Scrap iron cleaning equipment for machining factory

A technology for cleaning equipment and processing plants, applied to cleaning equipment, cleaning machinery, manual sweeping machinery, etc., can solve the problems of low efficiency of iron scrap cleaning, reduced work efficiency, and increased labor intensity of operators, so as to achieve high work efficiency and easy operation. Simple, convenient and efficient cleaning of iron filings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

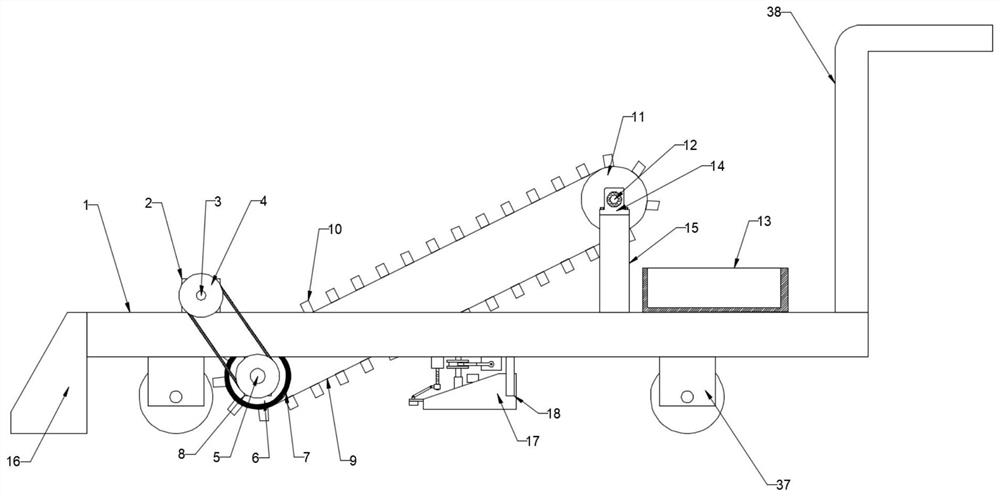

[0026] see Figure 1~4 , in an embodiment of the present invention, a scrap iron chip cleaning device used in a mechanical processing plant includes a base 1, the base 1 is provided with a primary cleaning mechanism, the primary cleaning mechanism includes a first motor 2, and the first A motor 2 is provided with a first transmission shaft 3, the lower part of the first transmission shaft 3 is provided with a first driven shaft 5, and the first driven shaft 5 is connected to the lower end surface of the base 1 through a first mounting plate 8, The first driven shaft 5 is provided with a main drive roller 6, and the first driven shaft 3 and the first driven shaft 5 are respectively provided with a pulley 4, and the two pulleys 4 are connected by a belt, so The main drive roller 6 is sleeved with an annular magnet 7, and one side of the first driven shaft 5 is provided with a second driven shaft 12, and the second driven shaft 12 is provided with a driven roller 11, and the driv...

Embodiment 2

[0028] see Figure 5The difference between this embodiment of the present invention and Embodiment 1 is that a secondary cleaning mechanism is provided on the lower end surface of the base 1, and the secondary cleaning mechanism includes a second collection frame 17, a second motor 19 and a third motor 20 , the second collection frame 17 is provided with a third mounting plate 18, and the upper end of the third mounting plate 18 is fixedly connected with the base 1, the second motor 19 is provided with a second transmission shaft 21, and the second transmission The shaft 21 is provided with a toggle block 23, and one side of the second motor 19 is provided with a connecting shaft 24, and the upper end of the connecting shaft 24 is fixedly connected with the lower end surface of the base 1, and the connecting shaft 24 is provided with a sliding sleeve 26 , the upper part of the sliding sleeve 26 is provided with a toggle wheel 25, and the toggle wheel 25 is provided with a groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com