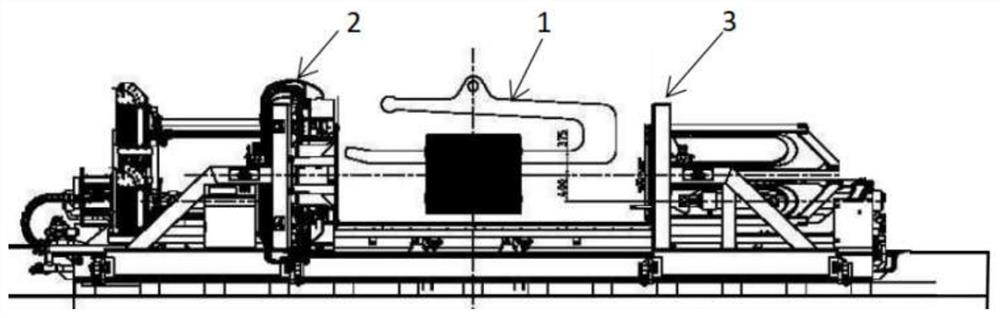

Wire coil bundling angle bead filling anti-scratch device and bundling method

A corner protection and coiling technology, which is applied in the direction of bundling objects, packaging/bundling articles, and parts of bundling machinery, can solve the problems of difficult further improvement of production efficiency, poor effect, and limited effect of eliminating scratches, etc., to achieve Obvious social and economic benefits, improved deep processing efficiency, and low application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for bundling the above-mentioned wire coil bundling corner protection filling anti-scratch device, the specific steps are:

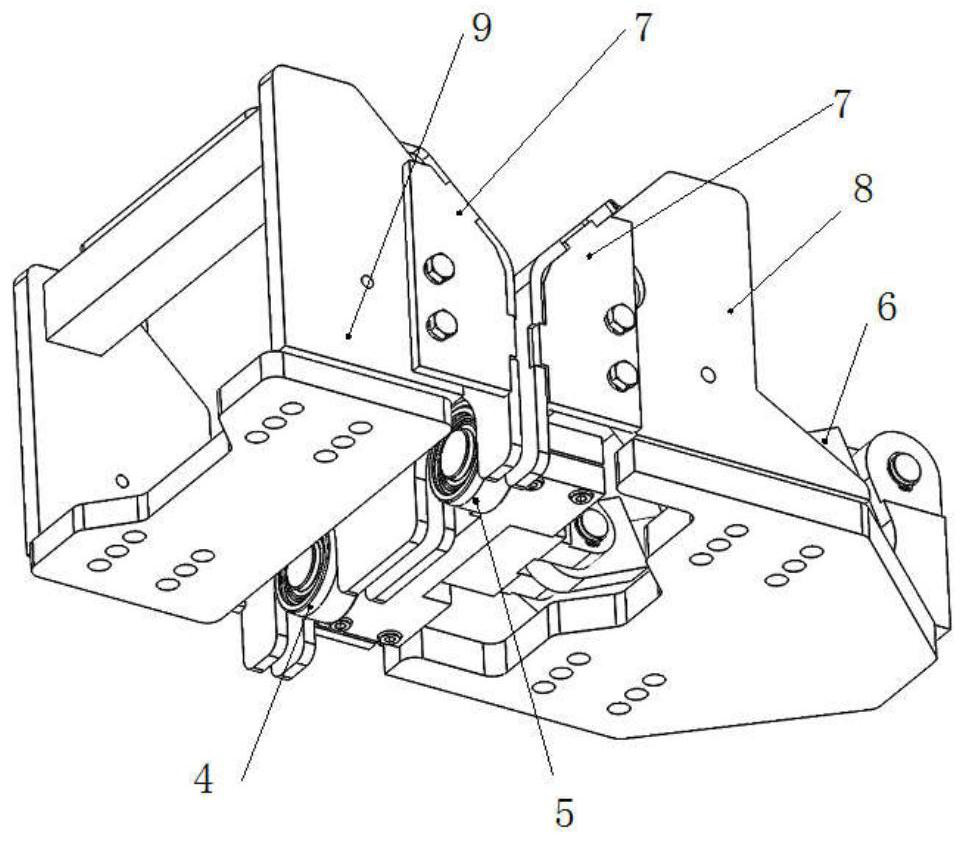

[0064] (1) Filling and consumption of metal sheets for corner protection of storage box

[0065] On the main vertical plates on both sides of the pressure plate of the baler platen car, multiple sets of storage boxes are independently installed, and four storage boxes 11 are optionally provided, corresponding to the tightening parts of the four bundles respectively. The storage boxes 11 The interior is filled with corner protector metal sheets 15, and the number of corner protector metal sheets 15 in the material storage box 11 is not less than 150 pieces at a time. By counting the materials, the corner protector metal sheets in the cavity structure of the material storage box 11 15 consumptions are counted, and each time it is used, one piece is consumed and separated; when the usage quantity is lower than the set minimum value, directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com