Efficient pig farm based on heat pump exchange system

A heat exchange system and exchange system technology are applied in the fields of thermal insulation and airtight pig houses, energy saving, environmental protection and high efficiency pig farms. Benefit, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

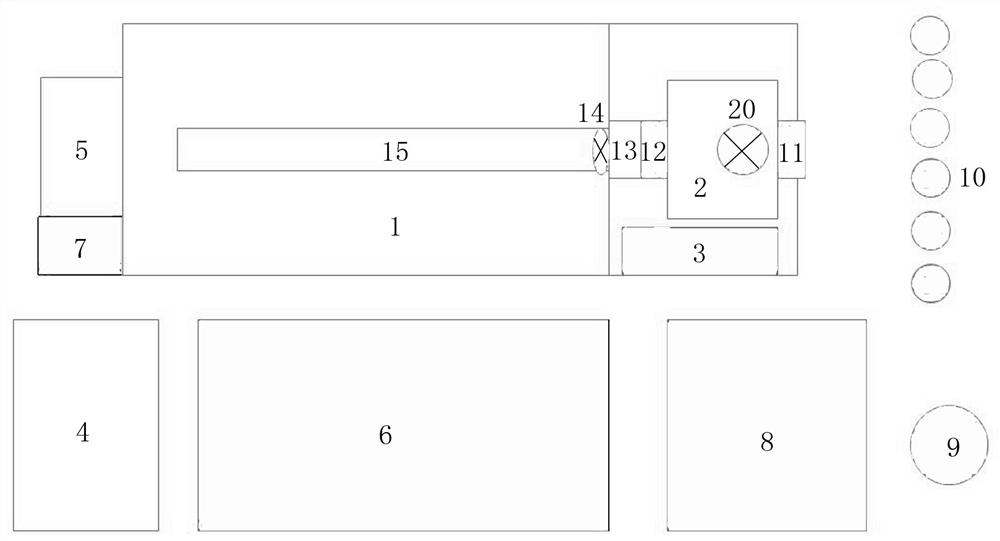

[0035] A high-efficiency pig farm based on a heat pump exchange system, such as figure 1As shown, the main body is passed by the insulation and closed pig house 1, pig house exhaust heat exchange system 2, ground source heat pump system (including heat pump host 3, valve system, control system, terminal heat exchanger 13, etc.), pig farm employees living area 4 , Office area 5, water storage pool 6, hot water storage device 7, stain treatment facility 8, condensation tower 9 and ground source well 10, etc.

[0036] Insulation and closed pig house 1 can be kept different kinds of pigs by installing different facilities.

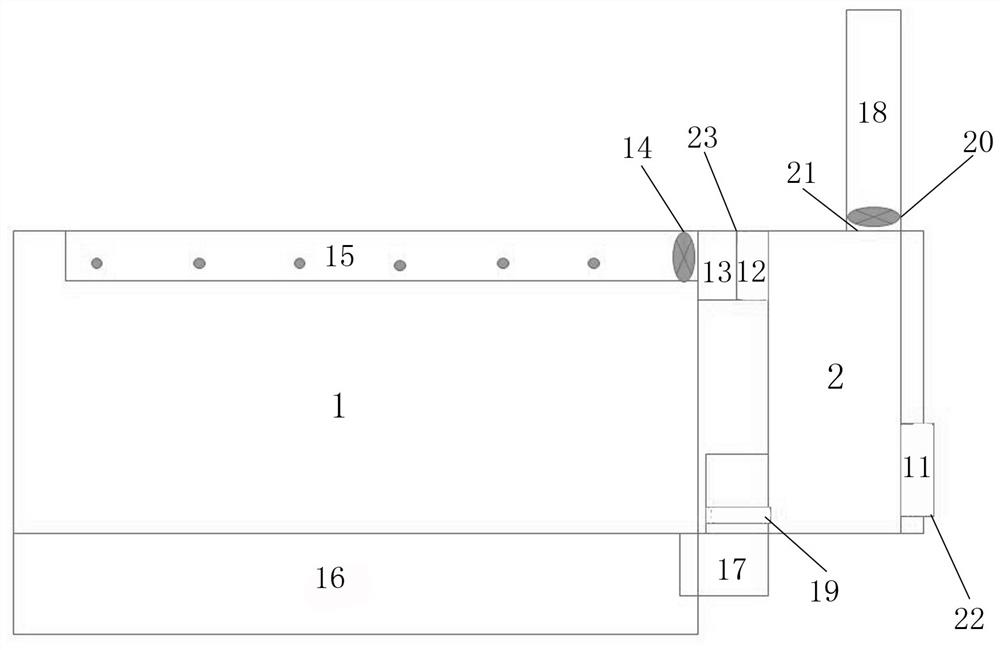

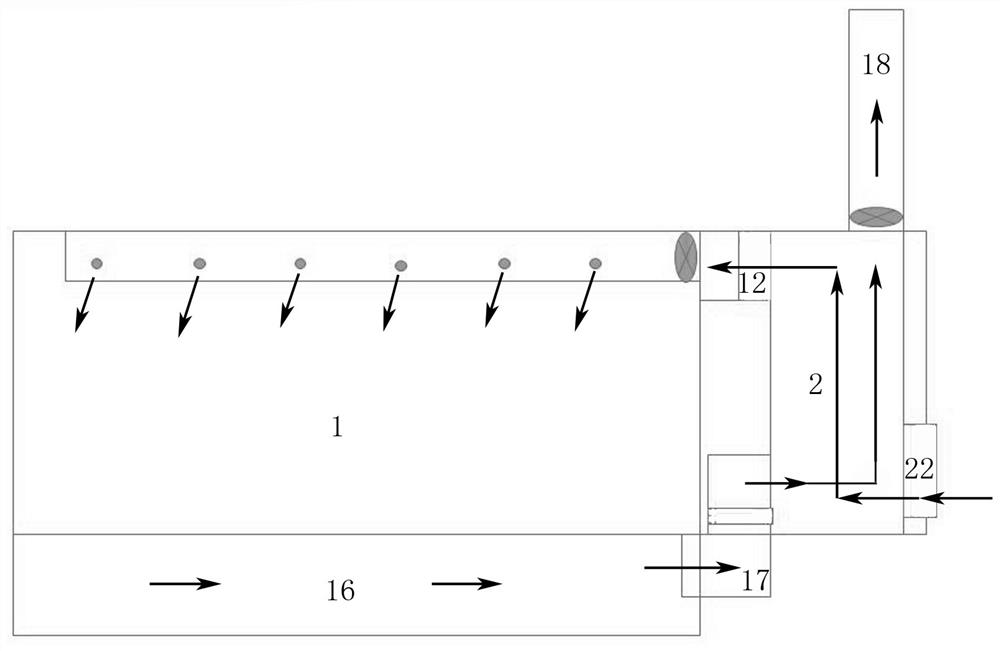

[0037] Such as figure 2 As shown, the pig house exhaust heat exchange system is located next to the pig house 1; the inner port of the pig house exhaust heat exchange system 2 is used as the pig house exhaust gas end 17, and the pig house exhaust gas end 17 is located in the pig house 1 Inside the groove 16, the exhaust gas filter 19 is mounted in the pig house in...

Embodiment 2

[0047] A high-efficiency pig farm based on the heat pump exchange system, the main body is passed from the insulation and closed pig house (pig house is divided into independent pig house I1-1, pig house II1-2 and pig house III1-3), pig house exhaust heat exchange System 2, ground source heat pump system (heat pump host 3, valve system, control system, terminal heat exchanger 13, etc.), pig farm employees 4, office area 5, water storage pool 6, hot water storage device 7, feces The treatment facility 8, the condensation tower 9 and the ground source well 10 are constituted.

[0048] The structure and principles of the insulation close pigstation of the present embodiment are the same as that of Example 1, no repetition.

[0049] This embodiment is different from the first embodiment by transferring heat through the heat pump different facilities of the pig field, such as Figure 6 Down:

[0050] (1) If calculated, the total amount of heat generated by the pig house I1-1 and the tot...

Embodiment 3

[0055] A high-efficiency pig farm based on a heat pump exchange system, such as Figure 7 As shown, the body is composed of a multi-layer pig house with insulation and closed, and the remaining facilities are the same as in Example 1 by installing different facilities, and the remaining facilities are the same, and the difference is that Figure 8 As shown, the pig house exhaust end of each pig house is collected from the high-altitude exhaust pipe.

[0056] This embodiment is the same as that of Example 1 through the ground source heat pump system in different facilities, and no longer repetition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com