Four axle moving tank for high speed rice seedling planter

A rice transplanter and rice technology, which is applied in the field of high-speed rice transplanter four-axis shifting box, can solve the problem of inability to meet the performance requirements of high-speed rice transplanter, and achieve the effect of reducing power transmission distance, reducing cam wear, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

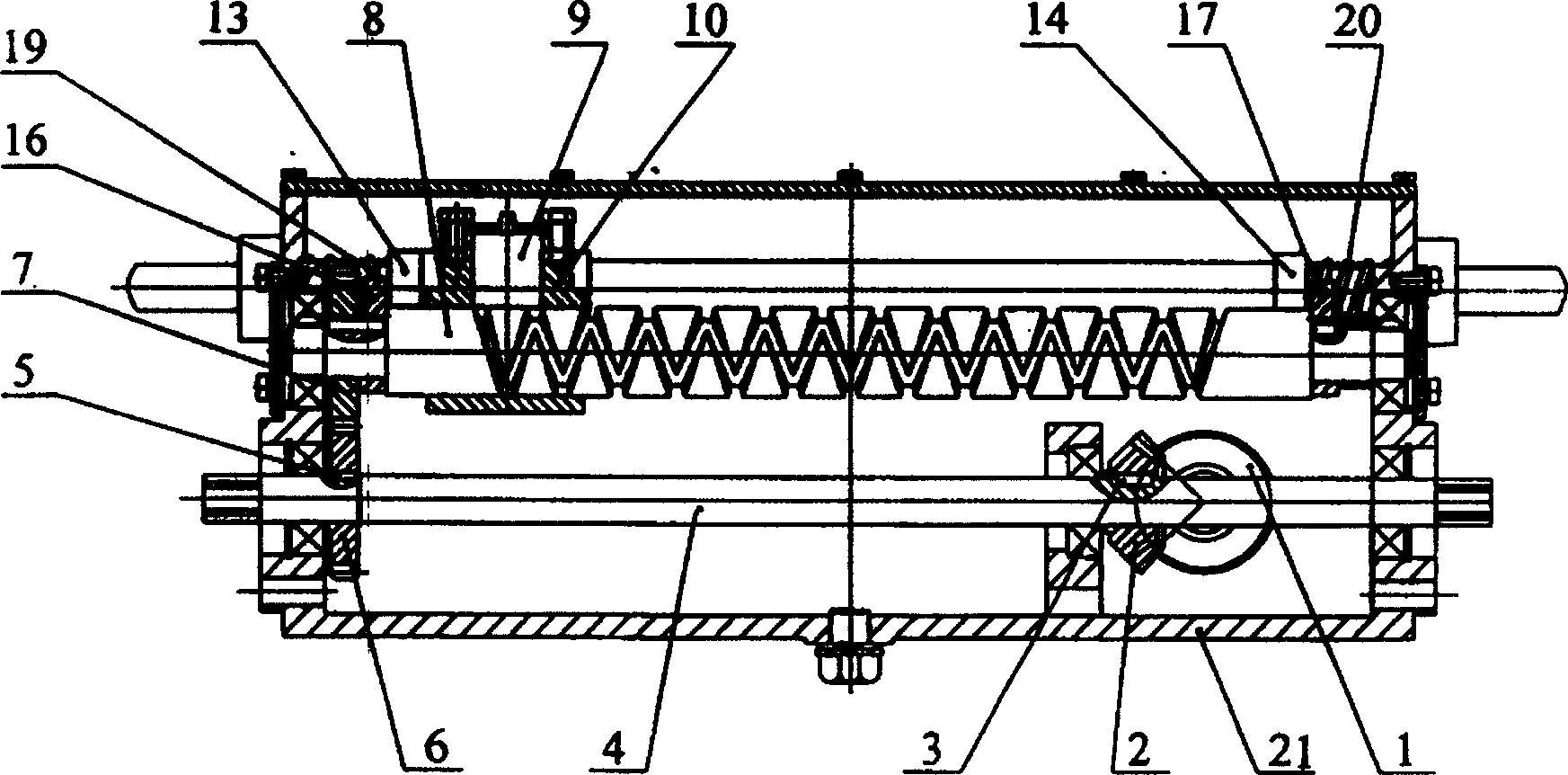

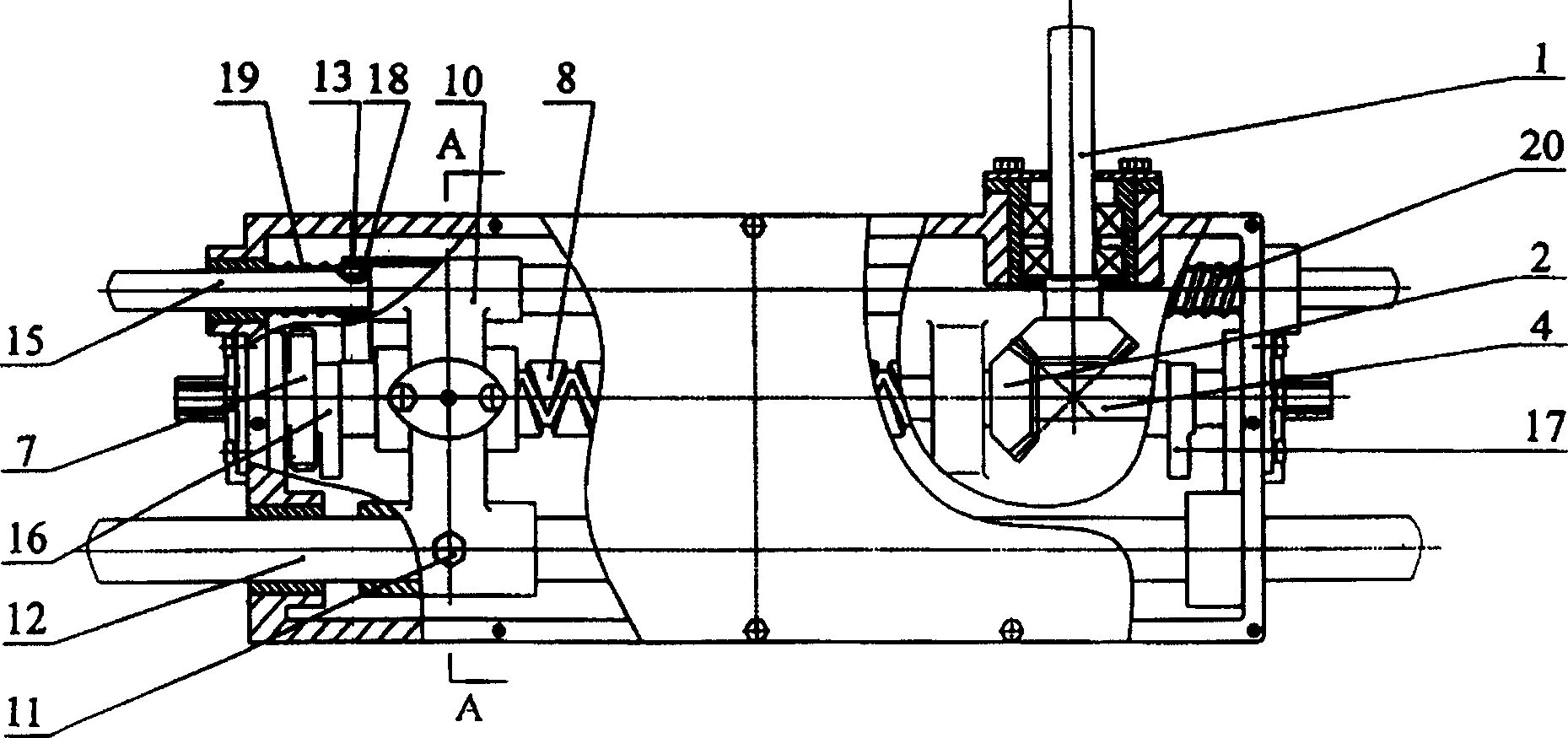

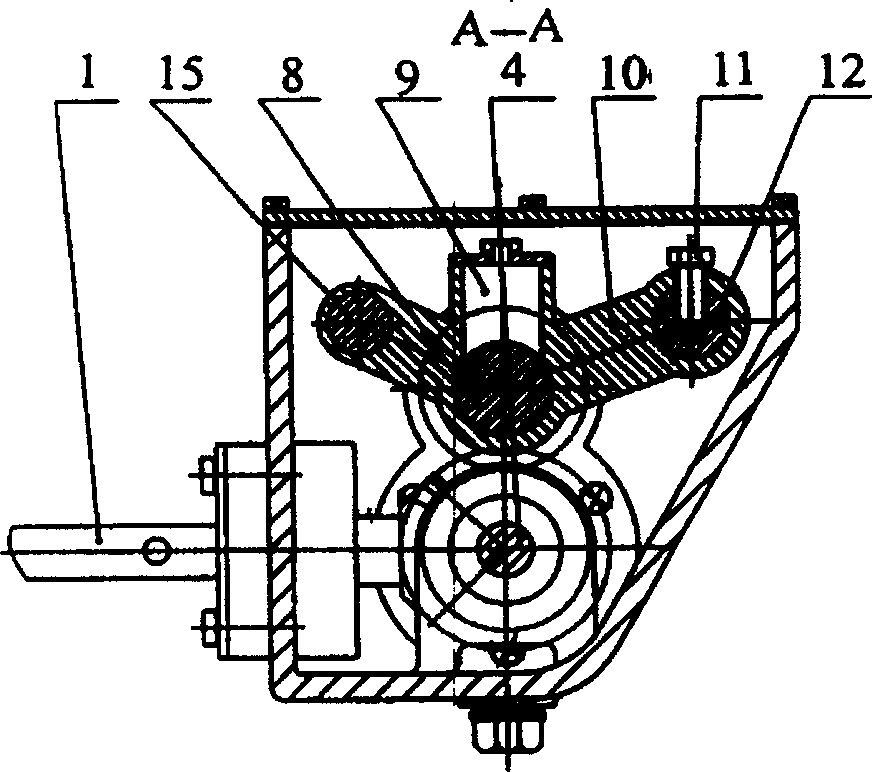

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, after the power is output from the gearbox, it is connected with the power input shaft 1 of the box-moving box to realize the connection of power. In the moving box body 21, the power input shaft 1 is connected with the bevel gear 2 to complete the power steering, the power changes from longitudinal to horizontal rotation, and the power is directly transmitted to the splitting mechanism through the bevel gear 2, key 3 and transmission shaft 4 all the way; One way is to transfer the power from the transmission shaft 4 to the screw shaft 8 through the key 5 and a pair of gears 6 and 7; The shaft 12 is connected with the seedling box to realize the horizontal seedling delivery power output; at the same time, through the reciprocating movement of the sliding sleeve 10, the left and right swing rods 13 and 14 are pushed to move along the seedling delivery shaft 15 respectively at the rotary track at both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com