Labor-saving thinning stretching method adopting rolling shaft structure

A technology of roller and drawing die, which is applied in the field of metal plastic forming, can solve problems such as cylinder wall tearing, bottom pulling, scratches on the surface of stretched parts, etc., and achieves the advantages of improved service life, novel methods and strong flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

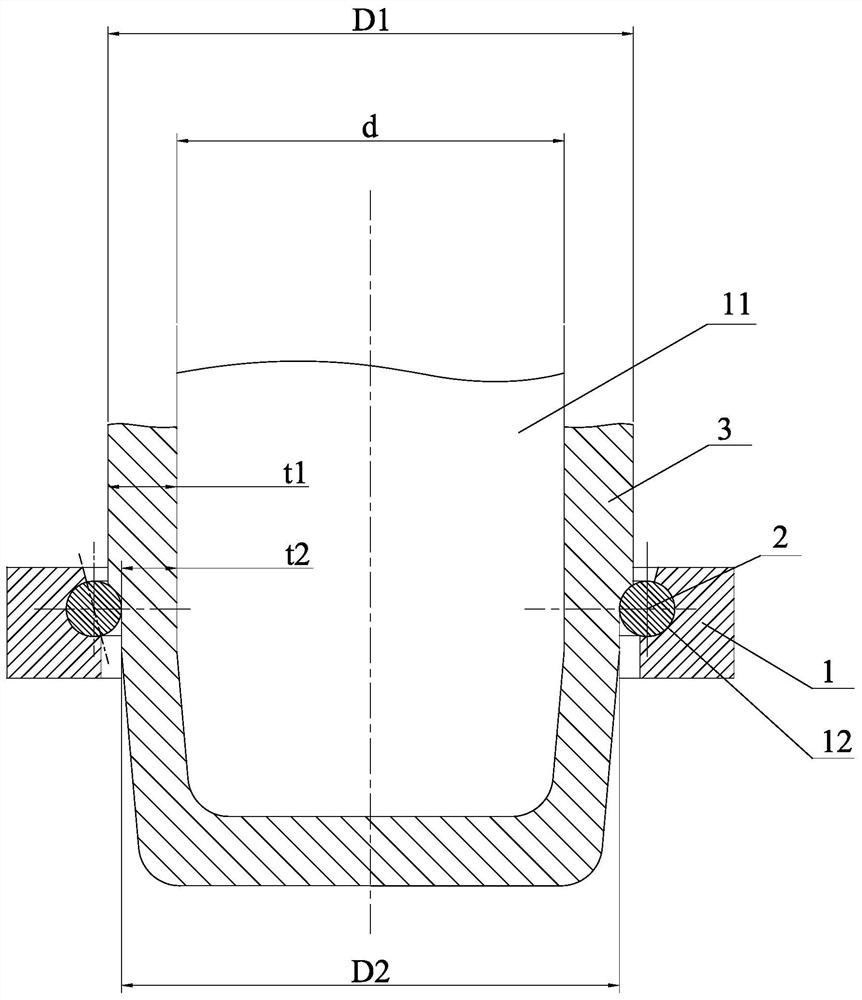

[0016] Taking the cylindrical part as an example, the following combination Figure 1 to Figure 4 And specific embodiment is described in detail the present invention.

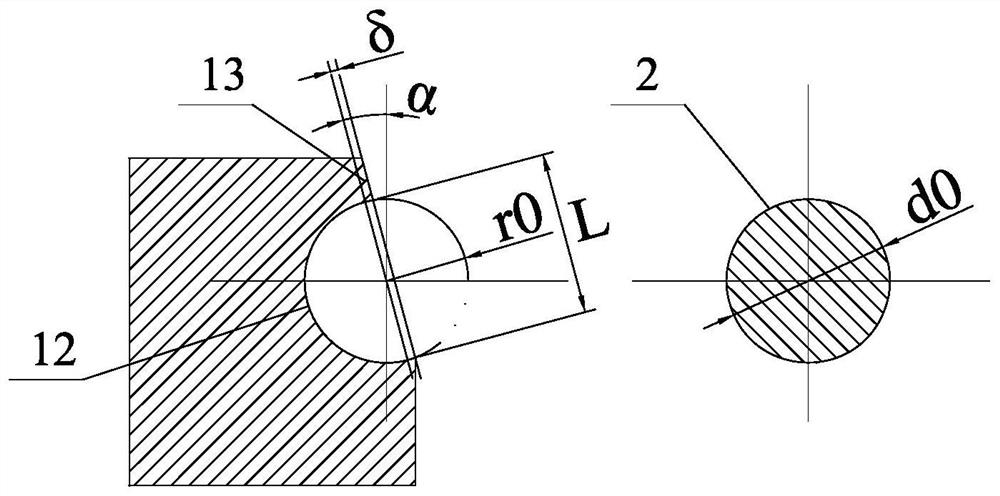

[0017] The invention relates to a labor-saving thinning drawing die adopting a roller structure, such as figure 1 As shown, it includes a drawing die ring 1 and a roller 2. The drawing die ring 1 is annular, and the drawing die ring 1 is provided with a hollow drawing member channel 11 for the drawing member 3 to pass through. A plurality of grooves 12 are provided on the inner wall of the stretching member passage 11, and a rotating cylindrical roller 2 is coaxially embedded in each of the grooves 12;

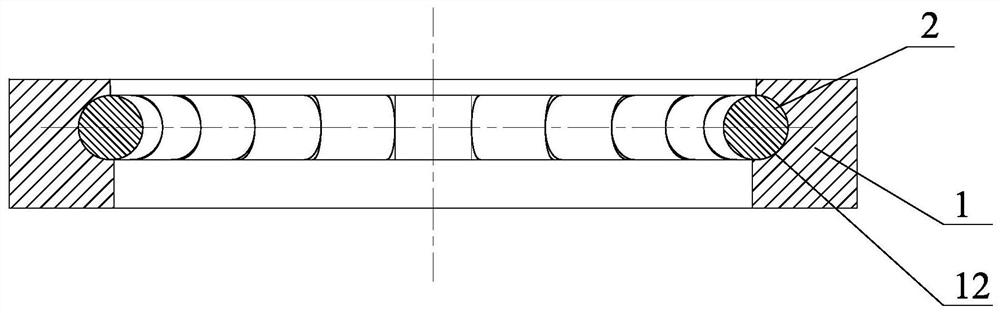

[0018] Such as image 3 As shown, the rotation axis of the roller 2 is perpendicular to the central axis of the drawing die ring 1, and two adjacent rollers 2 are closely abutted against each other, so that all the rollers 2 on the inner wall of the drawing die ring 1 are arranged to form a closed annular wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com