A multi-stage shock-isolation friction pendulum support with pull-out resistance

A friction pendulum support and shock isolation technology, which is applied in the field of building shock isolation, can solve problems such as poor pull-out resistance, and achieve the effect of stabilizing the upper structure and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

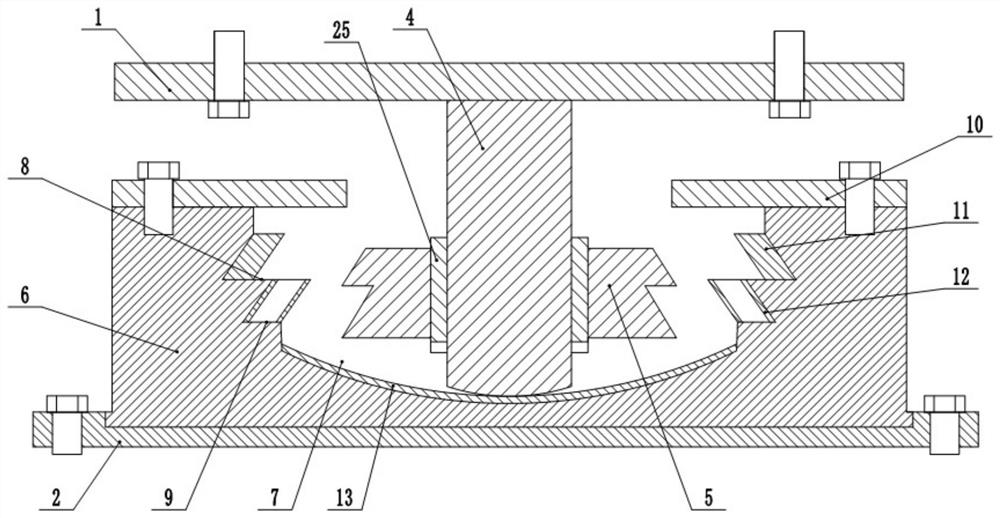

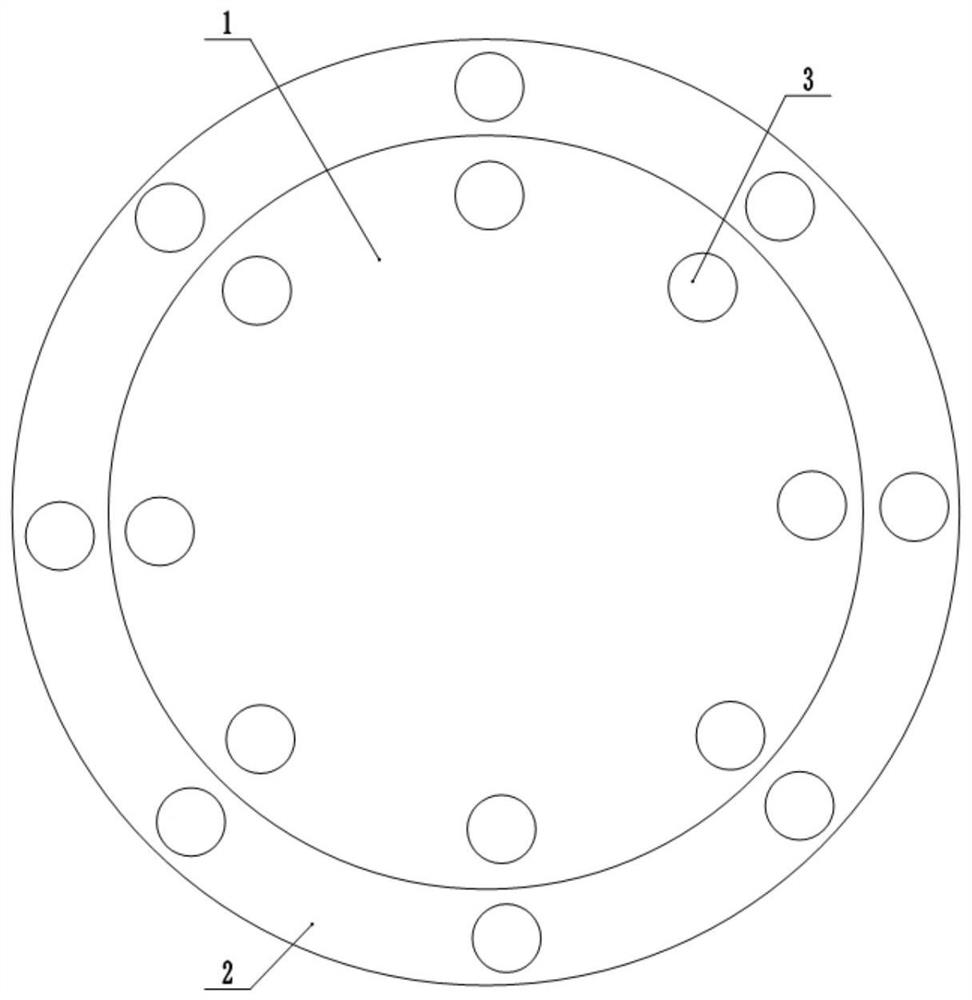

[0026] like figure 1 , figure 2 and image 3 Shown:

[0027] A multi-stage shock-isolation friction pendulum support with pull-out resistance, comprising an upper sealing plate 1 and a lower sealing plate 2, both of which are reserved with a number of evenly distributed bolt holes 3; the upper sealing plate The bottom of the plate 1 is welded with a middle block 4, and the middle block 4 is partially threaded. The middle block 4 is threaded with a threaded sleeve 25, and the sleeve 5 coaxial with the middle block 4 is fixed on the threaded sleeve 25. The sleeve 5 includes two identical and fixedly connected circular platforms, and the diameter of the circular platform gradually increases from top to bottom; a circular groove is opened on the lower sealing plate 2, and a lower support 6 is fixedly connected to the groove by bolts , the lower support 6 is provided with a partially spherical connection groove 7, the connection groove 7 is offset against the middle block 4; th...

Embodiment 2

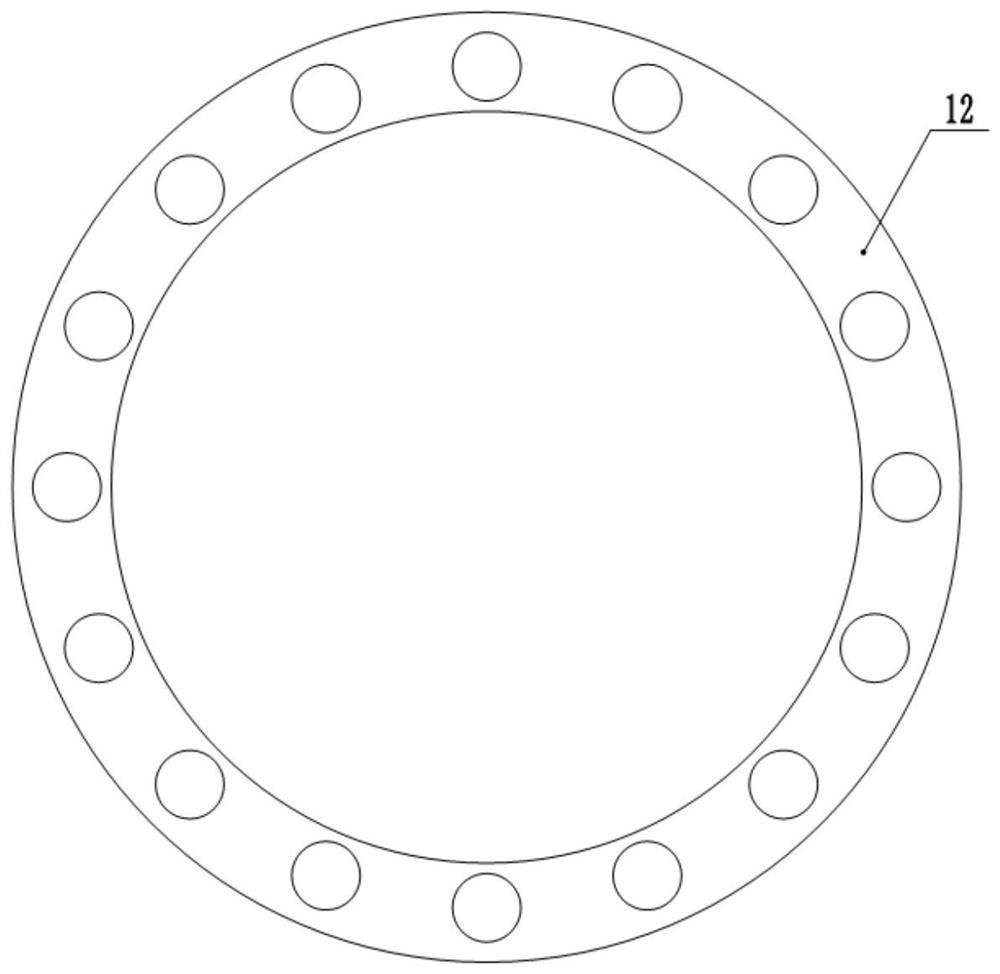

[0038] like figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0039] On the basis of Embodiment 1, optionally, the inner wall of the annular limit baffle 10 is provided with a number of chutes 14 distributed in a circular array, all of which are facing the middle block 4, and all of which slide in the chutes 14 Connected with a shock absorber column 15, a support rod 16 is arranged between the shock absorber column 15 and the middle block 4, and the two ends of the support rod 16 are respectively connected with the shock absorber column 15 and the middle block 4 through a ball joint 17; A buffer spring 18 is arranged between the shock-absorbing column 15 and the slide groove 14 .

[0040] During the swing process, the middle block 4 pushes the shock absorbing column 15 on one side of the swing direction to slide in the chute 14 through the support rod 16, thereby squeezing the corresponding shock absorbing spring, while the middle block 4 pulls the other side through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com