Prefabricated building structure vacuum grouting device and construction method thereof

A building structure and prefabricated technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of pollution in the work site, increase in grouting pumps and press-in pipes, and slow operation speed, so as to improve work efficiency. Efficiency, reduced clogging, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

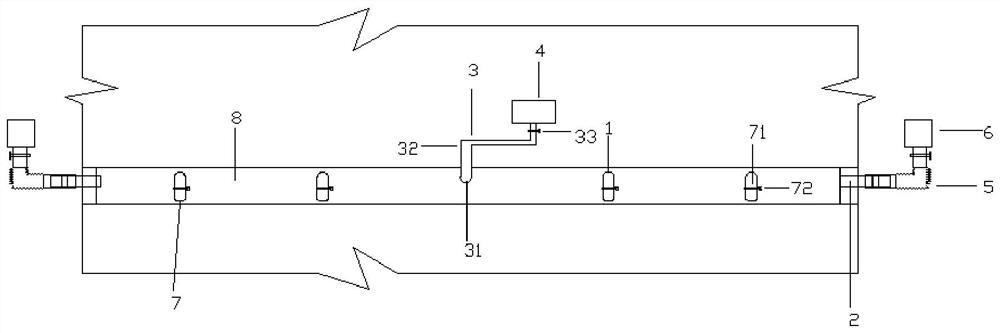

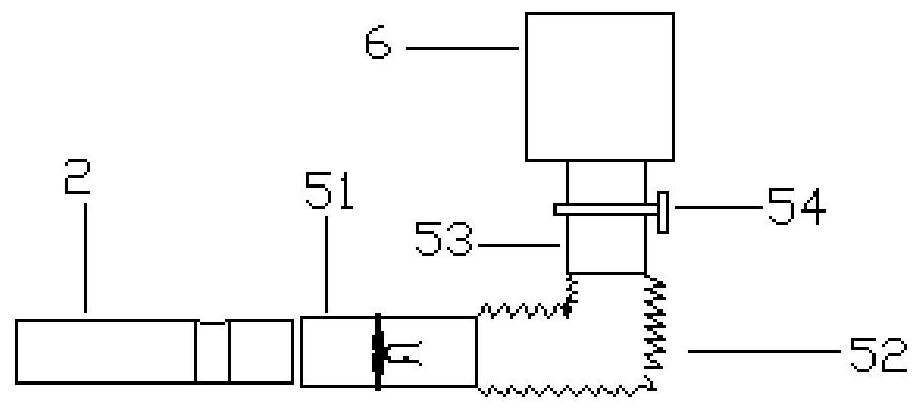

[0024] Figure 1-Figure 2 A prefabricated building structure vacuum grouting device is shown, the prefabricated building structure vacuum grouting device includes a grout inlet pipe 1, a grout outlet pipe 2, and a mixing drum sealingly connected to one end of the grout inlet pipe 1 through a grout inlet structure 3 4. An auxiliary structure 7 sealedly connected to one end of the pulp inlet pipe 1, a vacuum pump 6 sealed to one end of the pulp outlet pipe 2 through a slurry outlet structure 5,

[0025] The grout inlet pipe 1 communicates with the grout outlet pipe 2 through the hollow cavity 8 to be grouted, the mixing drum 4 is connected to the grout inlet pipe 1 at the center, and the auxiliary structure 7 is connected to the other inlet pipes. The slurry pipe 1 is connected.

[0026] The pulp feeding structure 3 includes a soft pulp feeding pipe 31, a pulp feeding connecting pipe 32 sealingly connected to one end of the soft pulp feeding pipe 31, and a pulp feeding valve 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com