048] The N-channel analog-to-digital conversion module 102 is correspondingly connected to the output terminals of the N gain amplification modules 101, and is used to sequentially perform analog-to-digital conversion on the amplified signals output by the N gain amplification modules 101;

[0049] The interrupt generating module 103 is connected to the output end of the N-channel analog-to-digital conversion module 102, and is used to perform signal processing on the digital signals sequentially output by the N-channel analog-to-digital conversion module 102 and generate an interrupt signal, and the interrupt signal include...

Embodiment 2

[0067] like image 3 As shown (in the figure, N is equal to 1 as an example), compared with the pressure sensing circuit described in Embodiment 1, the interrupt generation module 103 described in this embodiment includes:

[0068] The filtering unit 1031 is connected to the output end of the N-channel analog-to-digital conversion module 102, and is used for filtering the digital signals sequentially output by the N-channel analog-to-digital conversion module 102 to generate N sets of pressure data;

[0069] The comparing unit 1032 is connected to the output end of the filtering unit 1031, and is used to compare N sets of pressure data with a comparison threshold in turn, and generate a comparison interrupt signal when the pressure data is greater than the comparison threshold.

[0070] Specifically, the comparison unit 1032 is realized by using a comparator; wherein, when N is greater than 1, the comparison unit 1032 can be realized by using only one comparator, or can be rea...

Embodiment 3

[0084] Such as Figure 4 As shown (in the figure, N is equal to 1 as an example), compared with the pressure sensing circuit described in Embodiment 1, the interrupt generation module 103 described in this embodiment includes:

[0085] The filtering unit 1031 is connected to the output end of the N-channel analog-to-digital conversion module 102, and is used for filtering the digital signals sequentially output by the N-channel analog-to-digital conversion module 102 to generate N sets of pressure data, and in the The N channel analog-to-digital conversion module 102 generates an ADC interrupt signal after completing N channel sampling;

[0086] The comparing unit 1032 is connected to the output end of the filtering unit 1031, and is used to compare N sets of pressure data with a comparison threshold in turn, and generate a comparison interrupt signal when the pressure data is greater than the comparison threshold.

[0087] Specifically, the comparison unit 1032 is realized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com