Corrugated board cutting device capable of beveling without rim charge

A corrugated cardboard and cutting device technology, which is applied in metal processing and other directions, can solve the problems of crooked cutting and damage to the shape of corrugated cardboard, and achieve the effect of avoiding crooked cutting, facilitating operation, and ensuring fixed immobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

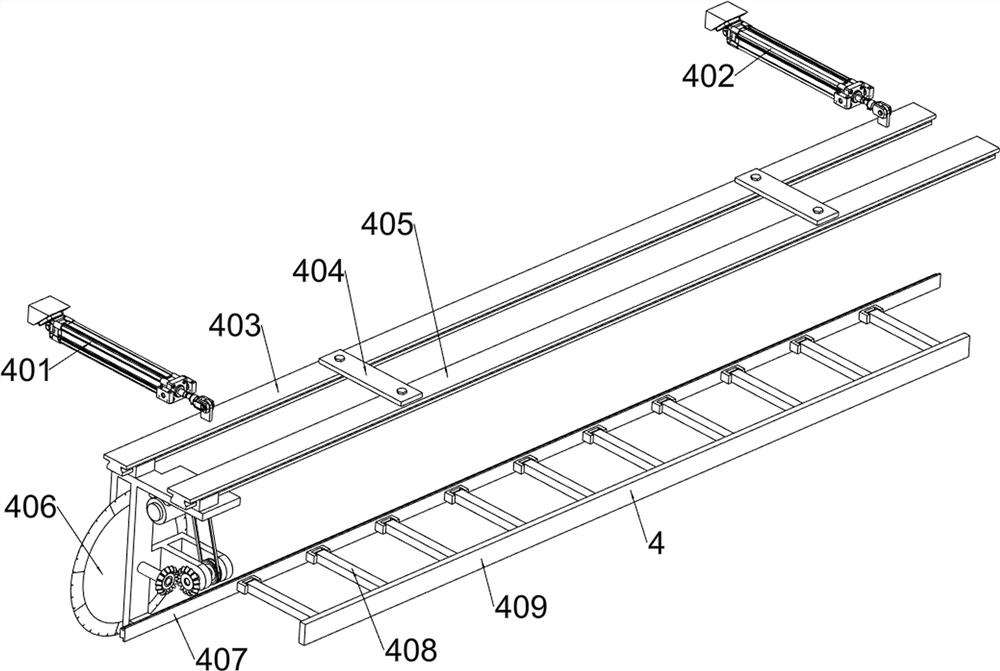

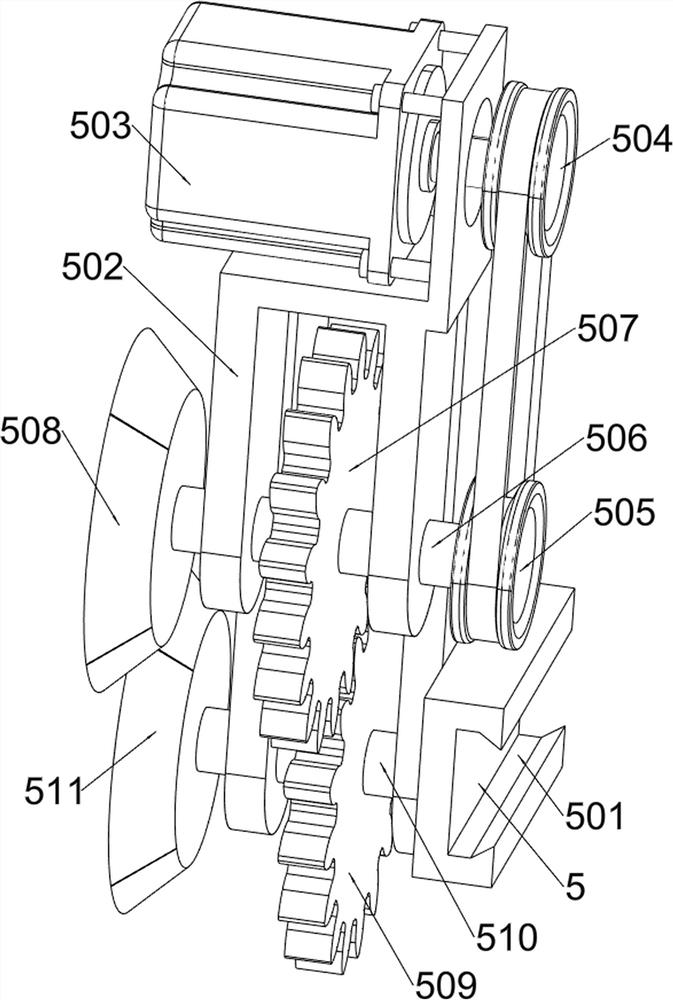

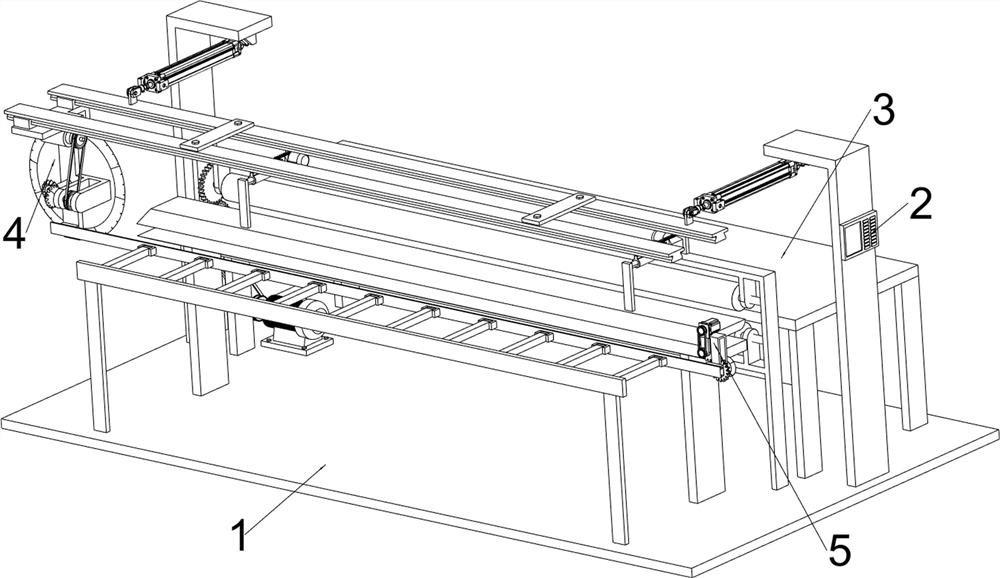

[0081] A corrugated cardboard cutting device capable of obliquely cutting edgeless material, such as Figure 1-10 As shown, it includes support 1, control panel 2, feeding auxiliary system 3, cutting system 4 and edge material removal system 5; support 1 is used to support the device; control panel 2 is fixedly connected to support 1; 1; the cutting system 4 is connected with the bracket 1; the trim removal system 5 is connected with the cutting system 4.

[0082] Working principle: When using this device, first install the device horizontally at the place where it needs to be used, connect the external power supply, and manually open the control panel 2 to control the operation of the device, put the corrugated cardboard to be cut into the feeding auxiliary system 3, and the feeding auxiliary system The system 3 clamps the corrugated cardboard to prevent the corrugated cardboard from moving during cutting, and transfers the corrugated cardboard to the working position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com