Heat supply system of fuel gas-steam combined cycle thermal power plant

A combined cycle and heating system technology, applied in steam central heating systems, heating systems, steam superheating, etc., can solve the problem of not effectively utilizing waste heat boiler steam, etc., to achieve easy adjustment, simple equipment settings, and realization of thermoelectricity The effect of decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

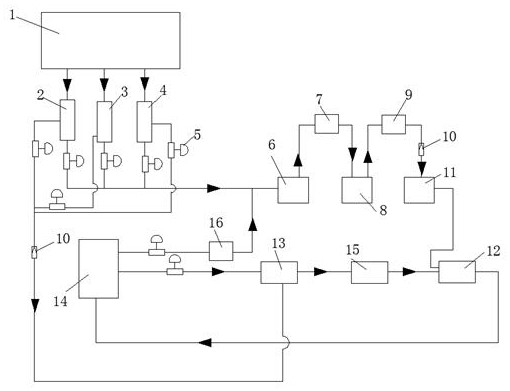

[0018] see figure 1 ,

[0019] A heat supply system of a gas-steam combined cycle thermal power plant, including a steam drum, a first superheater, a second superheater, a third superheater, a high-pressure cylinder, a medium-pressure cylinder, a low-pressure cylinder, a first heat exchanger, a second Heat exchanger, third heat exchanger, first reheater, second reheater, third reheater, waste heat boiler;

[0020] The steam drum 1 is respectively connected to the first superheater 2, the second superheater 3, and the third superheater 4, and the first superheater 2, the second superheater 3, and the third superheater 4 pass through the electronic flow valve 5 and the high-pressure cylinder 6 respectively. The high-pressure cylinder 6 is connected to the first reheater 7 through the electronic flow valve 5, the first reheater 7 is connected to the medium-pressure cylinder 8, and the medium-pressure cylinder 8 is connected to the second reheater 9 through the electronic flow va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com