Plant extract extraction evaporator

A plant extract, evaporator technology, applied in evaporation, chemical instruments and methods, dispersed particle separation, etc., to achieve the effect of improving utilization and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

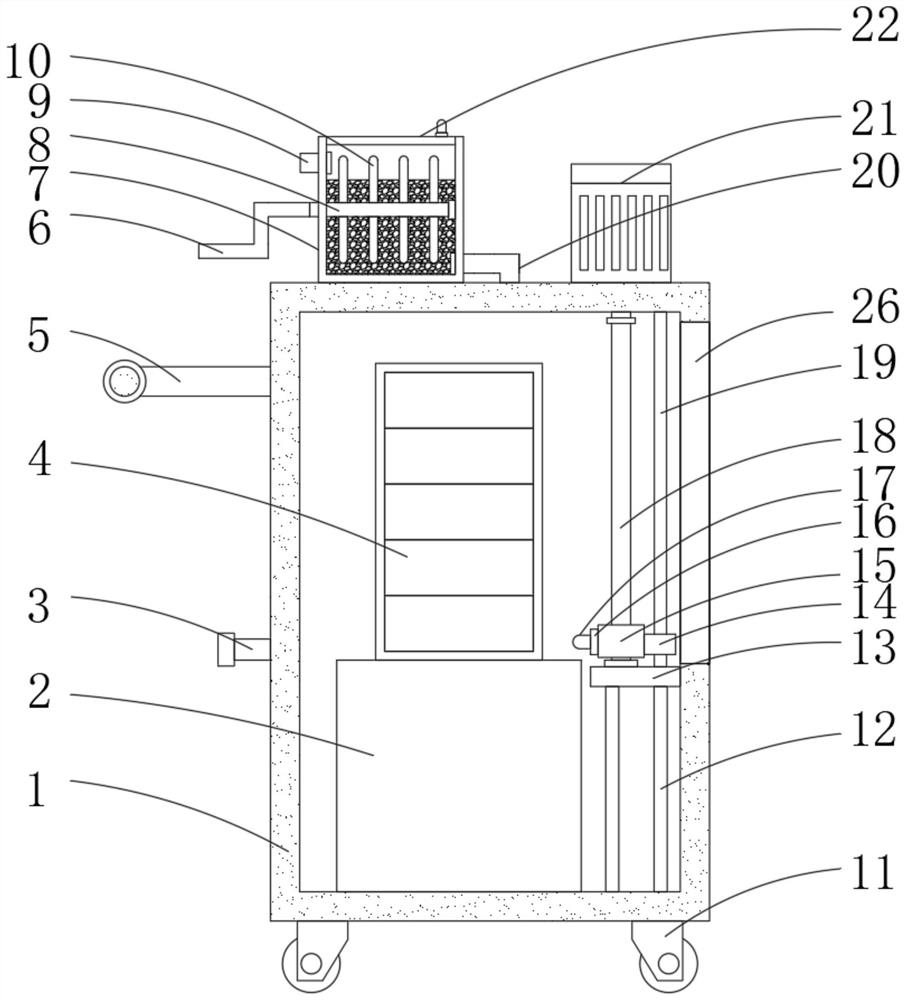

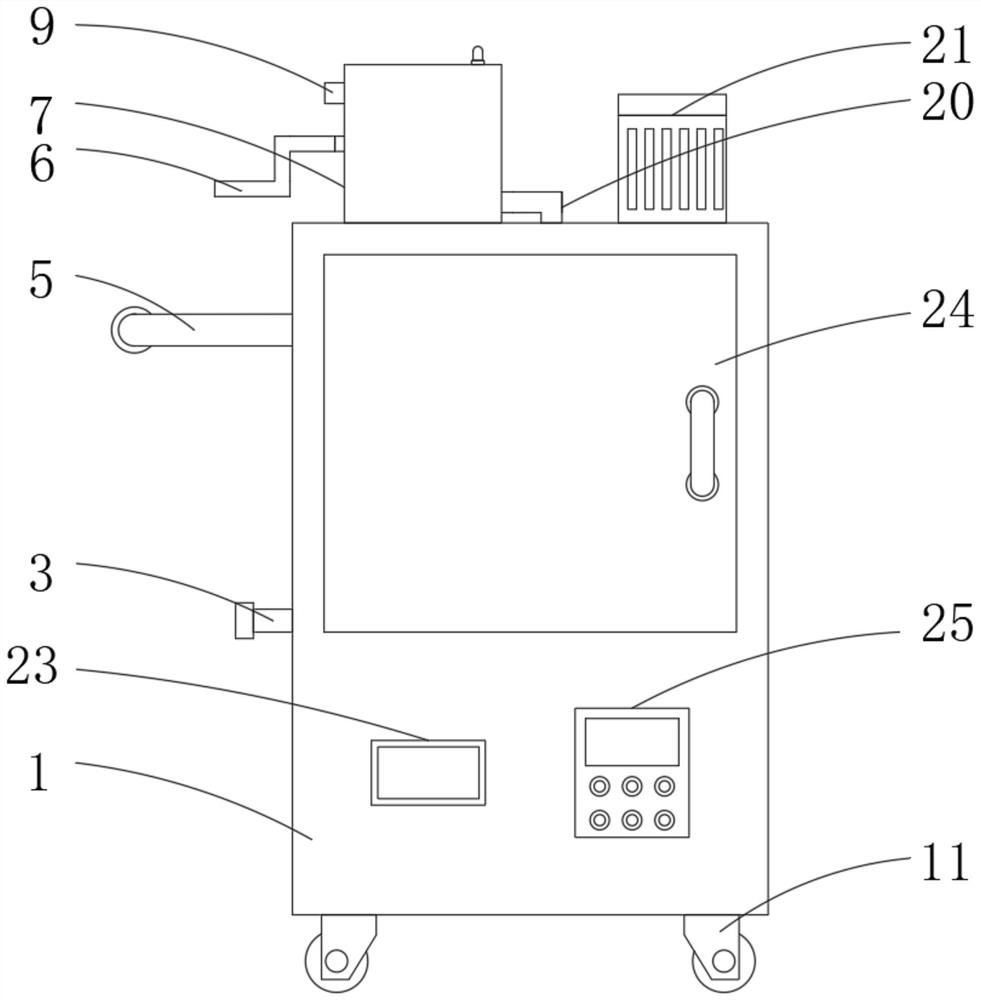

[0022] see Figure 1~2 , in the embodiment of the present invention, a kind of extracting evaporator of plant extract comprises evaporation extraction box 1, and heating box 2 is installed on the inner lower surface of evaporation extraction box 1, and graded steamer 4 is installed on the upper surface of heating box 2, and evaporation extraction The inner upper surface of box 1 is fixedly connected with support plate 13 by several connecting rods 12, and the upper surface of support plate 13 is connected with screw mandrel 18 in rotation, and the nut block 15 that matches on screw mandrel 18 is threaded, and support plate 13 The upper surface of the upper surface is fixedly connected with a slide bar 19, the slide bar 19 is set with a matching slide block 14, the side of the slide block 14 is fixedly connected with the side of the nut block 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com