Ultra-long thin-wall hydraulic bolt sleeve

A hydraulic bolt and sleeve technology, applied in the field of sleeve processing solutions, can solve the problems of inconvenient access, high price, and impracticality, and achieve the effects of easy disassembly and storage, convenient installation and disassembly, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

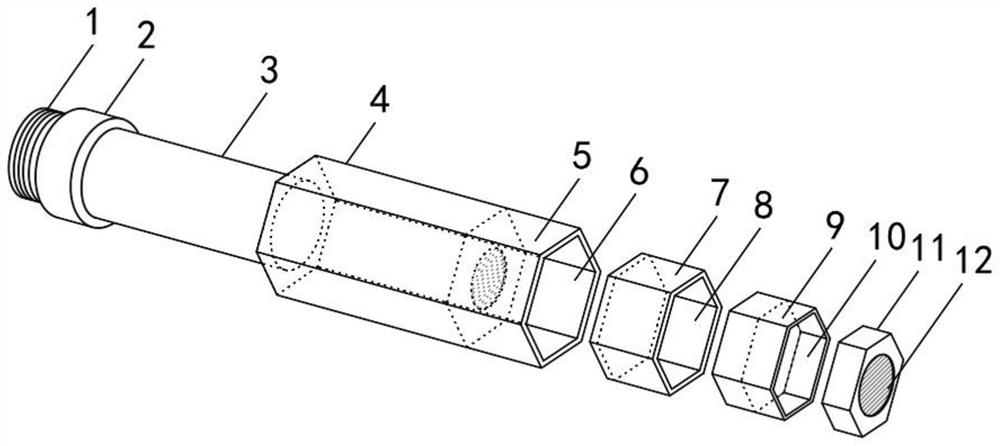

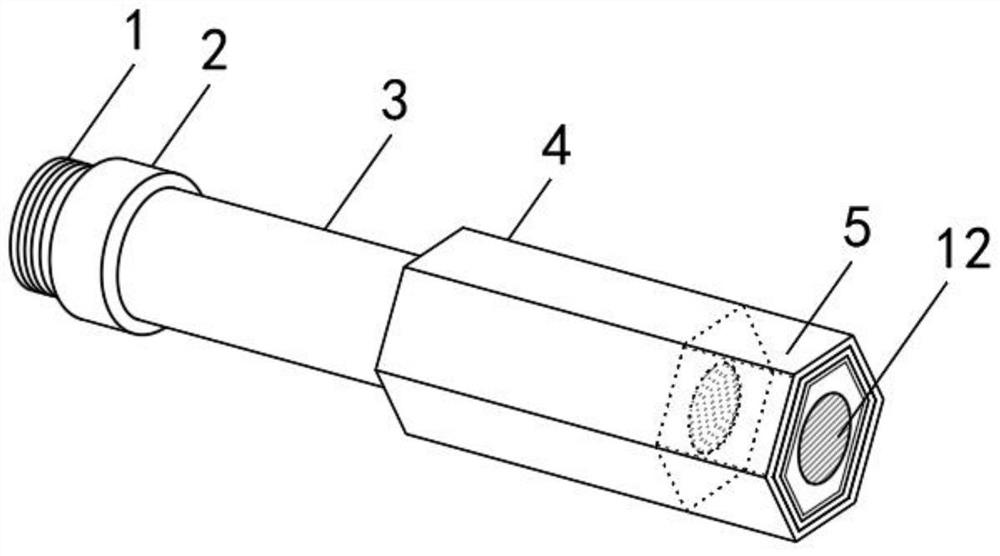

[0016] Such as Figure 1-2 As shown, the ultra-long thin-wall hydraulic bolt sleeve includes an ultra-long thin-wall hydraulic bolt sleeve, and the ultra-long thin-wall hydraulic bolt sleeve includes a main bolt sleeve 4, a No. 1 auxiliary sleeve 7, and a No. 2 auxiliary sleeve 9 And No. 3 auxiliary sleeve 11, one side of the main bolt sleeve 4 is connected to the extension rod 3, and the end of the extension rod 3 is provided with a hydraulic bolt sleeve installation thread 1, and one side of the hydraulic bolt sleeve installation thread 1 is located on the outside of the extension rod 3. Install the limit ring 2, the other side of the main bolt sleeve 4 is provided with a main installation port 6, and one side of the main installation port 6 is located inside the extension rod 3. There is a main sleeve function slot 5, and the main sleeve function slot 5 There is a No. 1 auxiliary sleeve 7, and the No. 1 auxiliary sleeve 7 is provided with a No. 1 sleeve function slot 8 insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com