Method for carrying out high-strain-rate uniaxial compression test by using L-gauge

A uniaxial compression test, high strain rate technology, applied in the direction of applying stable tension/compression to test the strength of materials, instruments, measuring devices, etc. High precision and good data continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limitations to the present invention.

[0031] A pipeline steel is used to make a sample, and the method of using L-gauge for high strain rate uniaxial compression test involved in the present invention is further described in detail on a Gleeble-3800 thermal simulation testing machine. Specific steps are as follows

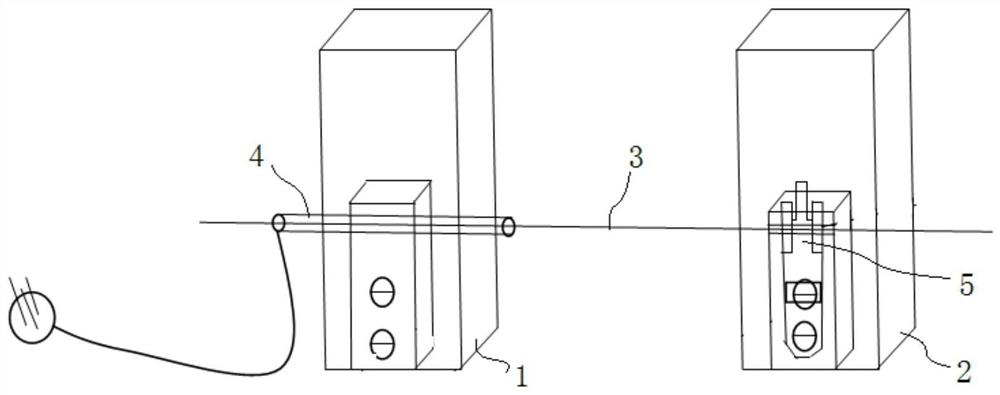

[0032] (1) In order to measure the change of the axial displacement of the sample more accurately, the L-gauge mode is used instead of the stroke mode. Such as figure 1 As shown, the L-gauge strain measurement mechanism includes a movable installation panel 1, a fixed installation panel 2, a movable long needle 3 and an L-gague displacement sensor 4, and the L-gauge displacement sensor 4 is fixedly installed on the movable installation pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com