Part collecting device of conveying system

A conveying system and collection technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as affecting work efficiency, collision or bottom friction, damage, etc., to achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: The idea of this embodiment is that when the flow of goods is not much, the collection operation is carried out, that is, the goods on the assembly line are stored in a centralized manner. After reaching a certain amount, they are sent out one after another, so as to form a staged and continuous output of goods. The staff arranges their working hours well.

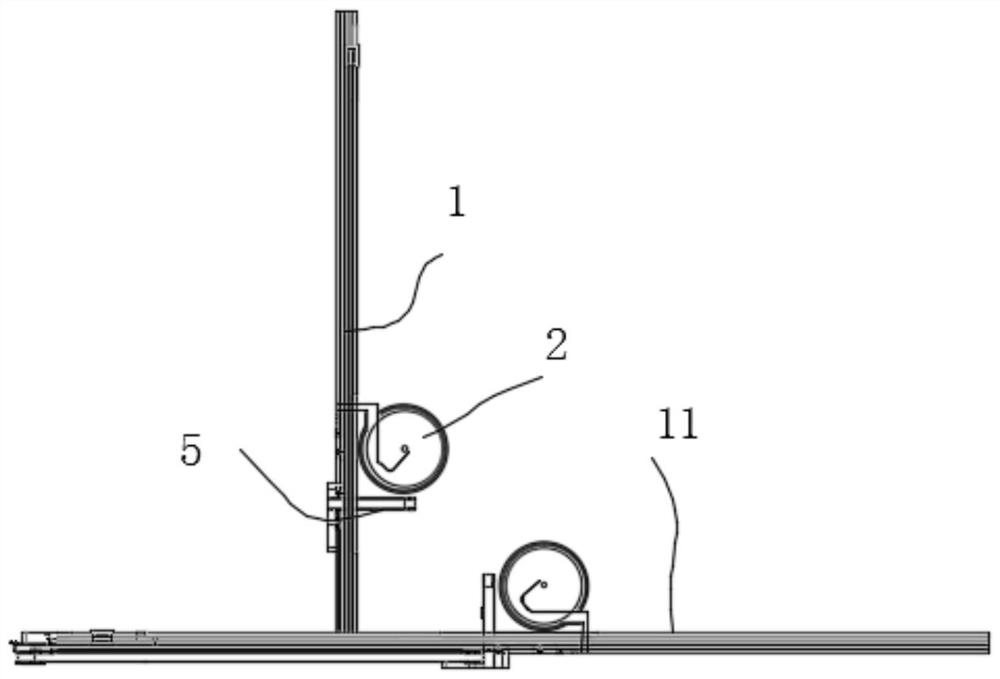

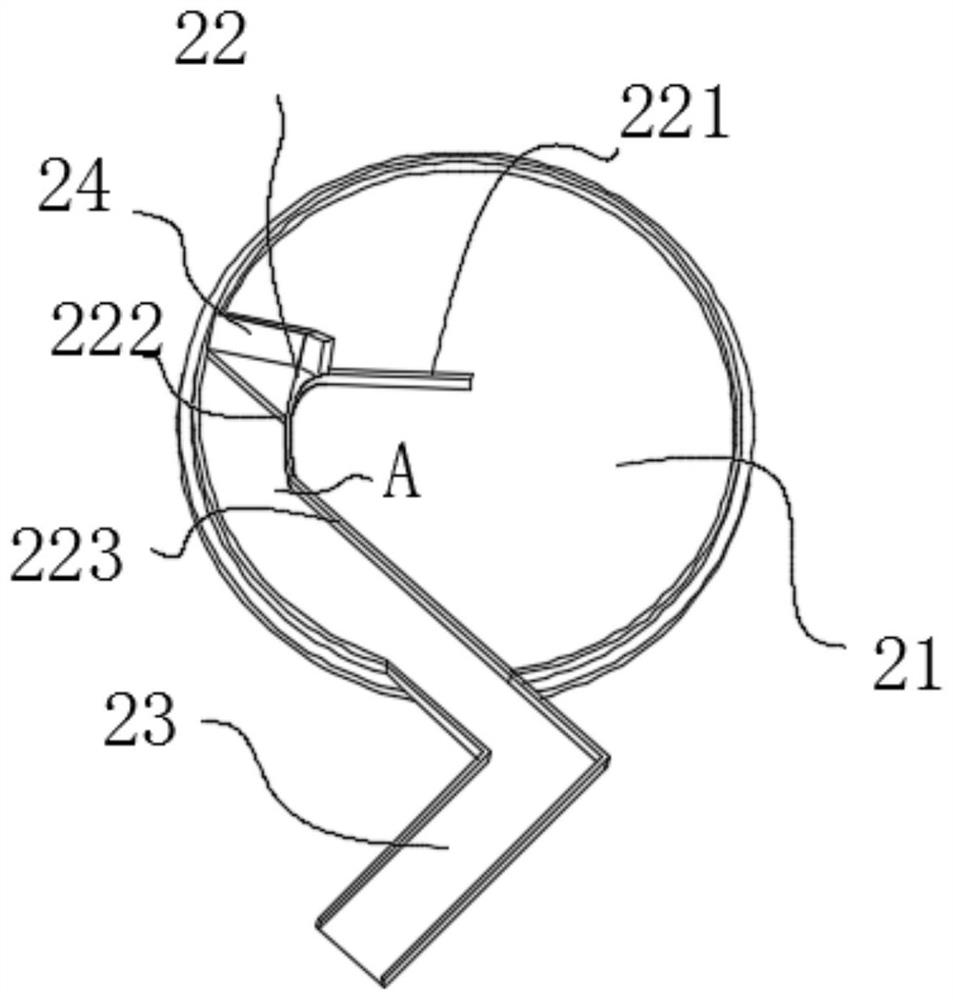

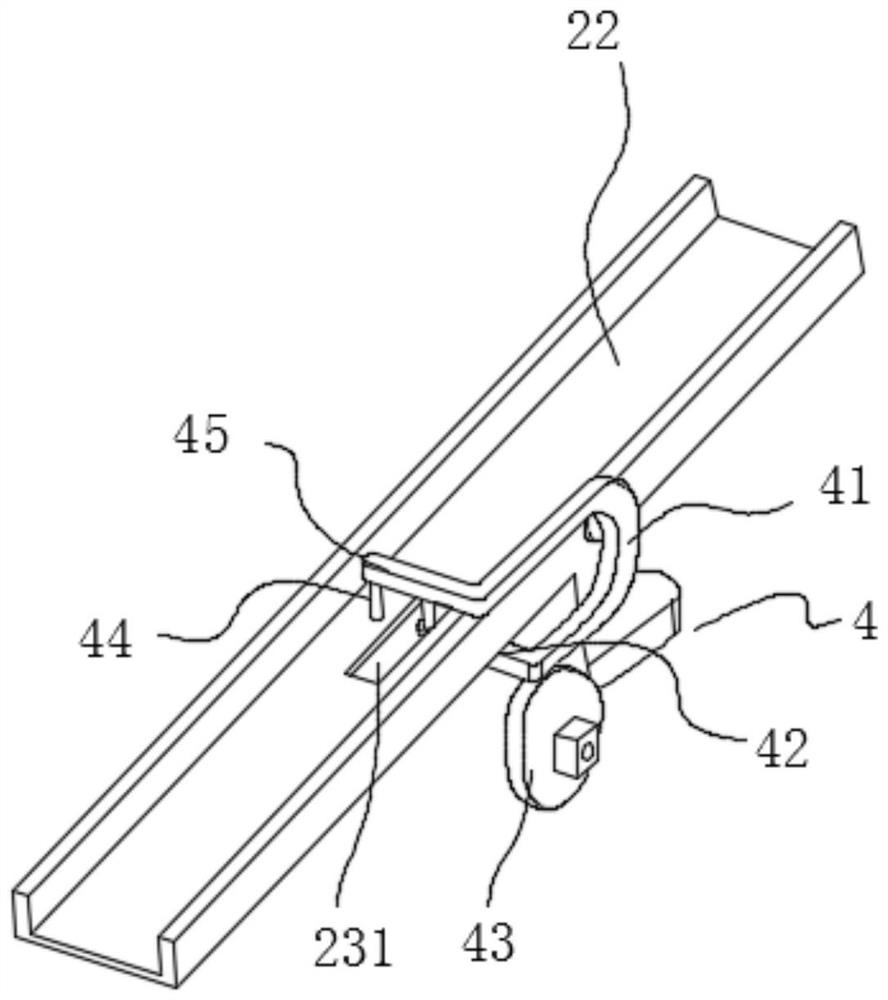

[0020] Specifically: refer to figure 1 As shown, a collection device 2 is set on the assembly line 1 composed of conveyors. When there are few goods on the assembly line, the goods are transferred to the collection device 2 through the steering conveyor 5 for temporary storage. After a certain amount, Then output to the assembly line 1 successively from the assembly device 2 .

[0021] Based on the above ideas, multiple assembly devices 2 can be provided on the assembly line, for example, each branch on the assembly line 11 provided with branches can be provided. Setting a plurality of assembly devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com