Gas permeation type textile printing and dyeing process

A technology of textile printing and dyeing and air infiltration, applied in the textile field, can solve the problems of reducing the amount of liquid in the fabric, reducing the color fixing effect, etc., and achieve the effect of improving the dyeing effect, simplifying the drying and color fixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

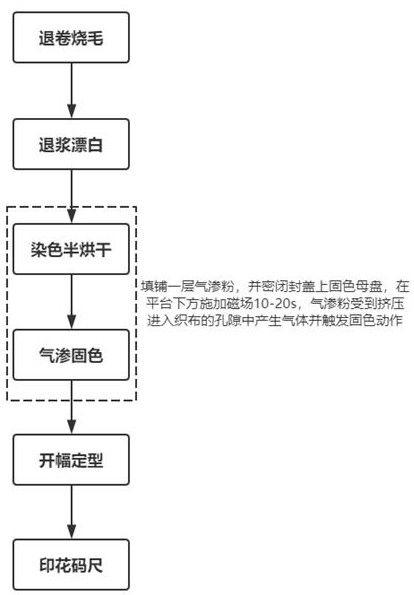

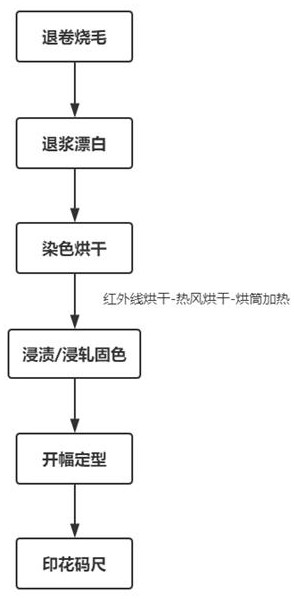

[0045] see figure 1 , an air-permeable textile printing and dyeing process, comprising the following steps:

[0046] S1. Take the woven fabric and install it on the unwinding machine for unwinding, and then send it through the singeing machine to complete the singeing process;

[0047] S2. Carry out desizing treatment to the woven fabric, then wash with water and carry out scouring and bleaching to remove residual size and impurities, and dry for later use;

[0048] S3. Dye the dried fabric by padding in the dye vat prepared with the dye solution. The bath ratio is 1:15, and it is treated at 60°C for 10 minutes, so that the liquid-carrying rate of the fabric reaches 80-90%, and then infrared rays are used. The method of drying reduces the liquid-carrying rate of the fabric to less than 50%;

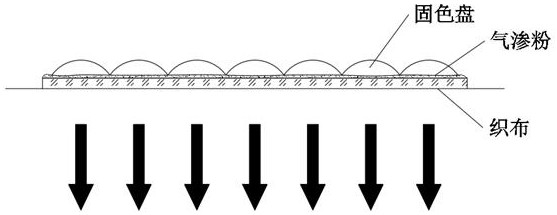

[0049] S4. Unfold and spread the fabric onto the platform, then fill with a layer of air permeation powder, seal and cover the solid color master plate, apply a magnetic field under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com