Storage device of maintenance tools special for automobile machinery

A technology for maintenance tools and storage devices, which is applied in the direction of tool storage devices, manufacturing tools, cleaning methods and appliances, etc. It can solve the problems that affect the ease of twisting maintenance, difficulty in cleaning, and high wear and tear of storage equipment, so as to improve the convenience. and flexibility, eliminate the effect of anti-bonding operation, and improve the efficiency of auto repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

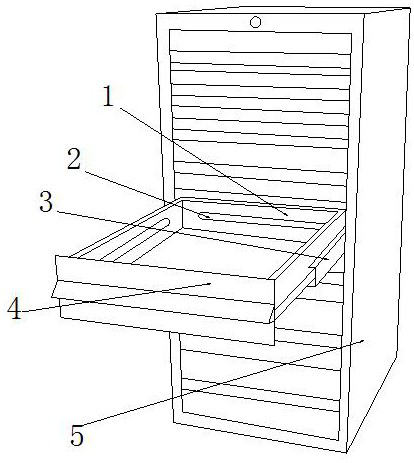

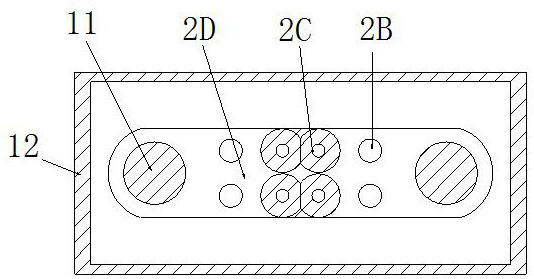

[0035] See Figure 1 - Figure 8 The present invention provides an automobile mechanical special repair tool storage device including: rear frame baffle 1, foam spray irrigation pipe 2, a guide boot bracket 3, a drawer groove 4, a cabinet 5, the foam spray irrigation The tube 2 is mounted on the front side of the rear frame baffle 1 and is in the same vertical surface, the foam spray irrigation transistor 2 is fastened to the guide boots holder 3, and the guide boots holder 3 mechanically connected to the drawer groove 4 The storage drawer groove 4 is mounted inside the cabinet groove body 5, and the foam spray irrigation manifold 2 is provided with a pressurized hole plate 2a, a void ear plate 2b, a cotton bubble thick wheel ring 2c, a cross tube groove 2D, The boosted hole plate 2a is inserted on the right side of the void ear plate 2b and is in the same horizontal plane, and the through hole plate 2b is nested together with the cotton bubble thick wheel ring 2C and penetrate each...

Embodiment 2

[0043] See Figure 1 - Figure 8 The present invention provides an automotive mechanical dedicated maintenance tool storage device, and other aspects are the same as in Example 1, and the difference is:

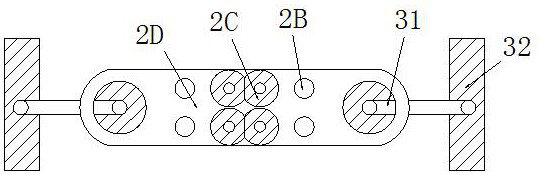

[0044] See image 3 The boot bracket 3 is composed of a cross-frame rod 31, a guide boot groove 32, and the cross lever 31 is mounted on the left side of the guide shoe slot 32 and is perpendicular to each other, the horizontal rod 31 and a guide boot plate. The groove 32 is fastened together, and the operation effect of forming a vertical lock-in-auxiliary end angle sliding adjustment is formed by the cross rod 31 and the guide boots groove 32.

[0045] See Figure 6 The horizontal frame 31 is composed of a truss lever buckle 311, a double wheel strip 312, and the truss rod buckle 311 is mounted inside the double wheel strip 312, the truss lever buckle 311 and a double wheel board. 312 is inserted into one and in the same vertical surface, the truss rod buckle 311 is a composite rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com