Device for carrying out molding pin arrangement on inductor

A technology of inductors and forming mechanisms, which is used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of difficulty in inserting the copper wire of the PIN pin of the inductor, high cost, and difficulty at the bottom of the magnetic core. The effect of smooth tangent, good forming consistency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

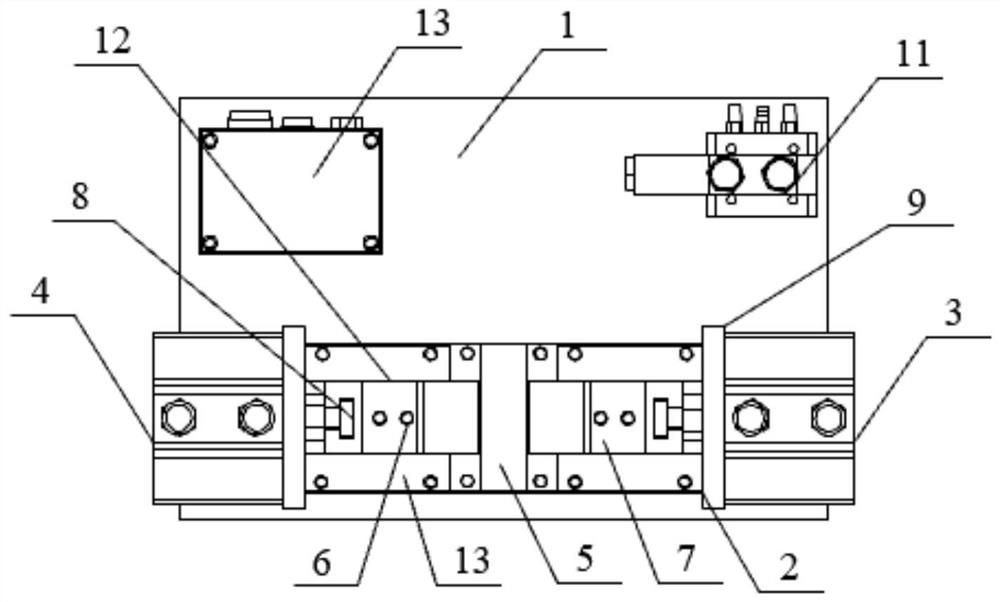

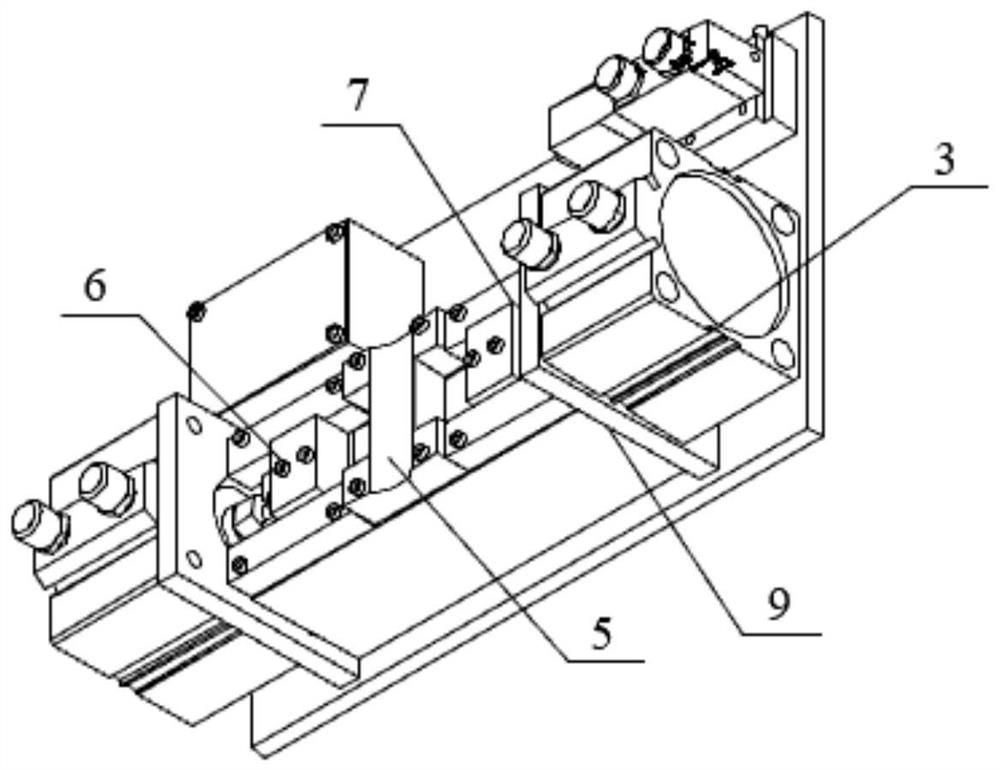

[0019] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a device for forming and trimming inductors, including a mounting base 1, on which a cutting leg forming mechanism 2, an electric control switch box 14 and a pneumatic control valve 11 are arranged. The first cylinder 3 and the second cylinder 4 are arranged on both sides of the shearing foot forming mechanism 2, and the first cylinder 3, the second cylinder 4, and the pneumatic control valve 11 are all electrically connected with the electric control switch box 14.

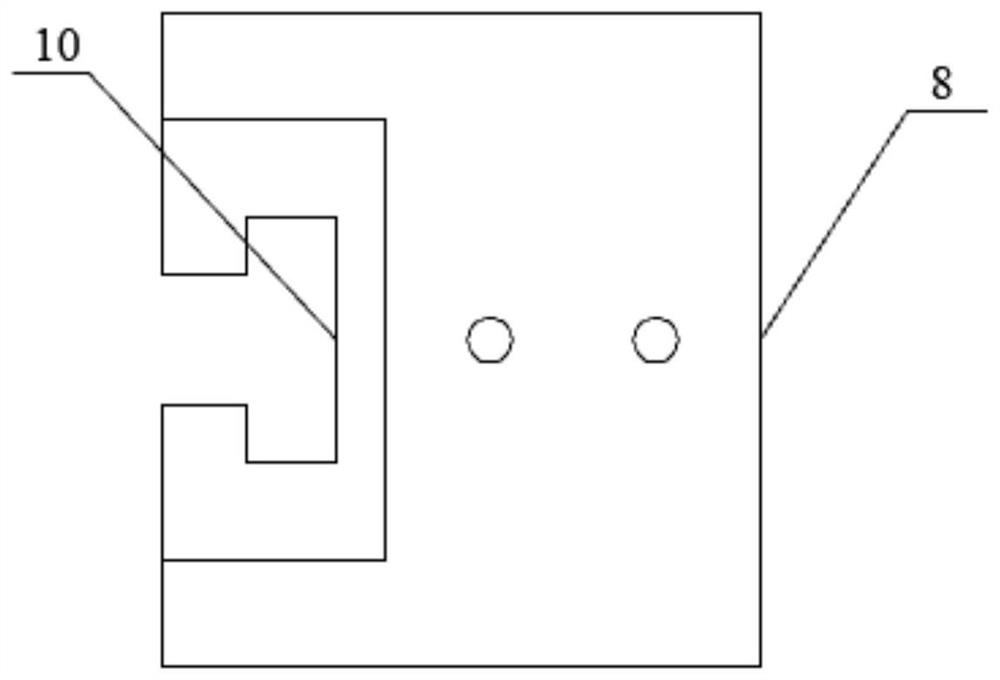

[0020] The shearing foot molding mechanism 2 comprises a magnetic core accommodation area 5, a first molding briquetting block 6 and a second molding briquetting block 7, and the first molding briquetting block 6 and the second molding briquetting block 7 are distributed on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com