Environment-friendly dip dyeing device with good dyeing effect for garment fabric

A kind of dyeing effect and environment-friendly technology, which is applied in the field of garment fabric processing, can solve the problems of fabric quality damage, poor effect, and inability to absorb dyes uniformly and fully, so as to achieve uniform and sufficient absorption and ensure the effect of dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

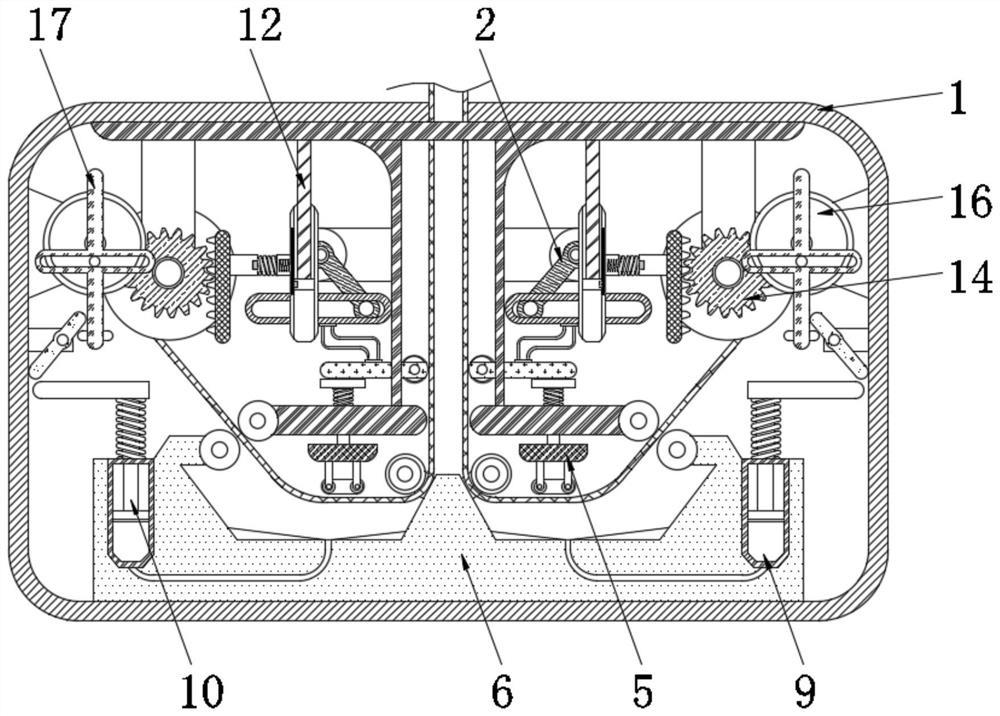

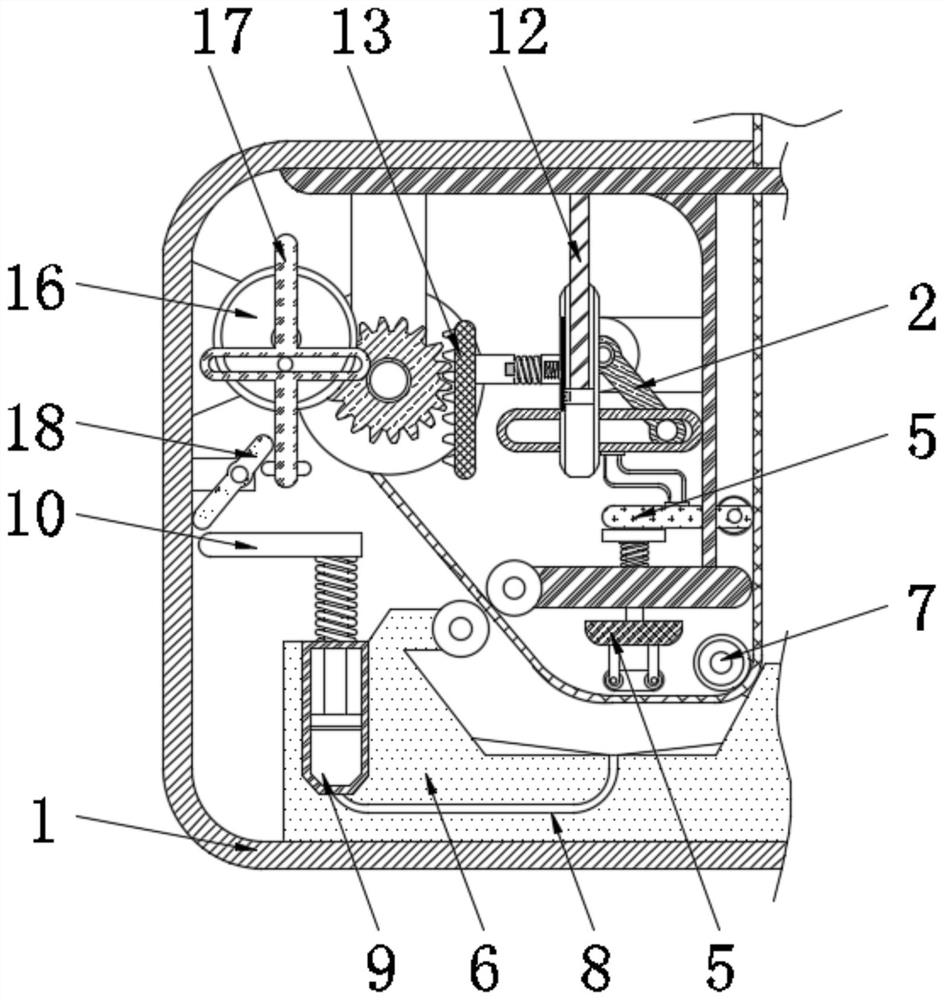

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The invention provides an environment-friendly dip-dyeing device for clothing fabrics with good dyeing effect, as attached figure 1 To attach Figure 4 Shown: including the dyeing bin 1, the inside of the dipping bin 1 is rotated and installed with a rotating plate 2, which is fixedly connected with the drive shaft, the bottom end of the rotating plate 2 is slidably installed inside the sliding plate 3, and the sliding plate 3 The bottom is fixedly installed with a hot pressing roller 4, and the inside of the sliding plate 3 is provided with a sliding hole corresponding to the rotating plate 2. The sliding plate 3 and the hot pressing roller 4 are arranged in parallel up and down, and a pressing wheel is arranged under the hot pressing roller 4. Rod 5, the outer surface of the pressing wheel rod 5 is sleeved with a spring, the bottom of the pressing wheel rod 5 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com