Building mortar bucket cleaning device

A cleaning device and ash bucket technology, applied in the field of construction equipment cleaning, can solve problems such as difficult cleaning, cement condensation, and damage to the inner wall of the ash bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] The first preferred embodiment:

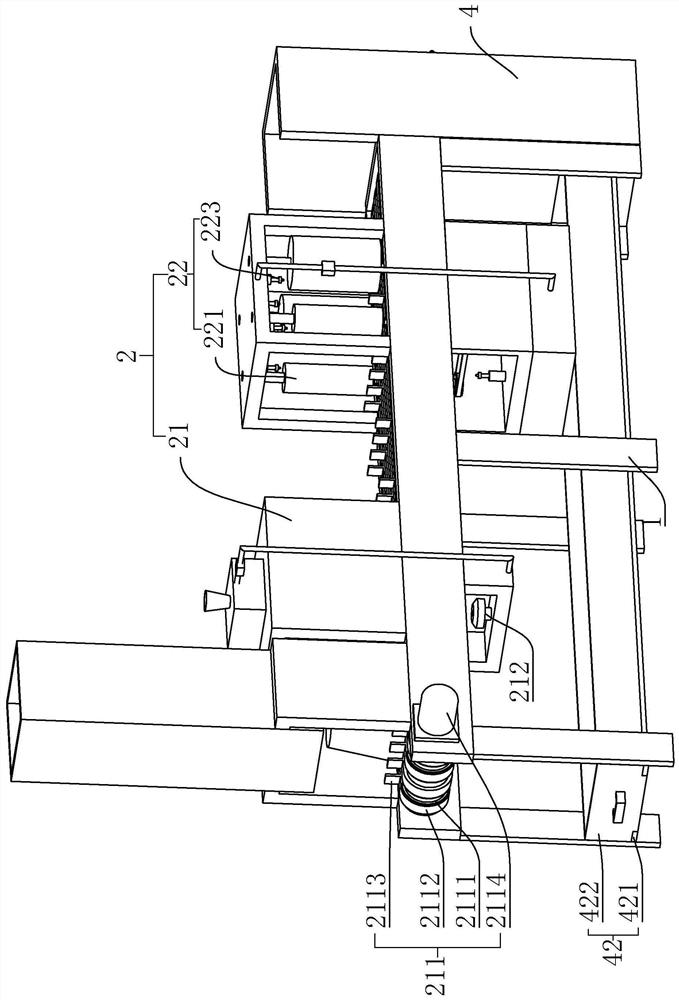

[0032] A construction ash bucket cleaning device, such as figure 1 As shown, a support 1 is included, and the support 1 is provided with a drop mechanism 3 for placing the ash bucket and making the ash bucket drop to the transport assembly 211 in an orderly manner through the rotation of the counter object.

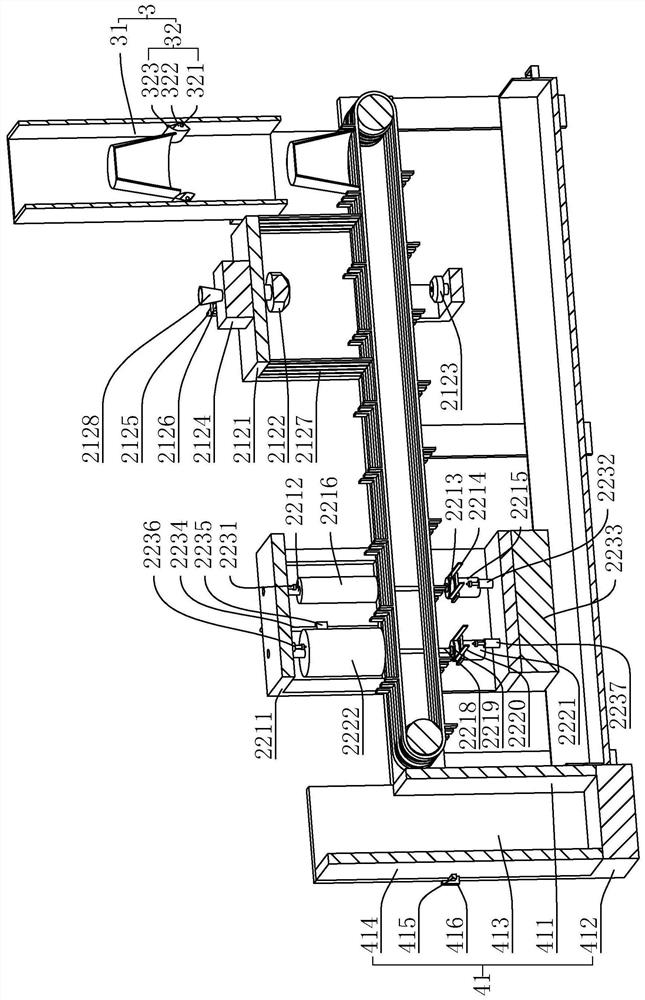

[0033] Such as figure 2 As shown, the drop mechanism 3 includes a placement bin 31 and a drop assembly 32 that changes the passing area through the rotation of the counter object so as to make the ash bucket drop in an orderly manner.

[0034] Such as figure 2As shown, the falling assembly 32 includes a set of rotating rods 321 arranged in the storage bin 31, the rotating rods 321 are connected to the inner walls on both sides of the storage bin 31, and the rotating rods 321 are placed horizontally; the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com