Method for regulating and controlling brightness of nickel button appearance

A bright, nickel button technology, applied in the field of nickel electrolysis, can solve the problem of changing the physical appearance of nickel buttons, and achieve the effect of changing the physical appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add the inorganic reducing agent sodium pyrosulfate and hydrogen sulfide to the nickel button electrolyte, adjust the redox potential of the electrolyte to -75mv, filter and remove the solid precipitate, and prepare the nickel button electrolyte with a reducing environment.

[0021] (2) The nickel button electrolytic growth additive was dissolved in the electrolyte, and the oxidation-reduction potential of the electrolyte was -75mv after the additive was added.

[0022] (3) After installing the cathode and anode in the electrolytic cell, turn on the power and the current density is 250A / m 2 Under the condition of electrolysis for 48h.

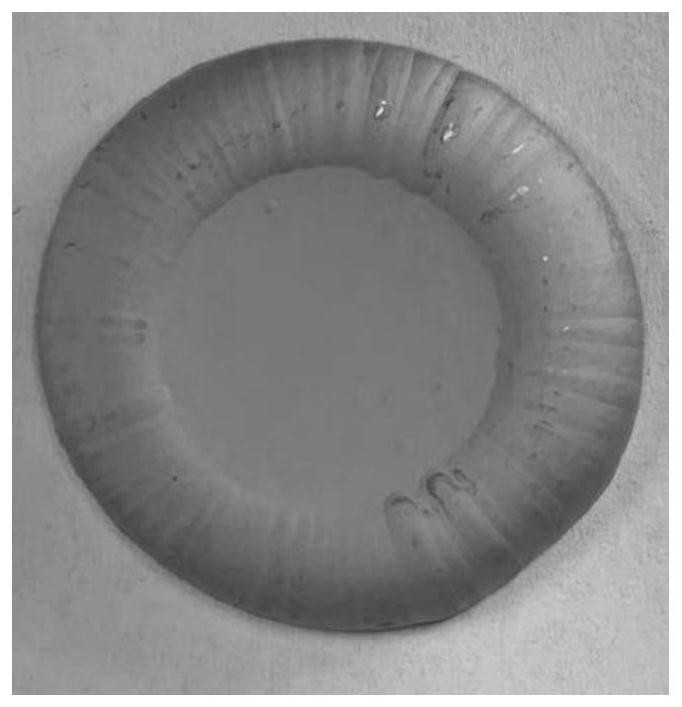

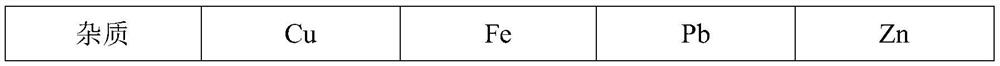

[0023] (4) After the electrolytic growth of the nickel button is completed, take out the nickel button and wash the electrolyte on the surface with water, then soak in hot water at 90°C for 10 minutes, take out the nickel button and quickly dry the surface moisture to obtain a matte surface nickel button. The analysis results of imp...

Embodiment 2

[0027] (1) Add the inorganic reducing agent sodium sulfite to the nickel button electrolyte, adjust the oxidation-reduction potential of the electrolyte to -60mv, and filter to remove the solid precipitate. A nickel button electrolyte with a reducing environment was prepared.

[0028] (2) The nickel button electrolytic growth additive is dissolved in the electrolyte, and the oxidation-reduction potential of the electrolyte is -60mv after the additive is added.

[0029] (3) After installing the cathode and anode in the electrolytic cell, turn on the power and the current density is 300A / m 2 Under the condition of electrolysis for 48h.

[0030] (4) After the electrolytic growth of the nickel button is completed, take out the nickel button and wash the electrolyte on the surface with water, then soak in hot water at 95°C for 5 minutes, take out the nickel button and quickly dry the surface moisture to obtain a matte surface nickel button. The analysis results of impurity compon...

Embodiment 3

[0034] (1) Add sodium hypochlorite, an inorganic oxidant, into the nickel button electrolyte, adjust the oxidation-reduction potential of the electrolyte to 300mv, and filter to remove solid precipitates. A nickel button electrolyte with an oxidizing environment was prepared.

[0035] (2) The nickel button electrolytic growth additive is dissolved in the electrolyte, and the oxidation-reduction potential of the electrolyte is 300mv after the additive is added.

[0036] (3) After installing the cathode and anode in the electrolytic cell, turn on the power and the current density is 200A / m 2 Under the condition of electrolysis for 24h.

[0037] (4) After the electrolytic growth of the nickel button is completed, take out the nickel button and wash the electrolyte on the surface with water, then soak in 80°C hot water for 5 minutes, take out the nickel button and quickly dry the surface moisture to obtain a bright surface nickel button. The analysis results of impurity componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com