Steel bar mesh clamping device and steel bar mesh cage forming equipment

A steel mesh and clamping device technology, which is applied to ceramic molding machines and manufacturing tools, can solve the problems of inconvenient operation and low production efficiency of steel mesh cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

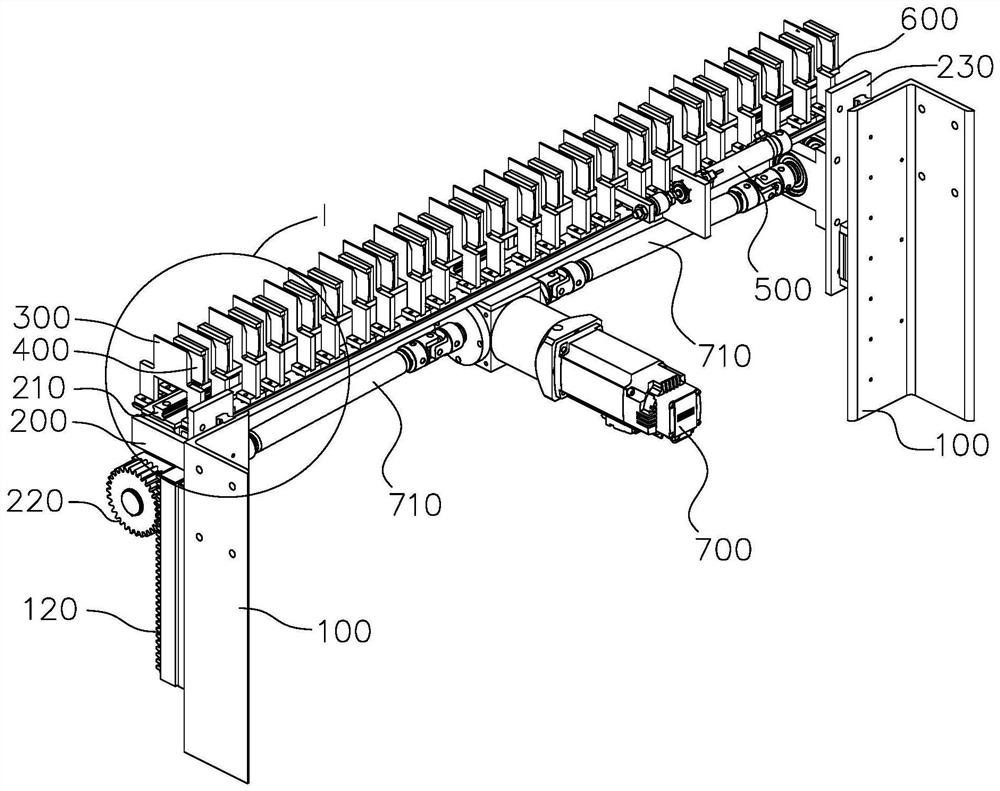

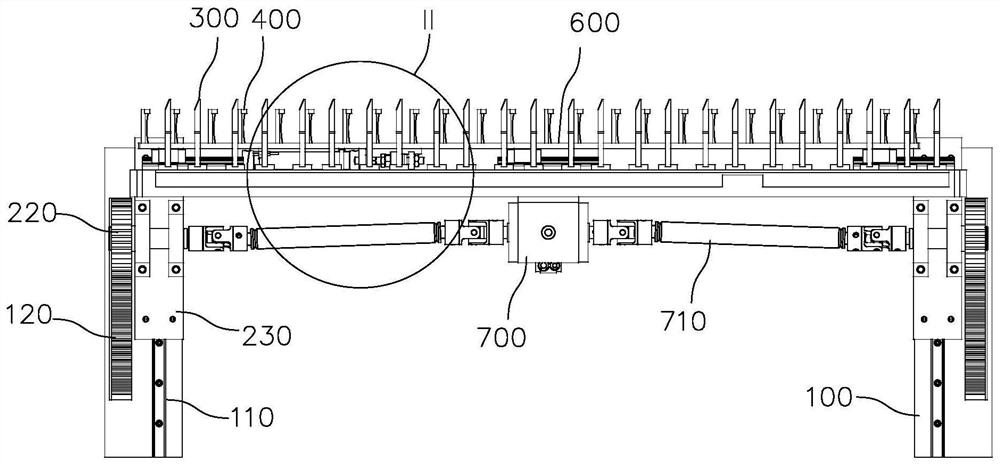

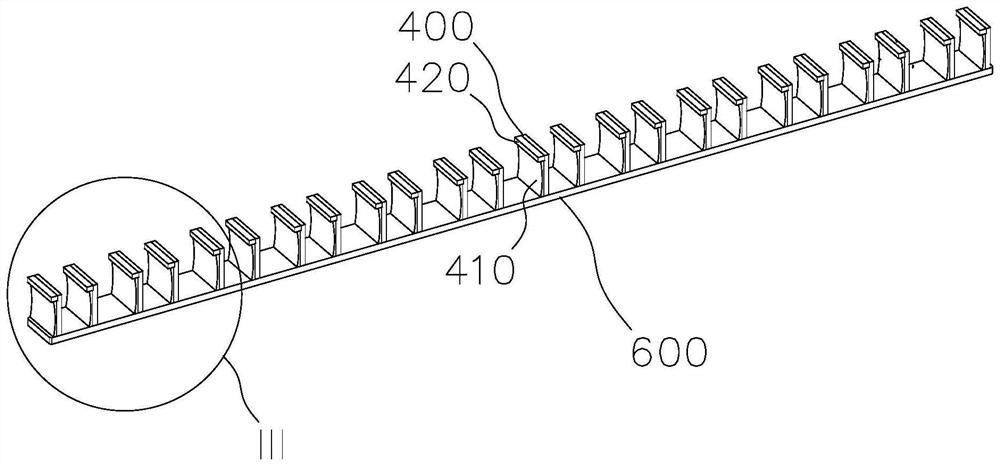

[0047] The steel mesh cage in the autoclaved aerated concrete slab is generally formed by connecting pairs of steel mesh sheets 800 through a plurality of buckles, and each buckle is respectively snapped to the edge longitudinal bars of two steel mesh sheets 800, so that the two The steel mesh sheets 800 are kept at a certain distance and fixedly connected as a whole, thereby forming a steel mesh cage.

[0048] In the prior art, generally by manual operation, the distance between two opposite steel mesh sheets 800 is first adjusted according to the size of the mesh cage, and then the buckles are respectively snapped into the longitudinal reinforcement bars 810 of the two steel mesh sheets 800 by using a steel bar networking device. . When the buckle is installed, the longitudinal steel bar 810 is easily bent and deformed under the force, which makes it difficult to be buckled into the buckle, resulting in low production efficiency and low yield.

[0049] It should be noted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com