Automatic sampling machine for separating and sampling multiple parts of tire

A technology of automatic sampling and sampling machine, which is applied to sampling devices and other directions, can solve the problems of insufficient accuracy and low efficiency, and achieve the effects of high sampling accuracy, lowering manufacturing cost and improving sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

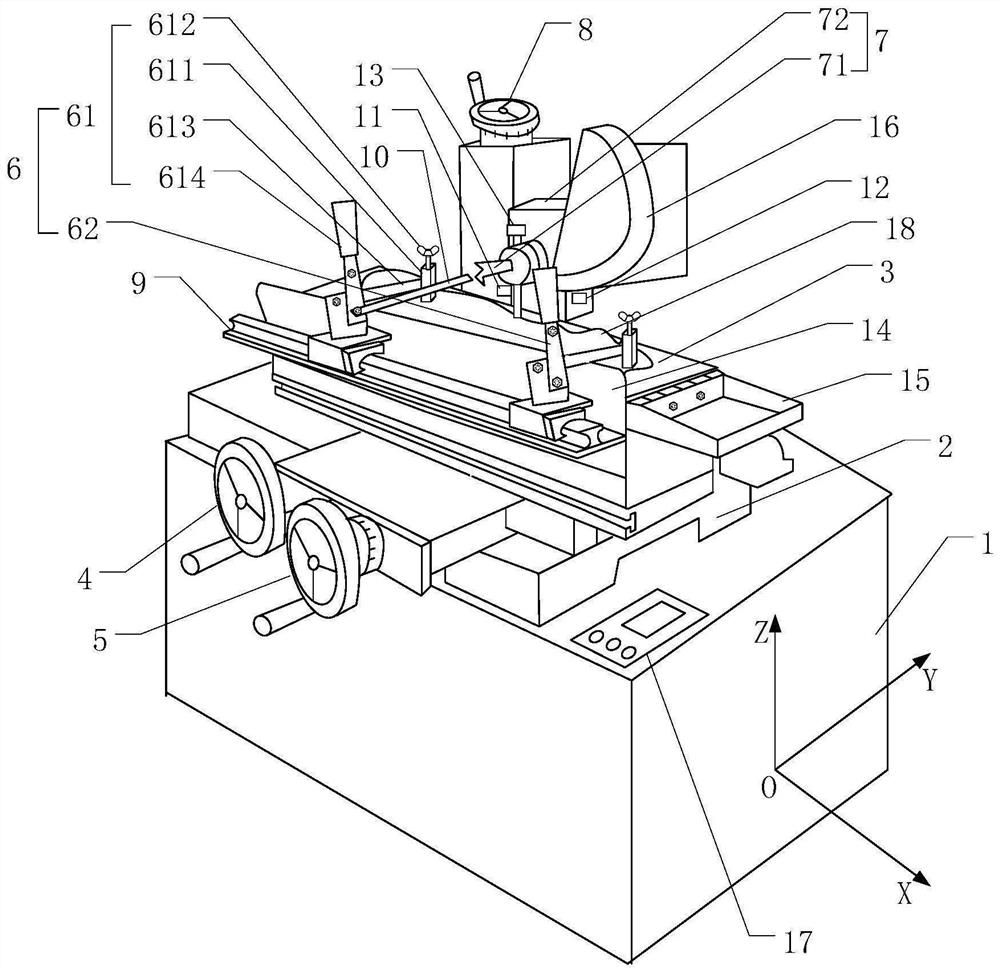

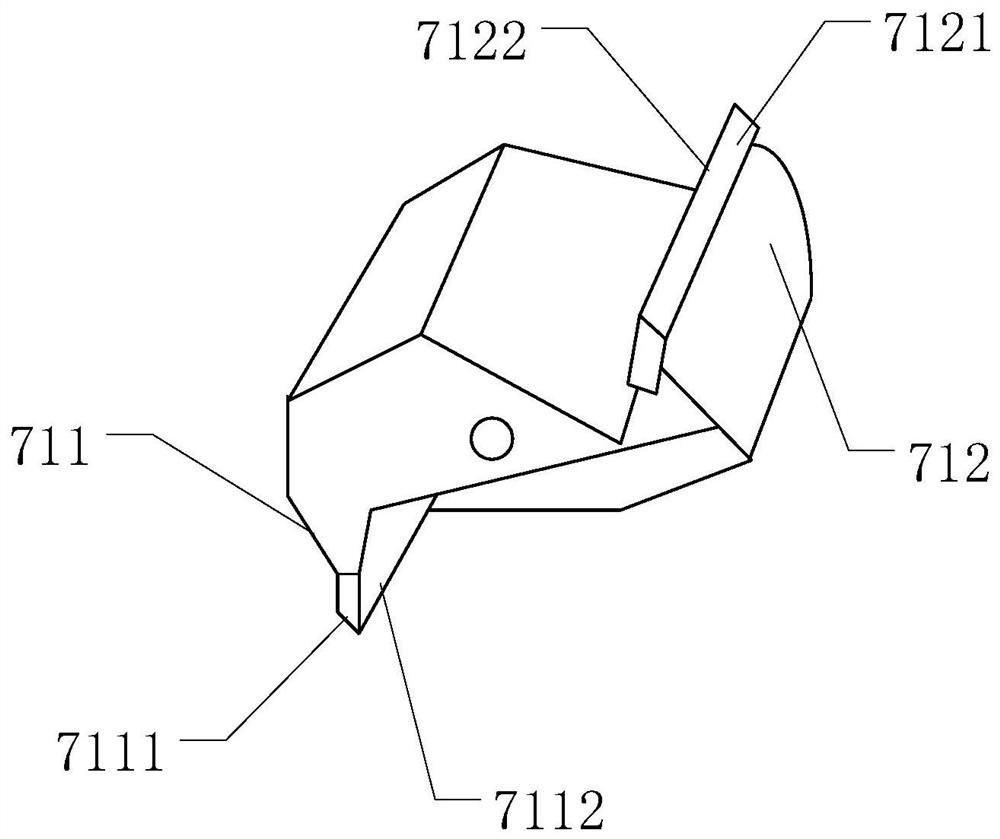

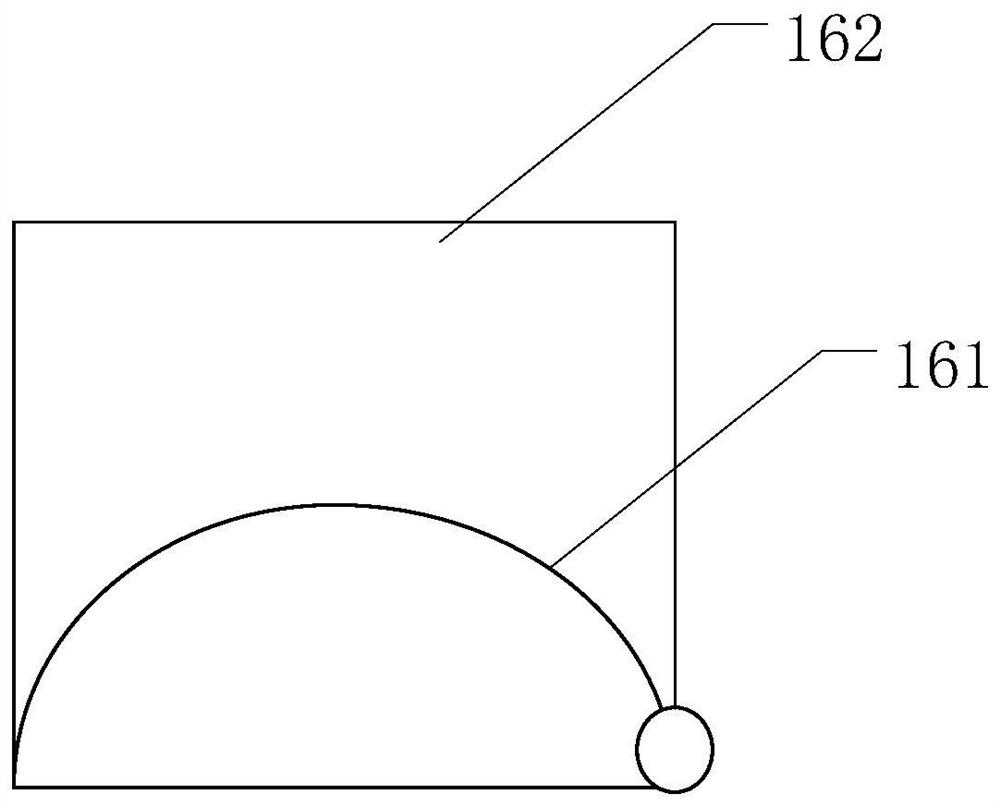

[0020] The embodiment of the present application provides an automatic sampling machine for separate sampling of multiple parts of tires, figure 1 It is a structural schematic diagram of an automatic sampling machine for separate sampling of tires in an embodiment of the present application, as shown in figure 1 As shown, the sampler includes: a power distribution control box 1, which is used to provide an operating current for the automatic sampler and control the electrical components of the automatic sampler; a workbench 2, which is arranged above the power distribution control box 1; the sample is placed Table 3, the sample placement table 3 is arranged above the workbench 2, and is used to place the tire assembly 18 to be sampled. The tire assembly 18 to be sampled is a tire component with a width cut along the tire radial direction and is less than 12 cm; the positioning adjustment device 6 is slidably installed on the The first side of the sample placement table 3 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com