Automatic painting and slotting equipment for indoor basketball court floor

A technology for slotting equipment and basketball courts, which can be applied to buildings, floors, coatings, etc., and can solve problems such as reducing work efficiency, consuming manpower, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

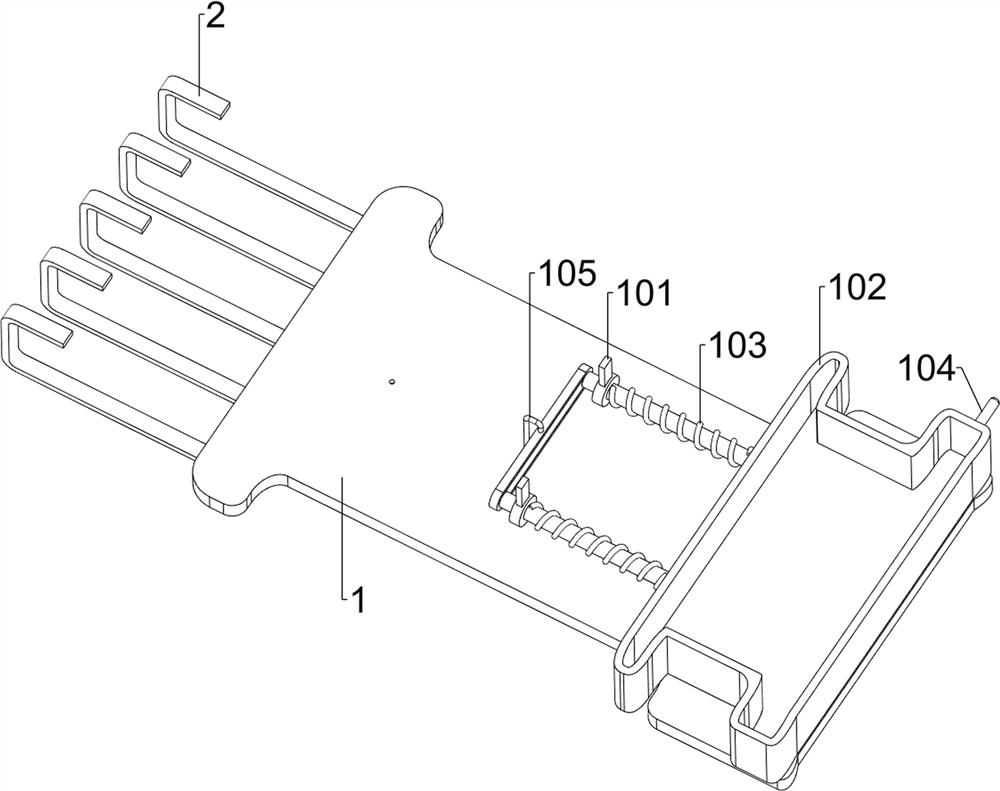

[0070] An indoor basketball court floor automatic painting groove equipment, such as figure 1 As shown, it includes a first support plate 1, a first support frame 2, a second support plate 3, a hand pushing mechanism 4, a fork lowering mechanism 5, a painting mechanism 6, a paint weighting mechanism 7 and a triangular slotting mechanism 8 , the left part of the first support plate 1 is evenly provided with five first support frames 2, the second support plate 3 is connected between the right parts of the five first support frames 2, and the second support plate 3 is provided with a push mechanism 4 , the hand push mechanism 4 is provided with a bifurcated lowering mechanism 5, the lower side of the bifurcated lowering mechanism 5 is provided with a painting mechanism 6, the left part of the hand pushed mechanism 4 is provided with a paint weighting mechanism 7, and the upper right side of the bifurcated lowering mechanism 5 A triangular slotting mechanism 8 is provided.

[00...

Embodiment 2

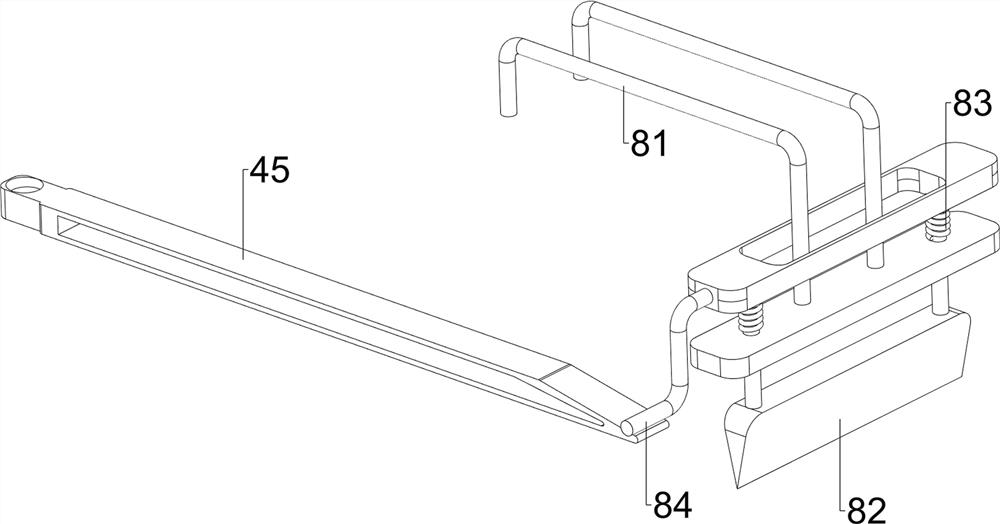

[0073] On the basis of Example 1, such as Figure 2-6 As shown, the hand pushing mechanism 4 includes a second support frame 41, a pusher 42, a handle 43, a first spring 44, a long board frame 45, a third support plate 46 and a plug 47, and on the second support plate 3 The right side is provided with a second support frame 41, and a pusher 42 is slidingly provided between the front and rear sides of the second support frame 41, and a first spring 44 is connected between the front and rear sides of the pusher 42 and the second support frame 41, The first spring 44 is wound on the pusher 42, the front portion of the pusher 42 is provided with a handrail 43, the right side of the front portion of the pusher 42 is provided with a long plate frame 45, and a third support is connected between the front and rear sides of the pusher 42. The plate 46 and the third supporting plate 46 are provided with an inserting block 47 .

[0074] After people put two floorboards on the second sup...

Embodiment 3

[0084] On the basis of Example 2, such as Figure 7 and Figure 8 As shown, a drying mechanism 9 is also included, and the drying mechanism 9 includes a sixth support frame 91, a motor 92, a fan 93 and a seventh support rod 94, and the upper right side of the upper part of the board 52 is provided with a sixth support frame 91, Motor 92 is installed on the 6th bracing frame 91, is connected with fan 93 on the output shaft of motor 92, and fan 93 left side front and rear sides are all provided with the seventh support rod 94, and the seventh support rod 94 of front and back both sides is all connected with the fifth. The support frame 81 is connected.

[0085] When people move the handrail 43 to the right and start the motor 92, the output shaft of the motor 92 rotates to drive the fan 93 to rotate, thereby drying the painted floor, which realizes the effect of the fan 93 drying the floor. When there is no floor on the second support plate 3, people close the motor 92.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com