Method for extracting and purifying sugar alcohol with high purity and high yiel

A purification method and high-purity technology, applied in the field of water treatment, to achieve the effect of reducing resource consumption, increasing permeability, and efficient batch switching operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

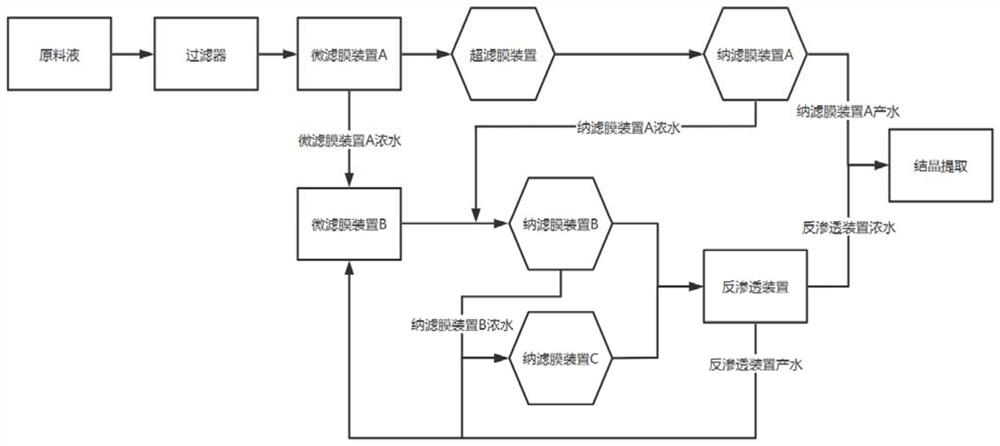

Method used

Image

Examples

Embodiment 1

[0019] A high-purity and high-yield extraction and purification method for sugar alcohols, comprising the steps of:

[0020] The composition of the raw material liquid contains 20% of sorbitol, 1.5% of magnesium sulfate, 2% of protein impurities, and the purity of sugar alcohol is 85%.

[0021] First, the raw material liquid is subjected to coarse filtration through a filter to remove waste residue and visible impurities in the raw material liquid; the raw material liquid after deslagging is further removed through a microfiltration membrane device A, and the microfiltration membrane device A adopts a ceramic membrane with a pore size of 100nm. The operating pressure is 10kg; the water produced by the microfiltration membrane device A enters the ultrafiltration membrane device to filter the impurity protein in the feed liquid. The product water from the membrane filtration device enters the nanofiltration membrane device A for circulation and concentration. The parameters of t...

Embodiment 2

[0024] A high-purity and high-yield extraction and purification method for sugar alcohols, comprising the steps of:

[0025] The composition of the raw material liquid contains 18% of xylitol, 0.8% of magnesium sulfate, 5% of protein impurities, and the purity of the sugar alcohol is 78%.

[0026] First, the raw material liquid is subjected to coarse filtration through a filter to remove waste residue and visible impurities in the raw material liquid; the raw material liquid after deslagging is further removed through a microfiltration membrane device A, and the microfiltration membrane device A adopts a ceramic membrane with a pore size of 100nm. The operating pressure is 10kg; the water produced by the microfiltration membrane device A enters the ultrafiltration membrane device to filter the impurity proteins in the feed liquid. The product water from the membrane filtration device enters the nanofiltration membrane device A for circulation and concentration. The parameters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com