Fire beer capable of being drunk after being heated and iced and preparation process thereof

A preparation process, fire beer technology, applied in the field of fire beer brewing, can solve the problem of not being suitable for consumption in winter, and achieve the effect of maintaining good taste and increasing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

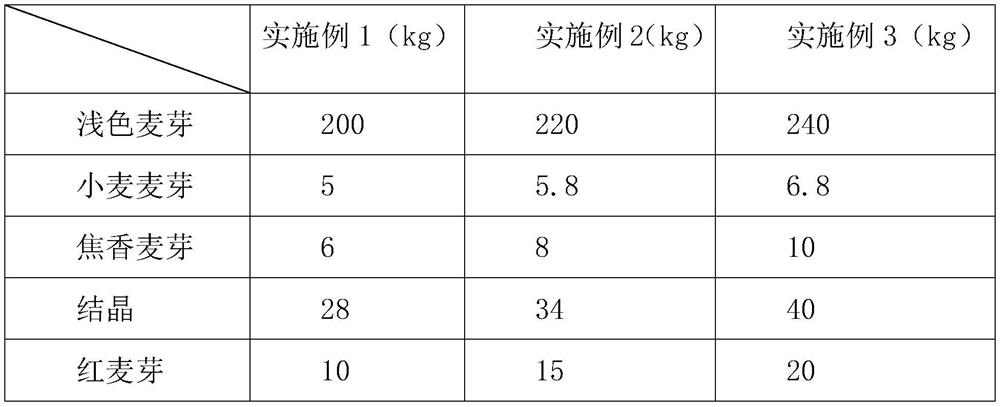

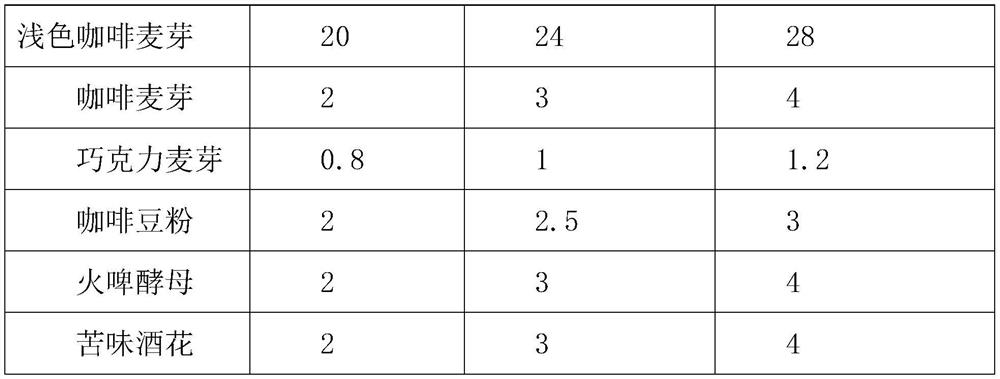

Embodiment 1

[0024] A kind of hot beer that can be heated and consumed in ice, the formula of the hot beer that can be heated and consumed in ice is as follows: (according to 2 tons of saccharification) 200kg of light-colored malt, 5kg of wheat malt, 6kg of caramel malt, 28kg of crystallization, Red malt 10kg, light coffee malt 20kg, coffee malt 2kg, chocolate malt 0.8kg, coffee bean powder 2kg, fire brewer's yeast 2kg, bitter hops 2kg.

[0025] A process for preparing a hot beer that can be heated and refrigerated for drinking, comprising the following steps:

[0026] S1. Raw material selection: light-colored malt, wheat malt, caramel malt, crystal, red malt, light-colored coffee malt, coffee malt, chocolate malt, coffee bean powder, fire brewer's yeast, bitter hops;

[0027] S2. Crushing of raw materials, using pair of rollers, the distance between the rollers is 0.25-0.35mm, moisturizing and crushing light-colored malt, wheat malt, caramel malt, crystal, red malt and light-colored coffe...

Embodiment 2

[0038] A kind of hot beer that can be heated and consumed cold, the formula of the hot beer that can be heated and consumed cold is as follows: (according to 2 tons of saccharification) 220kg of light-colored malt, 5.8kg of wheat malt, 8kg of caramel malt, 34kg of crystallization , red malt 15kg, light coffee malt 24kg, coffee malt 3kg, chocolate malt 1kg, coffee bean powder 2.5kg, fire brewer's yeast 3kg, bitter hops 3kg.

[0039] A process for preparing a hot beer that can be heated and refrigerated for drinking, comprising the following steps:

[0040] S1. Raw material selection: light-colored malt, wheat malt, caramel malt, crystal, red malt, light-colored coffee malt, coffee malt, chocolate malt, coffee bean powder, fire brewer's yeast, bitter hops;

[0041] S2. Crushing of raw materials, using pair of rollers, the distance between the rollers is 0.25-0.35mm, moisturizing and crushing light-colored malt, wheat malt, caramel malt, crystal, red malt and light-colored coffee...

Embodiment 3

[0052] A kind of fire beer that can be heated and drunk coldly, the formula of the fire beer that can be heated and drunk coldly is as follows: (based on 2 tons of saccharification) 240kg of light-colored malt, 6.8kg of wheat malt, 10kg of caramel malt, and 40kg of crystallization , Red malt 20kg, light coffee malt 28kg, coffee malt 4kg, chocolate malt 1.2kg, coffee bean powder 3kg, fire beer yeast 4kg, bitter hops 4kg.

[0053] A kind of preparation technology of the fire beer that can be heated, iced to drink, comprises the following steps:

[0054] S1. Selection of raw materials: light-colored malt, wheat malt, caramel malt, crystallization, red malt, light-colored coffee malt, coffee malt, chocolate malt, coffee bean powder, fire beer yeast, bitter hops;

[0055] S2. Raw materials are crushed by pair of rollers, the distance between the rollers is 0.25-0.35mm, light-colored malt, wheat malt, caramel malt, crystallization, red malt and light-colored coffee malt are humidifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com