A construction waste gasification environmental protection treatment equipment

A technology for environmental protection treatment and construction waste, which is applied in the direction of gasification process, fixed bed gasification, and production of combustible gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

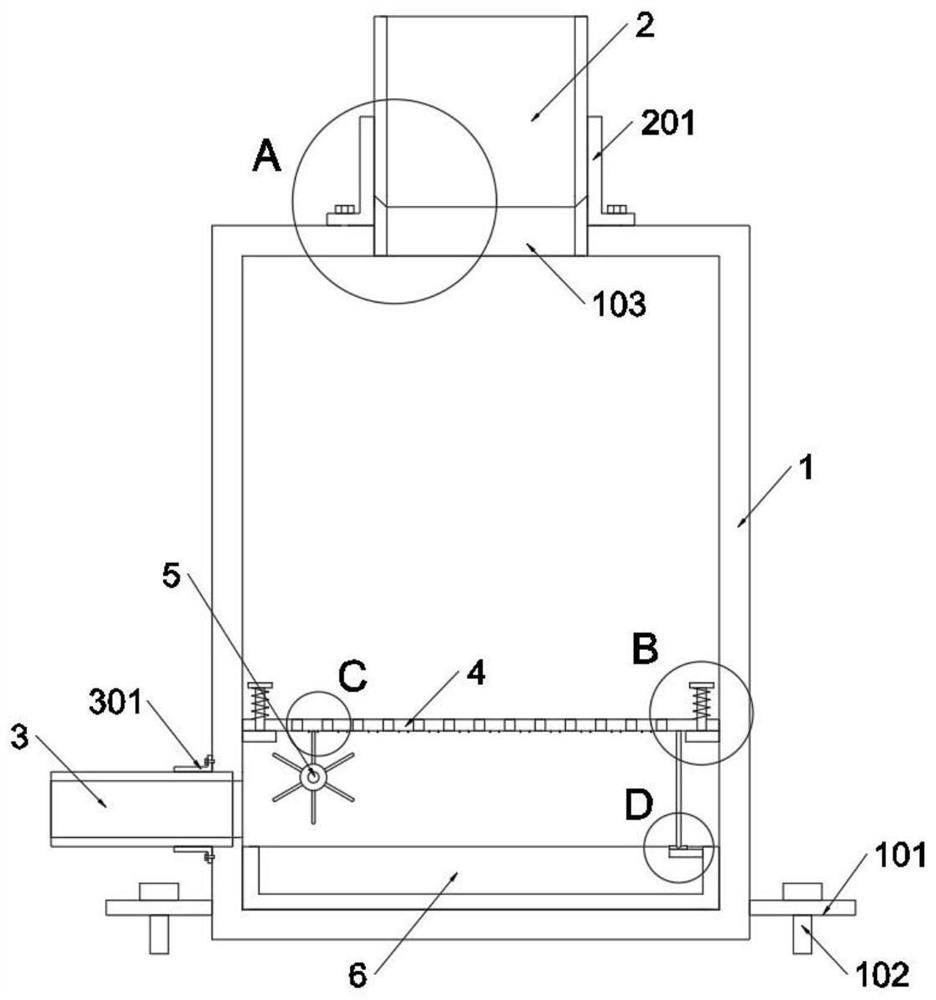

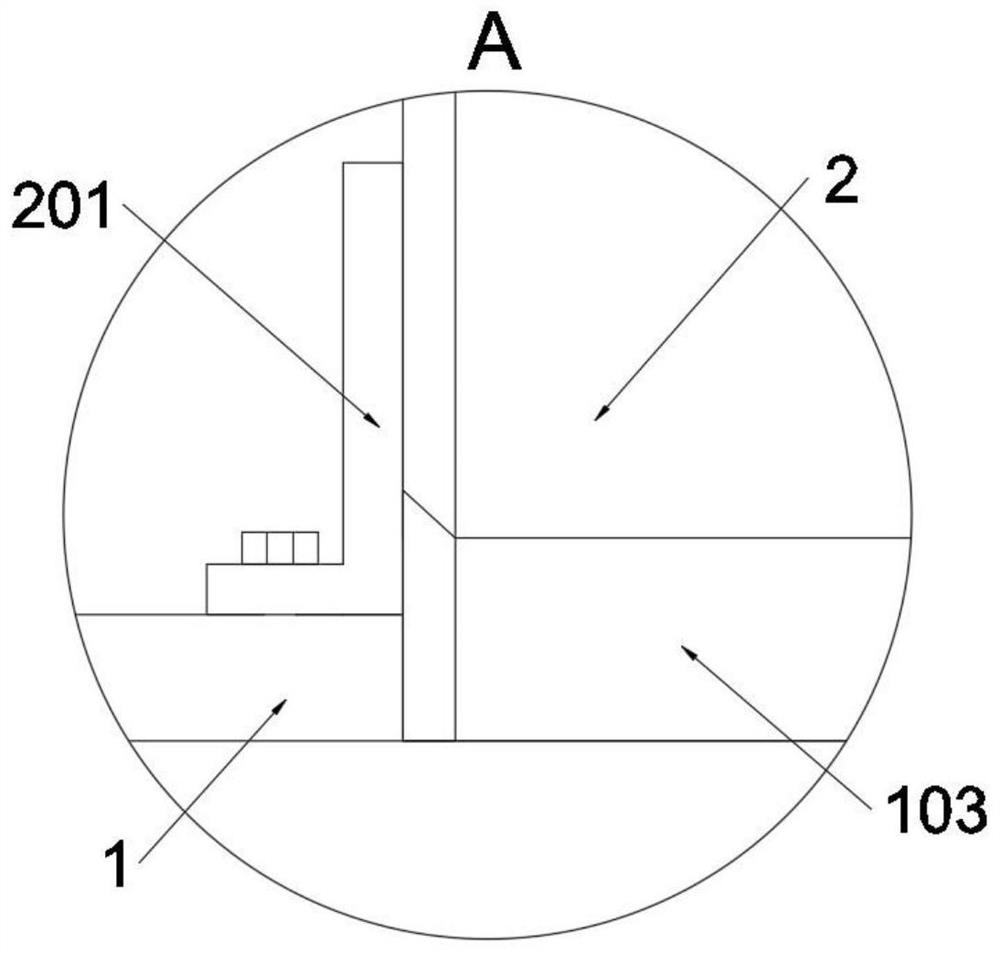

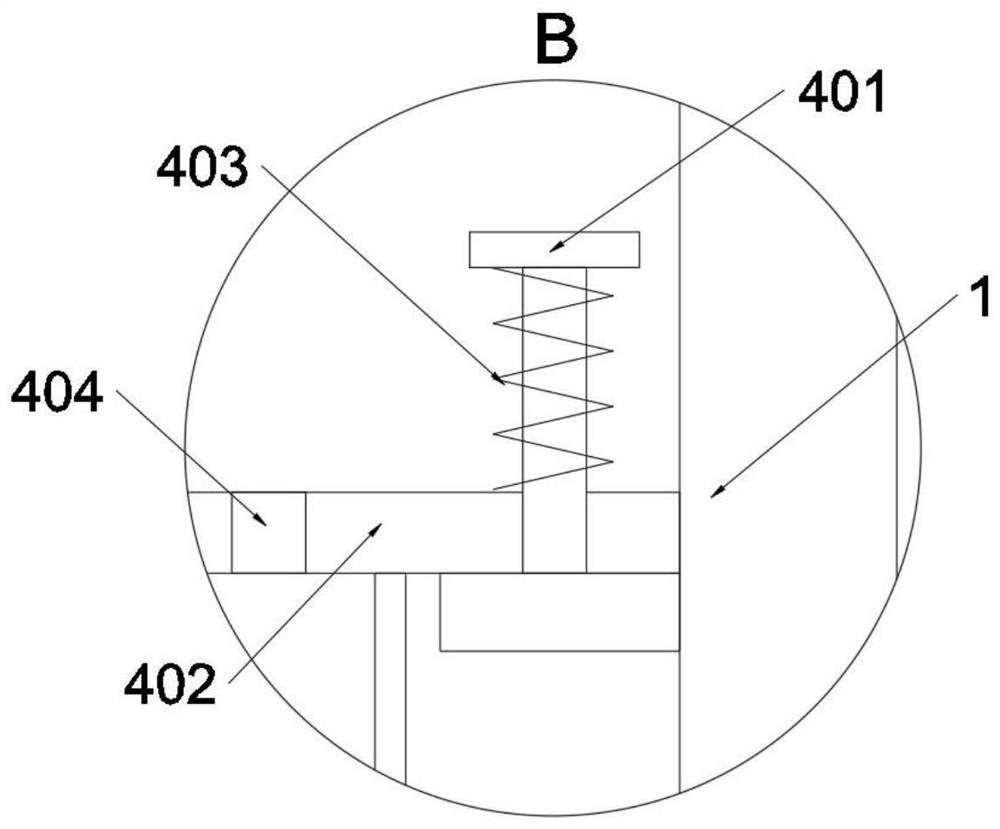

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a kind of construction waste gasification environmental protection processing equipment, which includes a box body 1; an exhaust pipe 2 is connected to the box body 1, and an air intake pipe 3 is also connected to the box body 1, and a blocking structure is installed in the box body 1 4; The drive structure 5 is installed in the box body 1, and the drawer 6 is plugged in the box body 1; refer to as figure 1 with Figure 4 , the blocking structure 4 includes protrusions A405, the protrusions A405 are welded on the bottom surface of the blocking plate 402 in a rectangular array, and the protrusions A405 and the through holes 404 are distributed in a staggered manner; the protrusions A405 are triangular prism rod-shaped structures, and The protrusions A405 welded in an array together form the auxiliary structure of the blocking plate 402, thereby preventing the possibility of large residues ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com