A method for adjusting the angle of the spray gun of an automatic painting equipment for auto repair

An automatic painting and angle adjustment technology, which is applied to mechanical equipment, injection devices, combustion engines, etc., can solve the problems of maintenance personnel requirements, high product costs, calculation errors, etc., and achieve simple and reliable calculation process and simple and clear motion model , the effect of lowering the threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

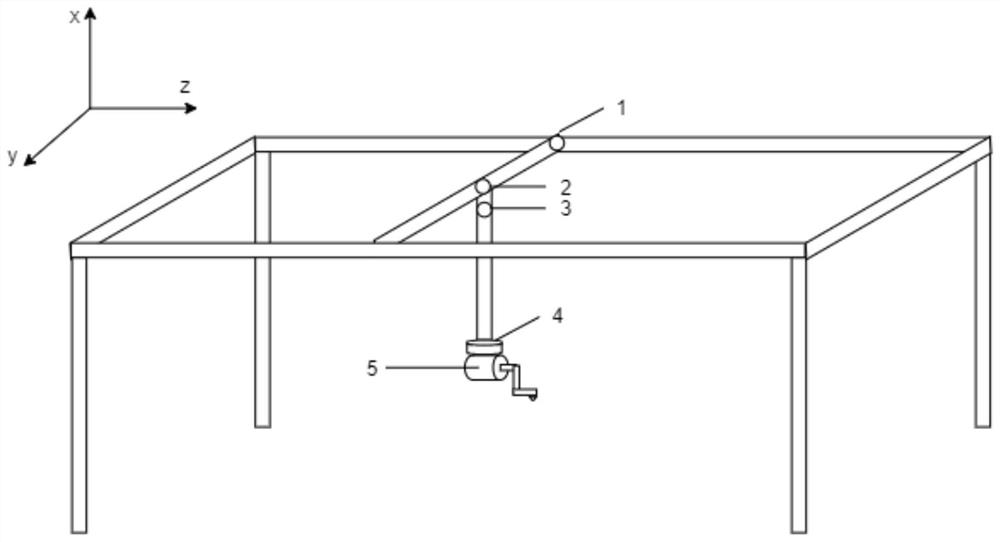

[0045] First establish the coordinate system of the car painting robot, such as figure 1 shown.

[0046] Build a truss for the spray gun robot to move freely in space. The movement range of the robot should not be less than the length, width and height of common models plus the necessary working space for the robot to paint.

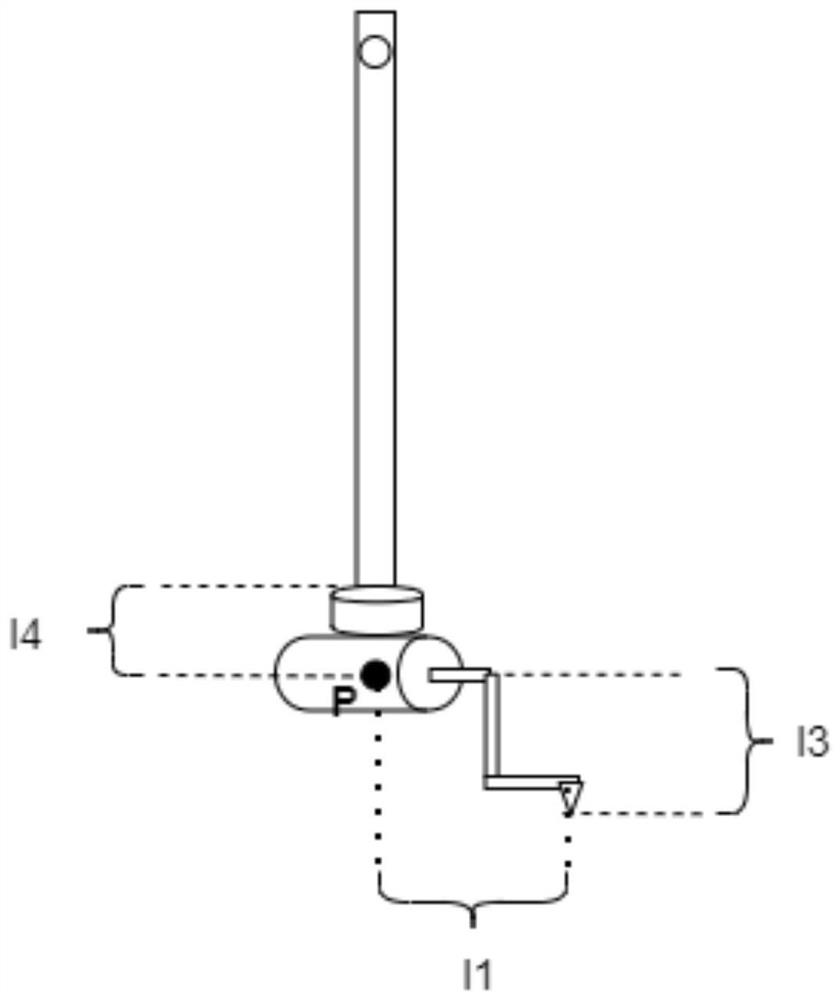

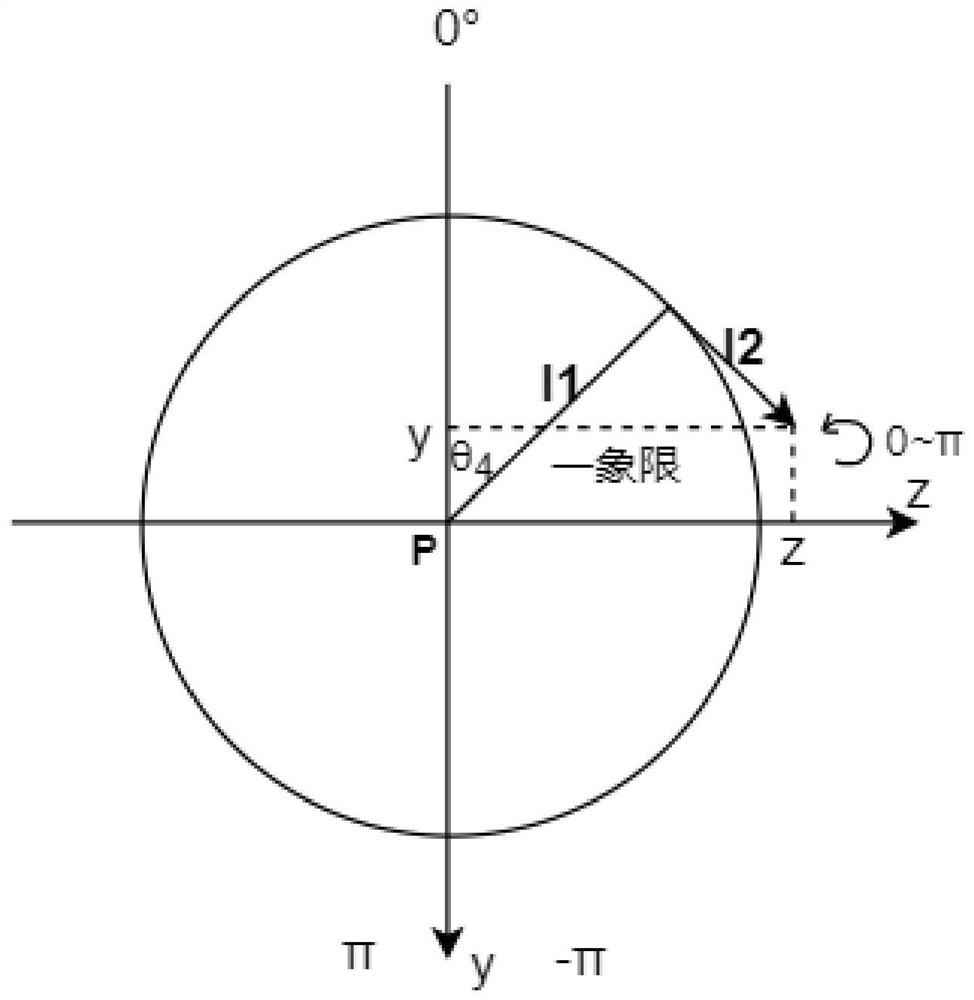

[0047] like figure 1 As shown, 5 sets of servo motors are installed on the truss to form a 5-axis robot. Specifically, 2 sets of them are installed on the truss, so that the robot can move in the horizontal direction, and the Z-axis servo motor 1 can make the robot move back and forth along the Z-axis, The Y-axis servo motor 2 enables the robot to move back and forth along the Y-axis; 1 set is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com