Rumen bypass amino acid and preparation method thereof

An amino acid and rumen-passing technology, which is applied in the field of rumen-passing amino acids and their preparation, can solve problems such as threats to the health of ruminants and humans, affecting the industrialization process, and complicated mass production processes, and achieve good rumen-passing protection ability and good rumen-passing ability, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

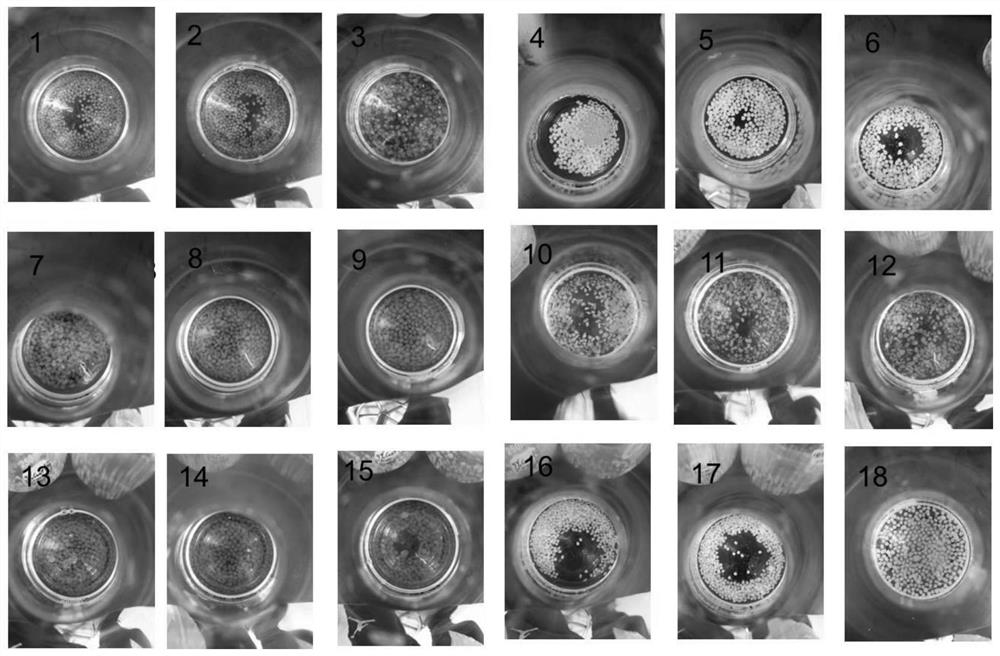

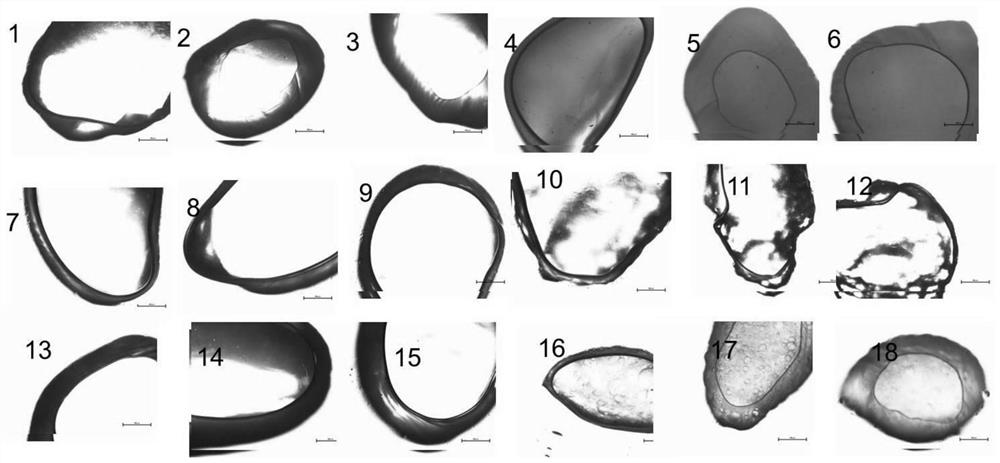

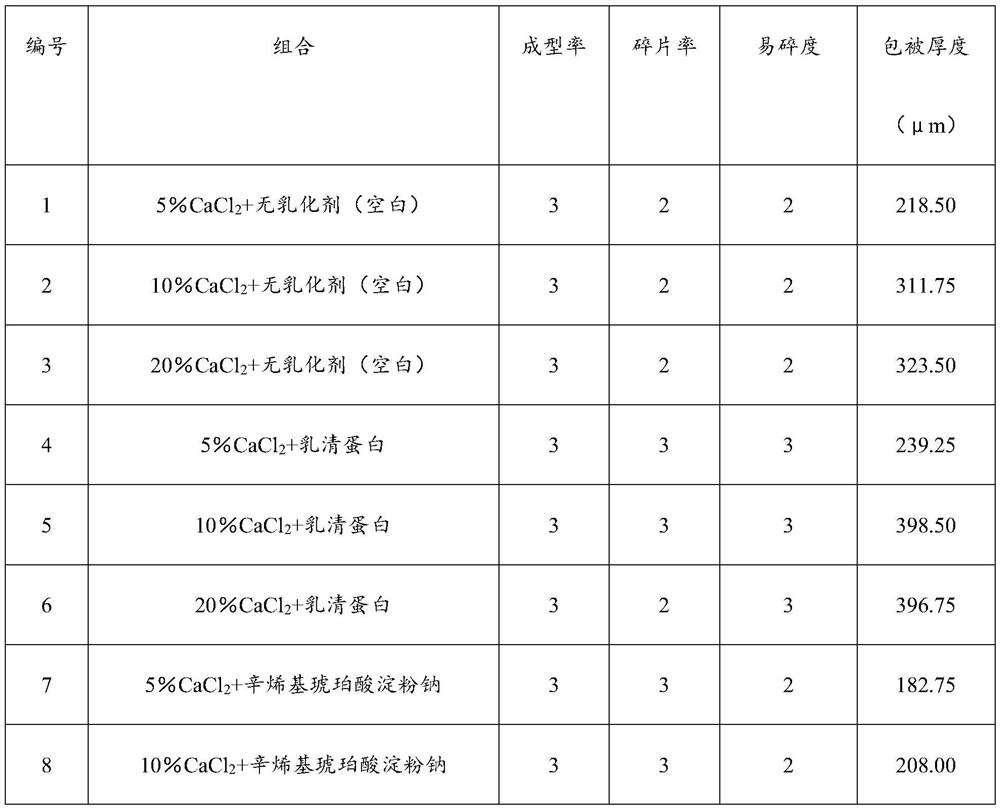

[0036] A method for preparing rumen-passed amino acids, comprising the following steps:

[0037] (1) Take sodium alginate solution, whey protein solution, calcium chloride solution respectively; The volume ratio of sodium alginate solution, whey protein solution, calcium chloride solution is 1: 1: 8; The sodium alginate The concentration of the solution is 1.5% w / w; the concentration of the whey protein solution is 5% w / w; the concentration of the calcium chloride solution is 10% w / w;

[0038] (2) Weigh the amino acid, then add it into the whey protein solution weighed in step (1), and stir for 0.5h; the concentration of the amino acid in the whey protein solution is 8% w / w; the amino acid is lysine acid;

[0039] (3) Add the mixed solution obtained in step (2) into the sodium alginate solution weighed in step (1), and heat and stir; the heating and stirring time is 0.5h; the heating and stirring temperature is 50°C;

[0040] (4) Titrate the mixed solution in step (3) into t...

Embodiment 2

[0043] A method for preparing rumen-passed amino acids, comprising the following steps:

[0044] (1) Take sodium alginate solution, whey protein solution, calcium chloride solution respectively; The volume ratio of sodium alginate solution, whey protein solution, calcium chloride solution is 3: 3: 12; The sodium alginate The concentration of the solution is 1.5% w / w; the concentration of the whey protein solution is 5% w / w; the concentration of the calcium chloride solution is 10% w / w;

[0045] (2) Weigh the amino acid, then add it into the whey protein solution weighed in step (1), and stir for 1.5h; the concentration of the amino acid in the whey protein solution is 12% w / w; the amino acid is methionine;

[0046] (3) Add the mixed solution obtained in step (2) into the sodium alginate solution weighed in step (1), and heat and stir; the heating and stirring time is 1.5 h; the heating and stirring temperature is 55° C.;

[0047] (4) Titrate the mixed solution in step (3) int...

Embodiment 3

[0050] A method for preparing rumen-passed amino acids, comprising the following steps:

[0051] (1) Take sodium alginate solution, whey protein solution, calcium chloride solution respectively; The volume ratio of sodium alginate solution, whey protein solution, calcium chloride solution is 2: 2: 10; The sodium alginate The concentration of the solution is 1.5% w / w; the concentration of the whey protein solution is 5% w / w; the concentration of the calcium chloride solution is 10% w / w;

[0052] (2) Weigh the amino acid, then add it into the whey protein solution weighed in step (1), and stir for 1h; the concentration of the amino acid in the whey protein solution is 10% w / w; the amino acid is lysine ;

[0053] (3) Add the mixed solution obtained in step (2) into the sodium alginate solution weighed in step (1), and heat and stir; the heating and stirring time is 1 h; the heating and stirring temperature is 52° C.;

[0054] (4) Titrate the mixed solution in step (3) into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com