Preparation method and application of a novel hydrocarbon fuel coking inhibitor

A technology of coking inhibitor and hydrocarbon fuel, which is applied in fuel additives, liquid carbon-containing fuels, fuels, etc., can solve problems affecting the strength and toughness of matrix materials, and achieve high-temperature coking, avoid pollution, and ensure long-term stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A novel hydrocarbon fuel coking inhibitor comprises glycerol with a mass fraction of 15% to 25%, hydroxyl-terminated hyperbranched polyester (HBP) with a mass fraction of 5% to 15%, and deionized water with a mass fraction of 70%.

[0025] Preferably, a novel hydrocarbon fuel coking inhibitor comprises 15% by mass of glycerol, 15% by mass of hydroxyl-terminated hyperbranched polyester (HBP) and 70% by mass of deionized water.

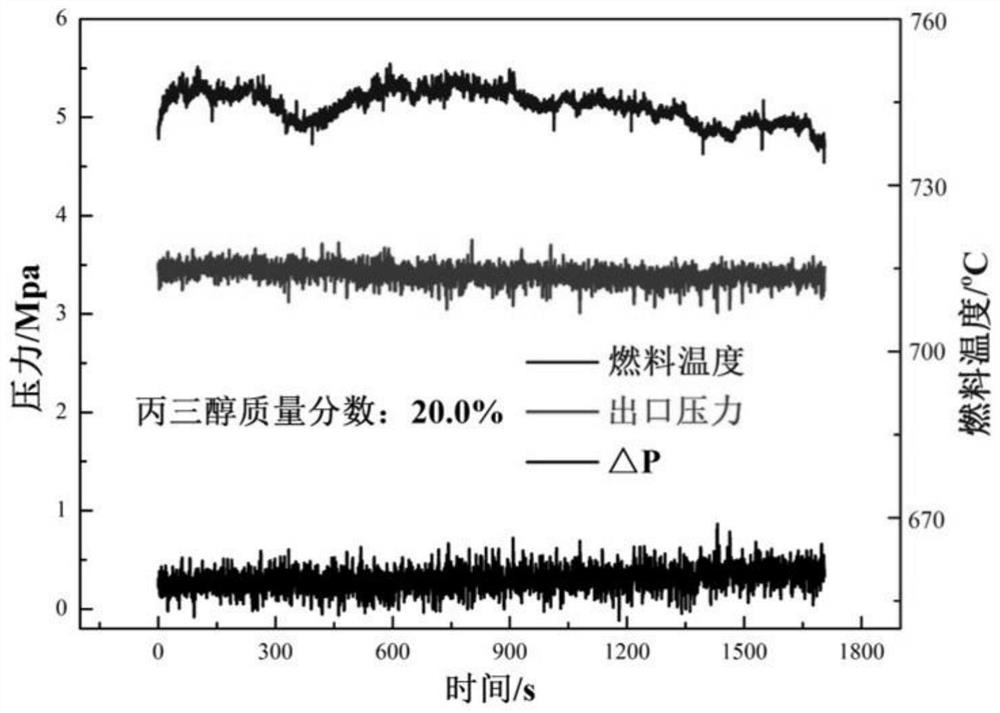

[0026] Preferably, a novel hydrocarbon fuel coking inhibitor comprises 20% by mass of glycerol, 10% by mass of hydroxyl-terminated hyperbranched polyester (HBP) and 70% by mass of deionized water.

[0027] Preferably, a novel hydrocarbon fuel coking inhibitor comprises 25% by mass of glycerol, 5% by mass of hydroxyl-terminated hyperbranched polyester (HBP) and 70% by mass of deionized water.

Embodiment 2

[0029] A preparation method of a novel hydrocarbon fuel coking inhibitor, the preparation method is realized by the following steps:

[0030] S1. Weigh deionized water with a mass fraction of 70% with an analytical balance, add glycerol with a mass fraction of 15% to 25% into the deionized water, and slowly stir with a glass rod for 10 minutes;

[0031] S2, add the mass fraction of 5% to 15% hydroxyl-terminated hyperbranched polyester (HBP) into the solution, and continue to stir slowly for 10min;

[0032] S3. Put the mixed solution into an ultrasonic cleaner and shake for 30 minutes to ensure that the solution is mixed evenly, and the solution is sealed and stored.

Embodiment 3

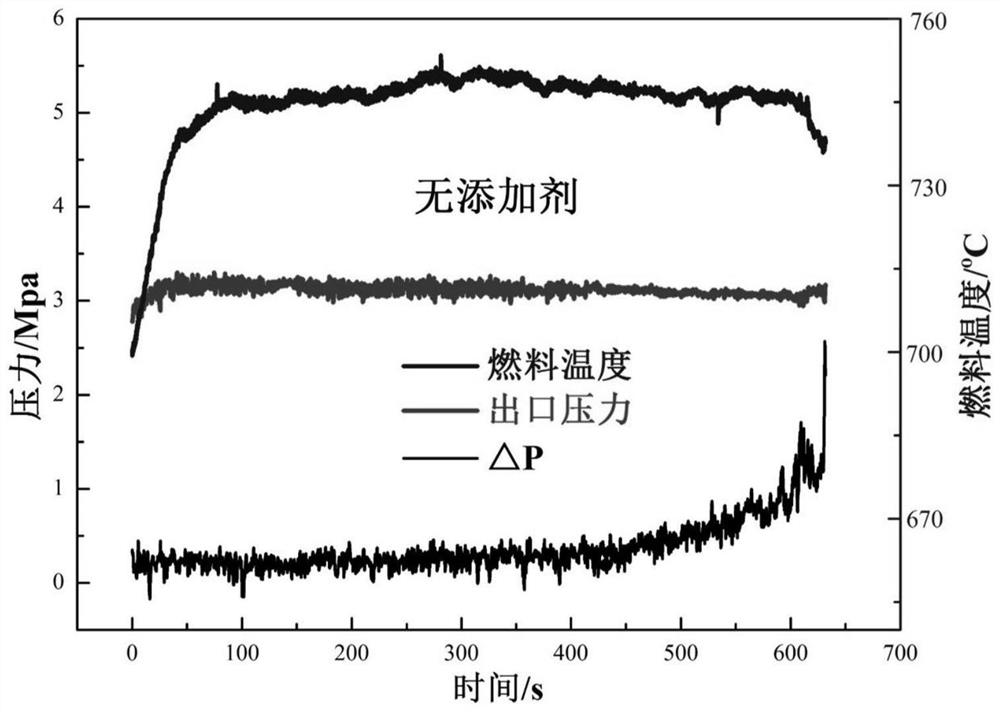

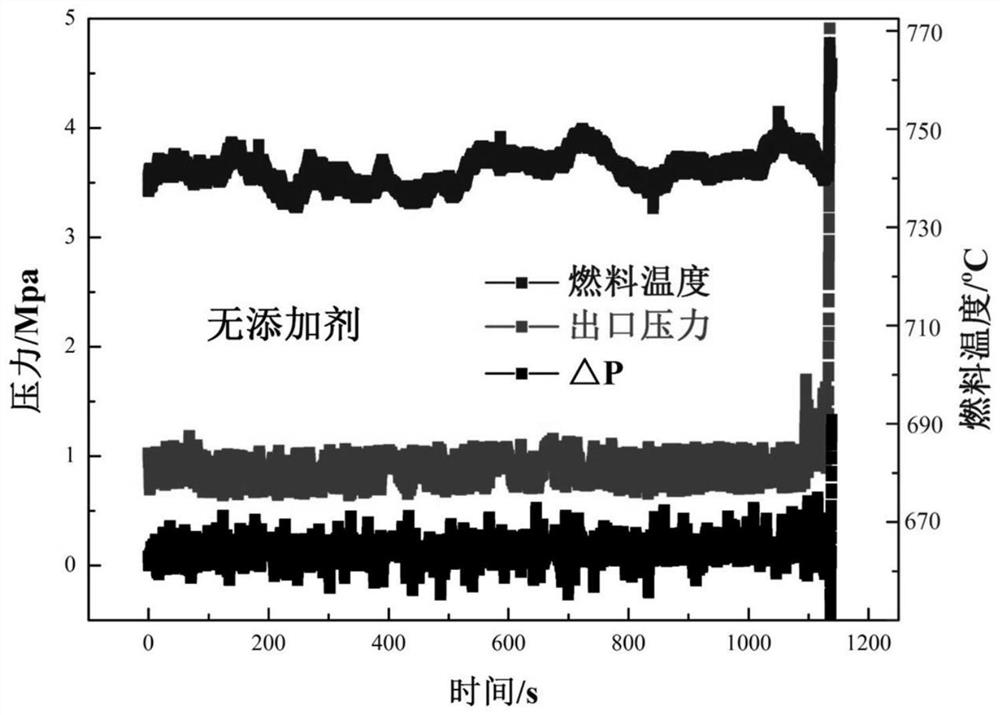

[0034] The application of a novel hydrocarbon fuel coking inhibitor is specifically realized by the following method: a tee joint is arranged at the inlet of a high-temperature fuel cracking device of an aerospace power engine, and the fuel and the coking inhibitor are respectively added from two channels. The branch of the coking inhibitor is equipped with an electronic valve. The valve is automatically closed when the fuel cracking temperature is lower than 700 °C, and the valve is automatically opened when the fuel cracking temperature is higher than 700 °C. The coking inhibitor is added to the cracking device. Barbed wire, increasing the heat flow disturbance can ensure that the fuel and additives are mixed evenly, and the addition amount of the coking inhibitor is 5% of the fuel amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com