Hole plugging device and process for honeycomb ceramic carrier for tail gas purification of thin-wall diesel engine

A honeycomb ceramic carrier and exhaust gas purification technology, which is used in mechanical equipment, exhaust devices, engine components, etc., can solve problems such as easy displacement of plugging and extrusion, uneven surface of product batches, and inconvenient adjustment of plugging depth. , to reduce the unevenness of the pressing surface, reduce the unevenness of the surface, and protect the ceramic carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

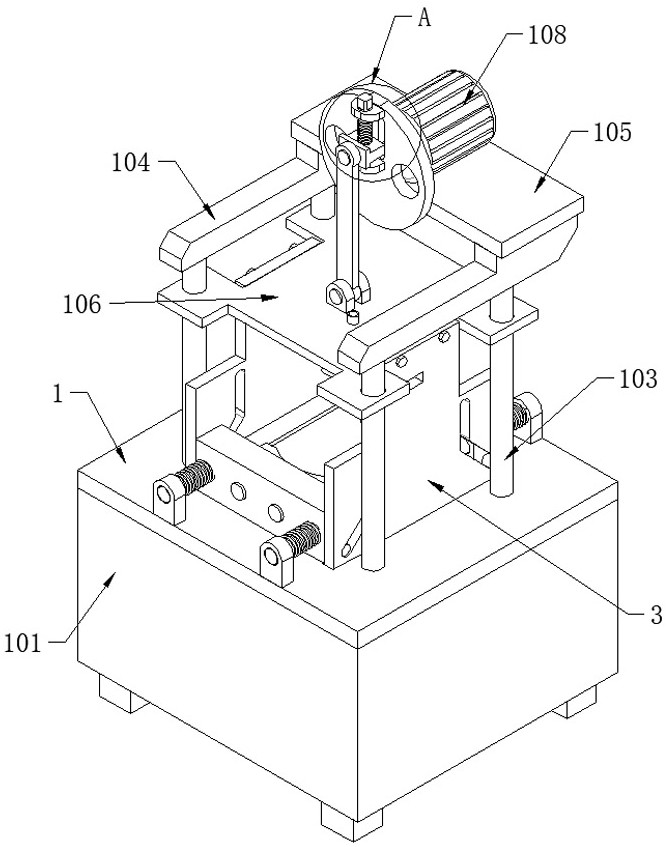

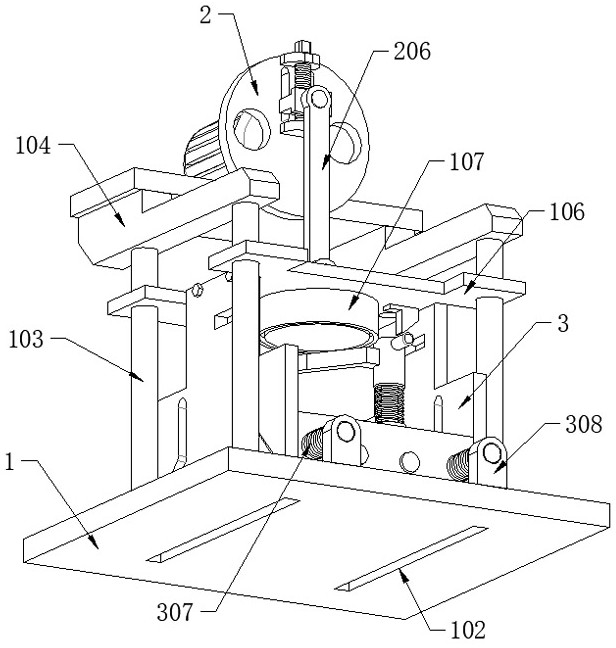

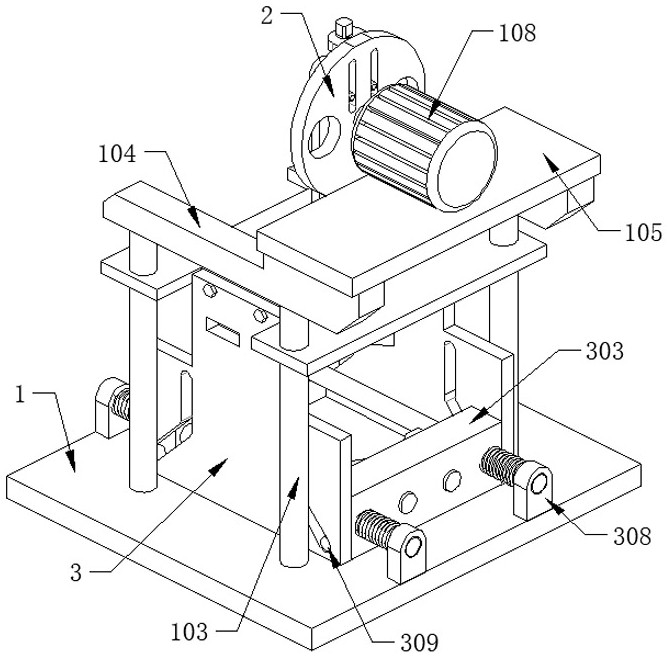

[0038] refer to Figure 1-8 , a honeycomb ceramic carrier plugging device for thin-walled diesel engine exhaust gas purification, including a base 1, a box body 101 and four sets of sliding columns 103, the base 1 is connected to the top wall of the box body 101, and the four sets of sliding columns 103 are all connected to the top wall of the base 1 The outer walls of four groups of sliding columns 103 are slidingly connected with lifting plates 106, the bottom walls of lifting plates 106 are connected with compression molds 107, the top walls of two adjacent groups of sliding columns 103 are connected with connecting blocks 104, and the top walls of two groups of connecting blocks 104 are connected with Connecting plate 105, the top wall of the connecting plate 105 is connected with a power assembly, the output end of the power assembly is connected to the top wall of the lifting plate 106, the bottom wall of the lifting plate 106 is connected to the limiting assembly, the to...

Embodiment 2

[0043] refer to Figure 1-8 , the limiting assembly includes a limiting plate 3 and a sliding rod 306, the top wall of the base 1 is provided with a through groove 102, the limiting plate 3 is connected to the side wall of the lifting plate 106, the limiting plate 3 is matched with the through groove 102, and the sliding rod 306 Both ends are connected with a fixing seat 308, and the fixing seat 308 is connected to the top wall of the base 1, and two groups of the limiting plate 3 and the sliding rod 306 are arranged symmetrically.

[0044] The outer walls of two groups of sliding rods 306 are slidably connected with two groups of sliding blocks 303, the side walls on both sides of the two groups of sliding blocks 303 are connected with limiting rods 309, and the inner walls of the two groups of limiting plates 3 are provided with first limiting grooves 301 and second As for the limiting groove, the two sets of sliding blocks 303 are respectively matched with the first limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com