Steel strand insertion guiding device

A technology of guiding device and steel strand, which is applied in the field of engineering and can solve the problems of low beam penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

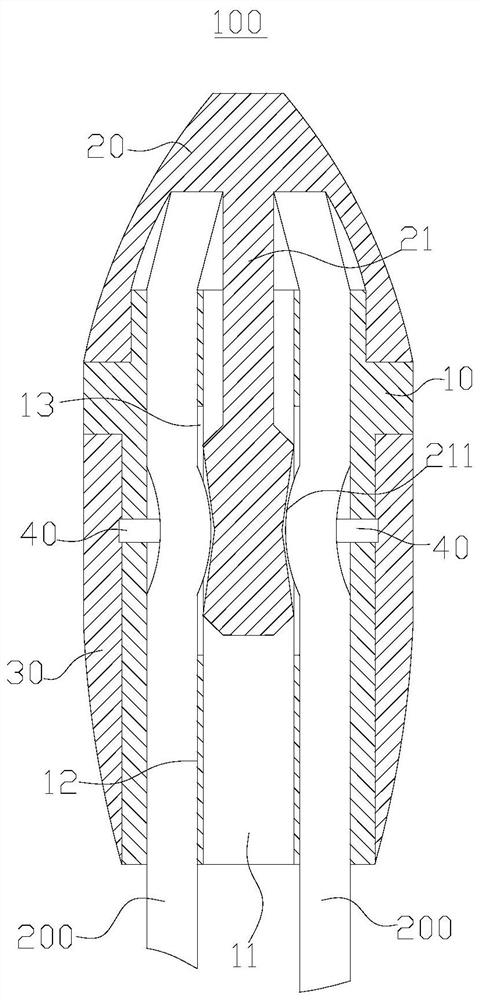

[0051] The embodiment of the present application provides a steel strand insertion guide device 100 , which can improve the bundle penetration efficiency of the steel strand 200 . The specific structure of the steel strand insertion guide device 100 will be described in detail below with reference to the accompanying drawings.

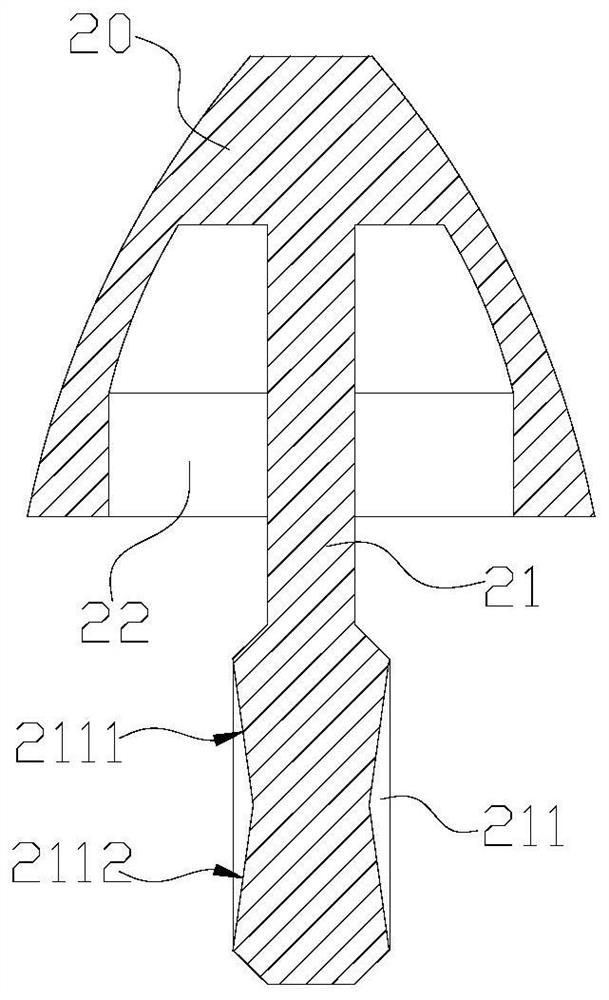

[0052] Please refer to figure 1 , figure 1 A structural diagram of a steel strand insertion guiding device 100 provided in some embodiments of the present application, the steel strand insertion guiding device 100 includes a body 10 , a guiding head 20 , a movable sleeve 30 and a plurality of locking pins 40 .

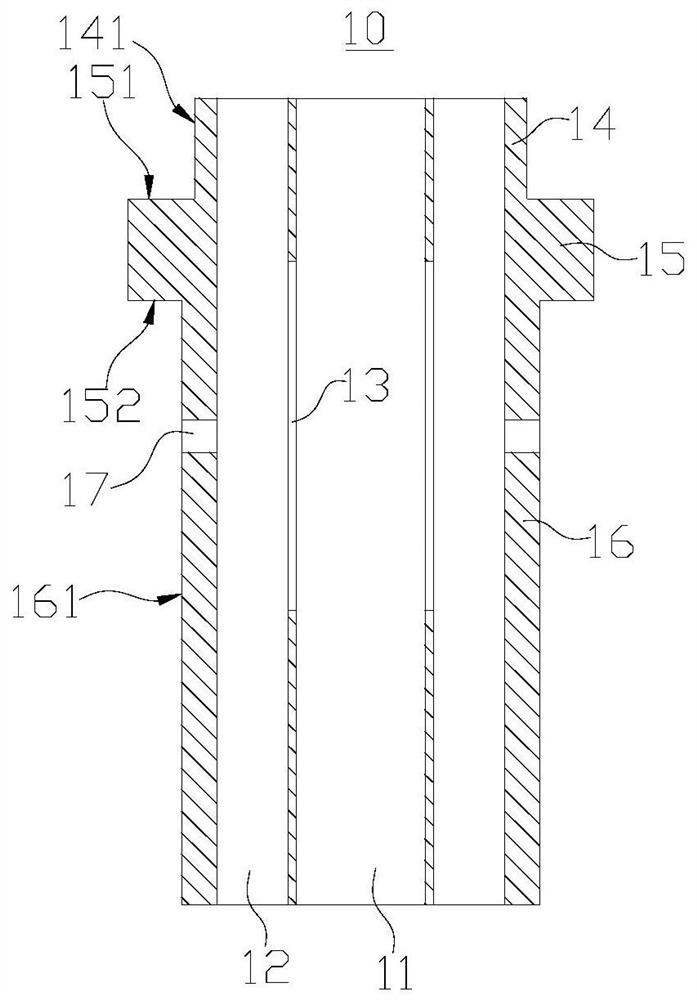

[0053] The main body 10 is provided with a central hole 11, a plurality of threading holes 12 and a plurality of connecting holes 13, the central hole 11 and the threading holes 12 both pass through the two ends of the body 10 in the axial direction, and the plurality of threading holes 12 are centered around the central hole 11. Distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com