Magnetorheological-fluid-based planetary-gear-type differential mechanism with self-locking function

A magnetorheological fluid and planetary gear technology, applied in the field of automobile transmission, can solve the problems of high processing requirements, complex differential structure, wear and friction heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail in conjunction with the following, so that those skilled in the art can implement it with reference to the description.

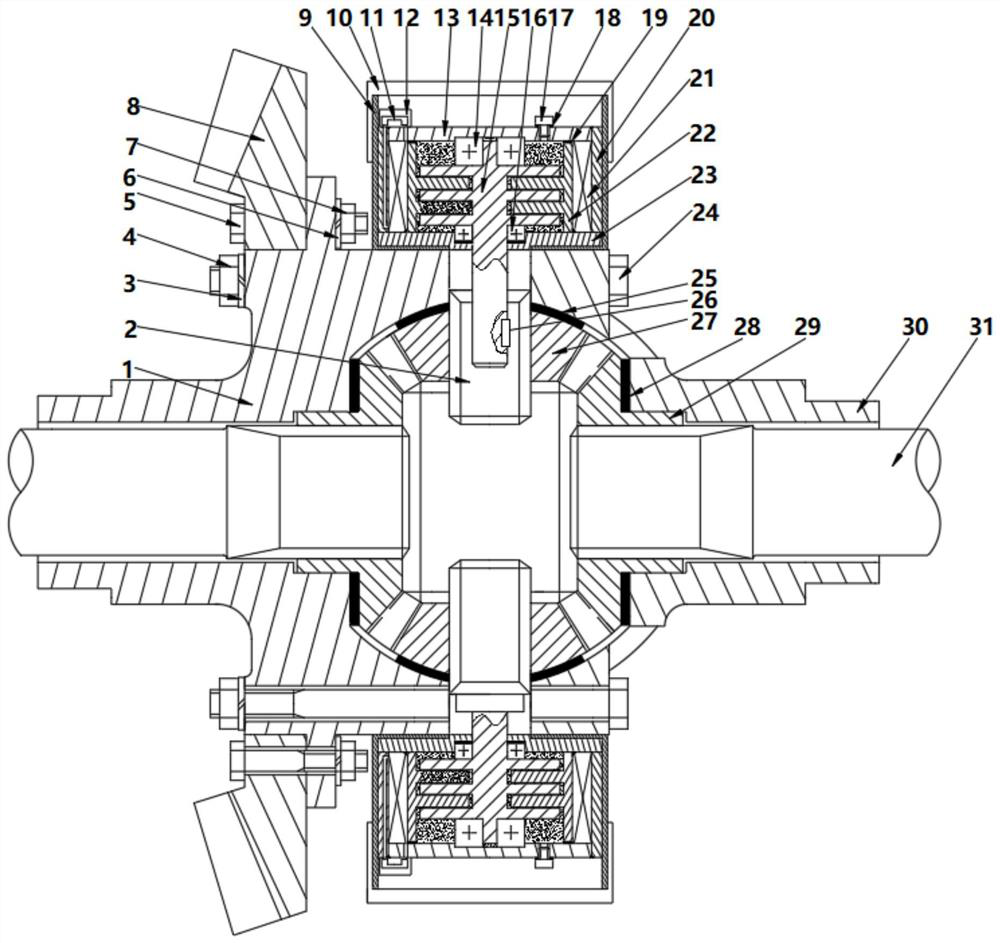

[0059] Such as figure 1 As shown, the present invention provides a magneto-rheological fluid-based planetary gear differential with self-locking function, which specifically includes: differential group, four magneto-rheological device groups and sealing groups, differential group Play the role of reducing speed and increasing torque, changing torque direction and vehicle differential speed.

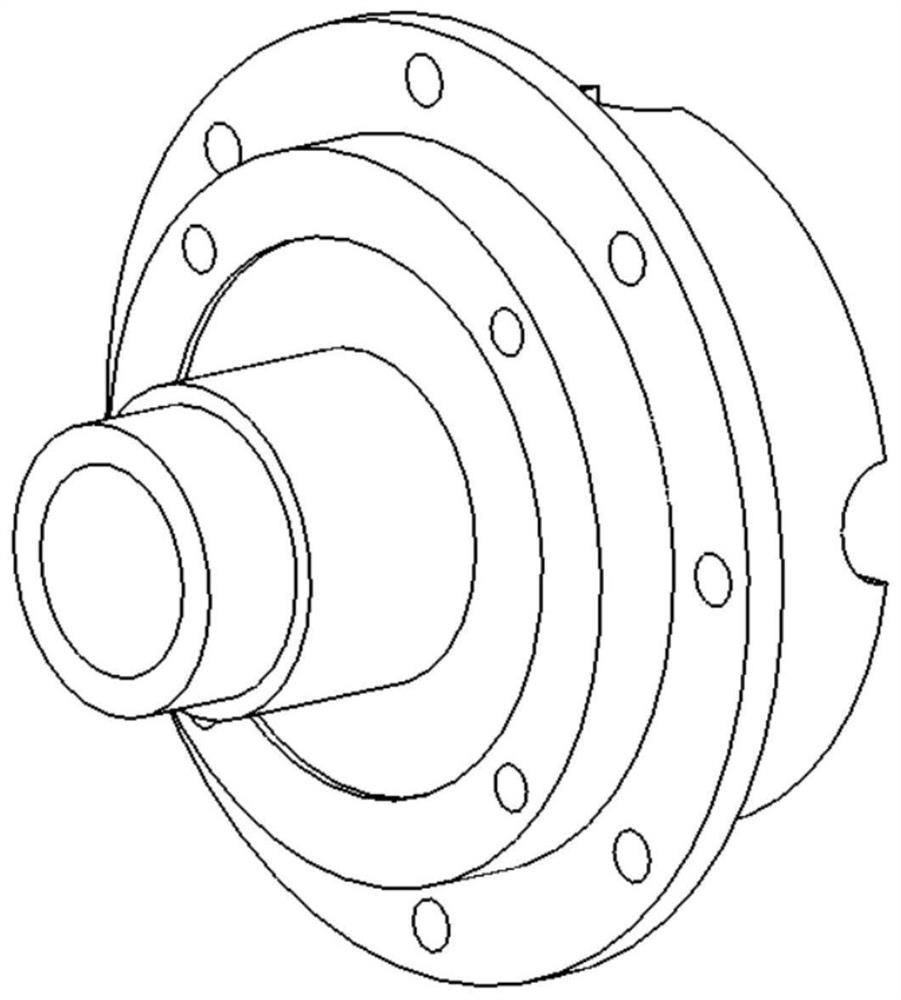

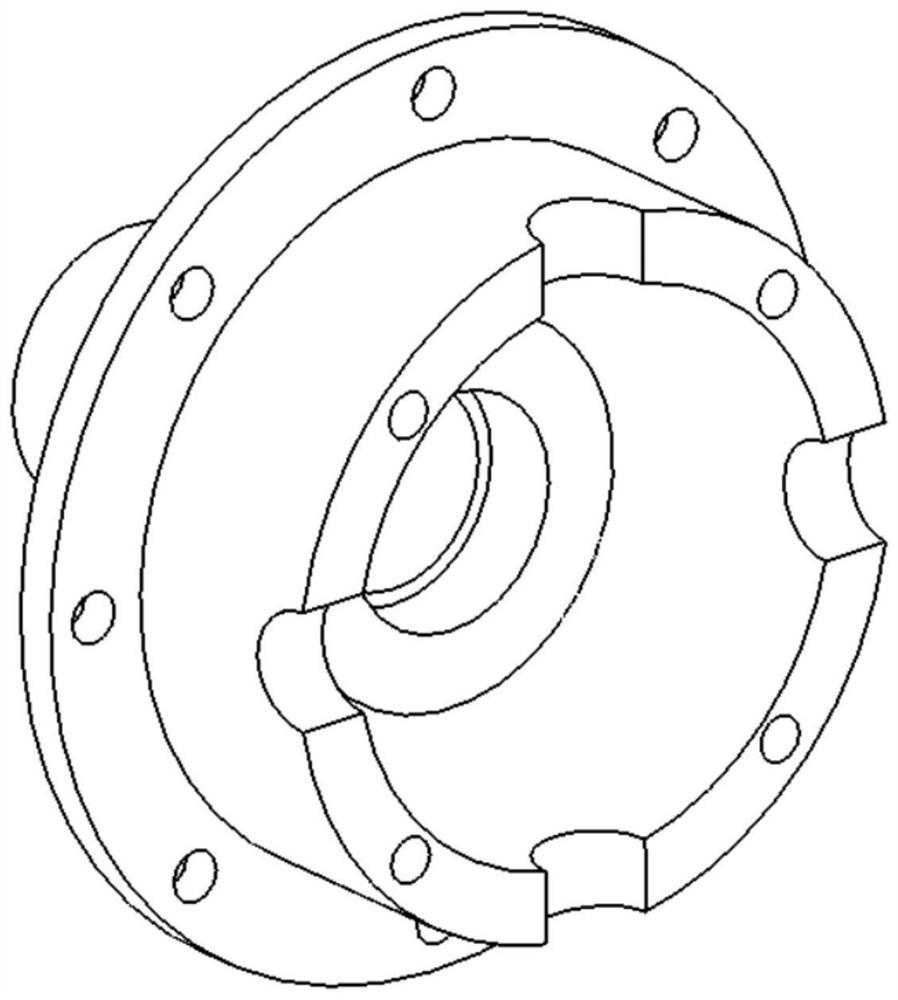

[0060] Among them, such as figure 2 , image 3 As shown, the differential group includes: a first housing, two side gears 124 and four planetary gears 122, and the first housing includes: a front differential housing 101 and a rear differential housing 102 , the first housing is a cylindrical structure, which is the installation base of the internal gear of the differential, and the front differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com