Gas well scaling simulation device and simulation method

A simulation device and gas well technology, applied in the direction of measuring device, earthwork drilling, borehole/well components, etc., can solve the problem of low simulation accuracy of the gas well scaling simulation device, achieve real gas well environment, high simulation accuracy, heating high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

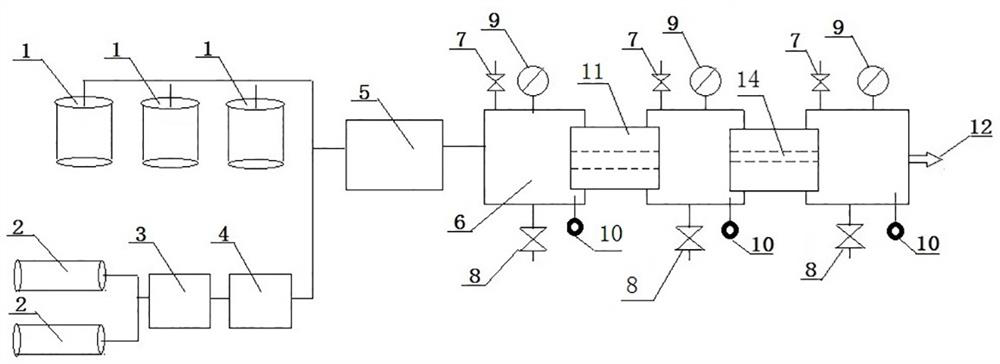

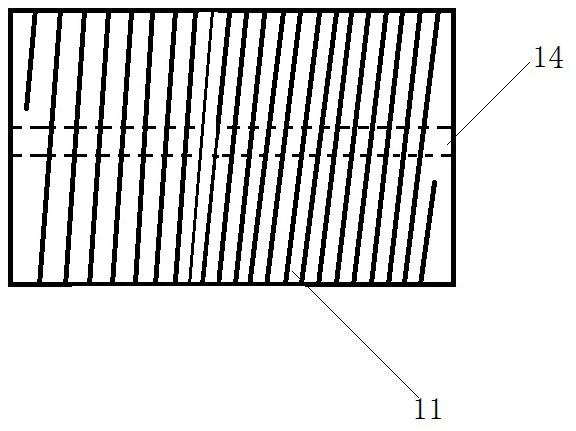

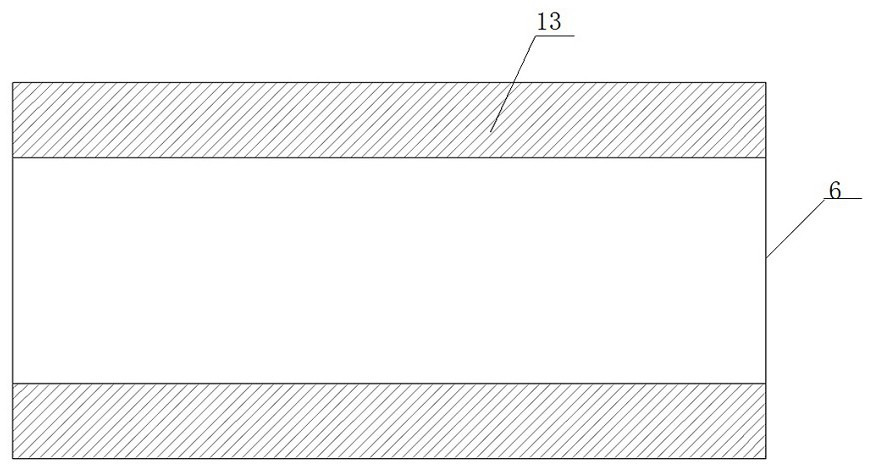

[0046] Such as figure 1 , figure 2 with image 3 As shown, the gas well scaling simulation device includes a gas storage device 1 , a liquid storage device 2 , a gas-liquid mixer 5 , and a scaling simulation tube 6 . Among them, the gas storage device 1 is a gas storage tank, which is mainly used to provide simulated gas; the liquid storage device 2 is a liquid storage tank, which is mainly used to provide simulated liquid. Wherein, the simulated gas can be nitrogen and carbon dioxide, and the simulated liquid can be samples such as simulated formation water and real formation water with different salinities. Both the gas storage device 1 and the liquid storage device 2 are in communication with the gas-liquid mixer 5. In the gas-liquid mixer 5, the above-mentioned simulated gas and simulated liquid are mixed to obtain an experimental fluid. The downhole scaling situation is simulated in the scale simulation tube.

[0047] It should be noted that the number of gas storage...

Embodiment 2

[0055] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiment 1 is that: only two fouling simulation tubes 6 are provided, and at this time, there is only one throttle nozzle 11 .

Embodiment 3

[0057] Such as Figure 5 As shown, the difference between this embodiment and the above-mentioned embodiment 1 is that the throttling structure adopts a throttle valve 14, which can realize the effect of throttling and reducing pressure, and the two adjacent fouling simulation pipes respectively correspond to throttling The ports at both ends of the valve are threaded, which is convenient to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com