Variable valve distribution camshaft of engine

A technology for engines and camshafts, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as unsatisfactory, high cost, and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

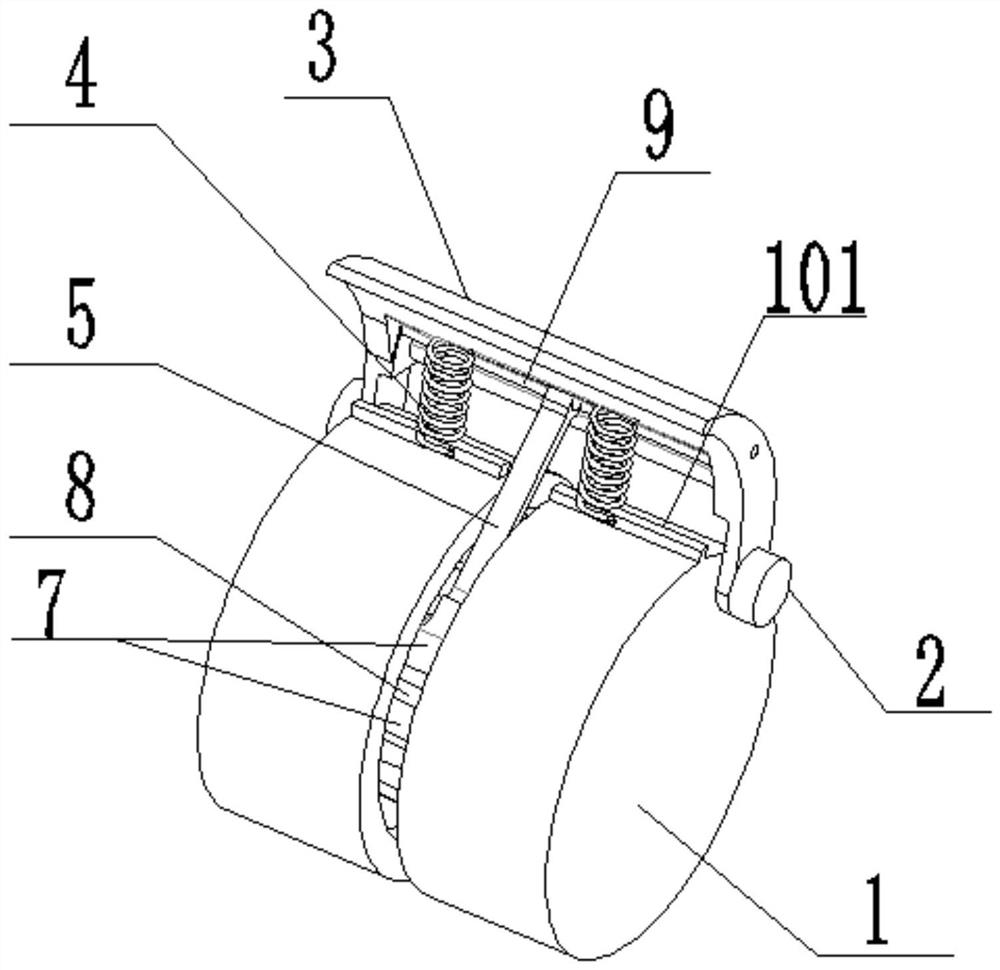

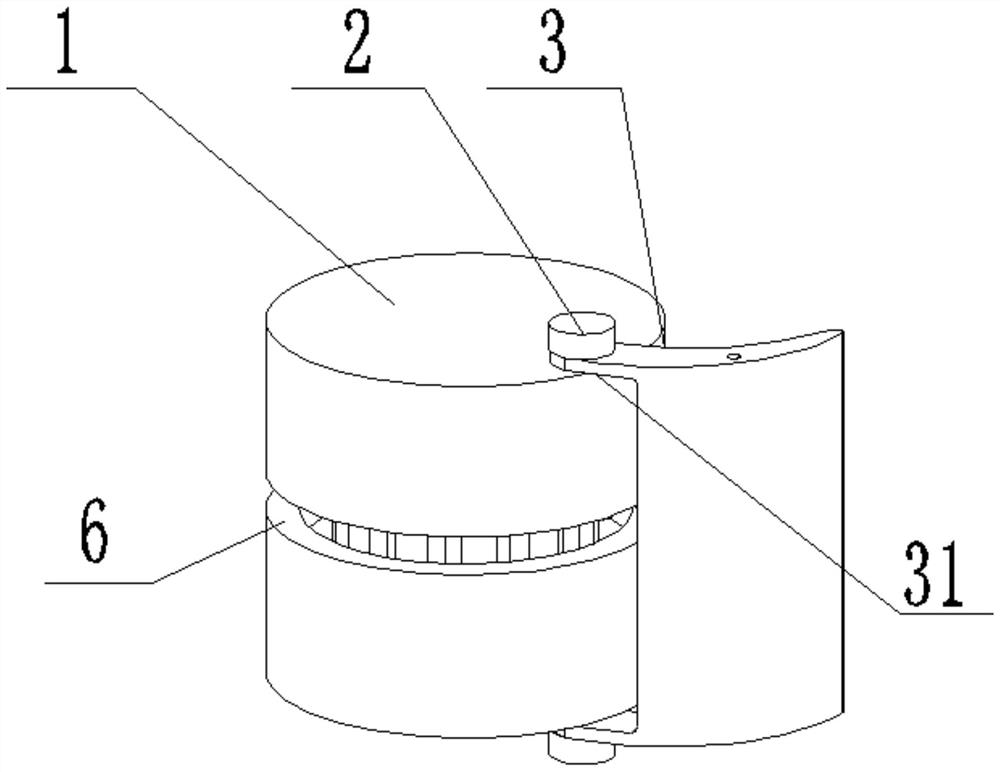

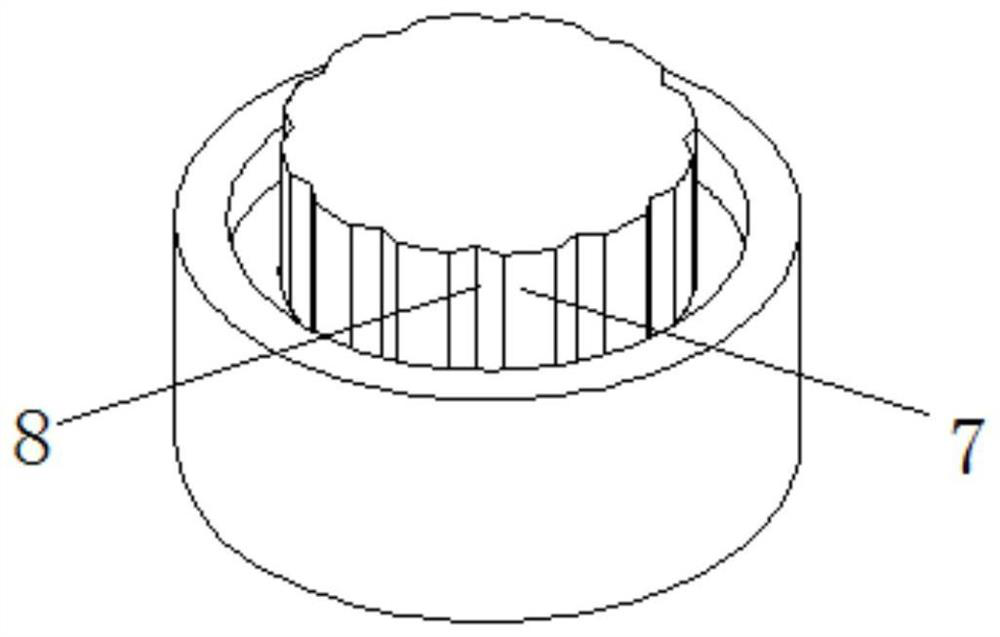

[0014] like Figure 1-Figure 3 As shown, a variable valve camshaft for an engine in this embodiment includes a cylindrical shaft 1, a fan-shaped steel plate 3, a spring 4, and a T-shaped connector 5. The outer wall of the cylindrical shaft 1 is provided with a circle along the circumference. An inverted T-shaped annular groove 6 has several ribs 7 evenly distributed axially along the cylinder axis, and axial grooves 8 are formed between two adjacent ribs 7; the upper and lower ends of the arc-shaped steel plate 3 are both The connecting plate 31 is fixedly connected, and the connecting plate 31 at the upper end and the lower end of the arc-shaped steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com